雙相 2205 不銹鋼簡介

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage複式 2205 應用

- 壓力容器、高壓儲罐、高壓管道、熱交換器(化學加工行業)。

- 油氣管道、換熱器管件。

- 污水處理系統。

- 紙漿和造紙工業分級機、漂白設備、儲存和處理系統。

- 高強度、耐腐蝕環境下的轉軸、壓輥、葉片、葉輪等。

- 船或卡車的貨箱

- 食品加工設備

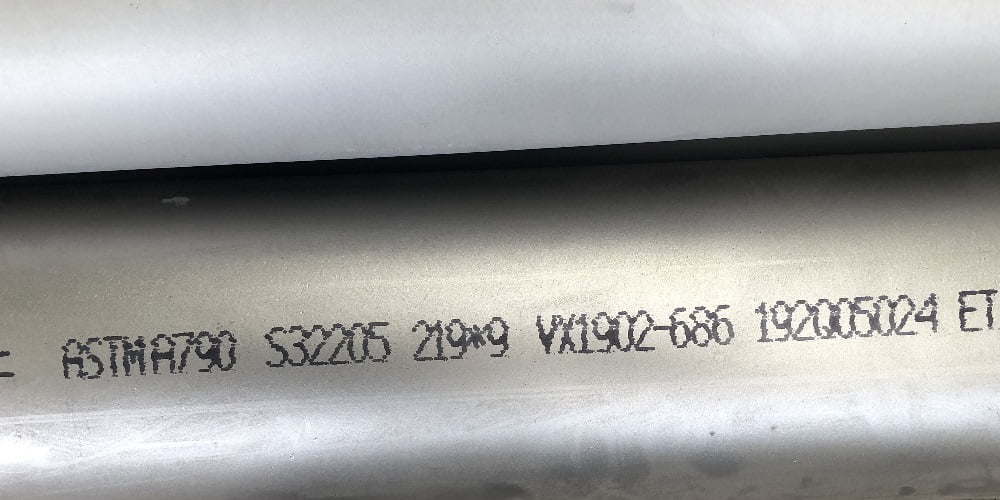

標準

- ASTM/ASME…………..A240 UNS S32205/S31803

- 歐洲標準…………..1.4462 X2CrNiMoN 22.5.3

- AFNOR……………….Z3 CrNi 22.05 AZ

- DIN…………………….W.編號 1.4462

耐腐蝕性能

均勻腐蝕

由於鉻含量(22%)、鉬(3%)和氮含量(0.18%),2205在大多數環境下的耐腐蝕性優於316L和317L。

耐局部腐蝕

2205 雙相不銹鋼中鉻、鉬和氮的含量使其在氧化和酸性溶液中具有很強的耐點蝕和縫隙腐蝕能力。

耐應力腐蝕

不銹鋼的雙相顯微組織有助於提高不銹鋼的抗應力腐蝕開裂性能。在一定的溫度、應變、氧和氯化物存在下,奧氏體不銹鋼會發生氯化物應力腐蝕。由於這些條件不易控制,304L、316L、317L的使用在這方面受到限制。

抗腐蝕疲勞

2205雙相鋼的高強度和耐蝕性使其具有很高的腐蝕疲勞強度。加工設備易受腐蝕環境和負載循環的影響,而 2205 的特性非常適合此類應用。

雙相 2205 結構

2205的化學成分經過1900°/1922°F(1040°/1080°C)固溶退火處理後可獲得理想的顯微組織50 α / 50 γ。如果熱處理溫度高於 2000°F,可能會導致鐵素體成分增加。與其他雙相不銹鋼一樣,2205 合金容易析出金屬間相。金屬間相在 1300°F 和 1800°F 之間析出,在 1600°F 時析出速度最快。因此,我們需要對2205進行測試,確保沒有金屬間相。測試參照 ASTM A 923。

熱成型

We recommend that the forming should be done at temperatures below 600°F as much as possible. During the hot forming process, the entire workpiece should be heated as a whole, and should be carried out in the temperature range of 1750°F to 2250°F.Alloy 2205 is very soft at this temperature. If the temperature is too high, 2205 alloy is prone to hot tearing. If it is lower than this temperature, austenite will fracture. Below 1700°F, the intermetallic phase will form quickly due to the influence of temperature and deformation.After the hot forming is completed, it should be solid-solution annealed at a minimum temperature of 1900°F and quenched to restore its phase balance, toughness and corrosion resistance.We do not recommend stress relief, but if you must do so, the material should be solid solution annealed at a minimum temperature of 1900°F, then quickly cooled and water quenched.冷成型

2205 合金可以切割和冷成型。但由於2205合金本身強度高、硬度高,比奧氏體鋼需要更多的冷成型加工。也正是因為它的強度高,所以必須充分考慮回彈。

熱處理

Alloy 2205 should be annealed at a minimum temperature of 1900°F, then rapidly cooled and water quenched. This treatment is used for solution annealing and stress relief.If the stress relief treatment is performed at a temperature lower than 1900°F, it is easy to cause the precipitation of harmful metallic or non-metallic phases.可加工性

在高速機床上,2205合金的進給量和切削速度與316L相同。若使用碳化刀,切割速度較316L降低約20%。機器及其組件的性能在這裡起著關鍵作用。

焊接

The weldability of 2205 alloy is very good. The required performance of 2205 alloy is that the weld metal and thermally deteriorated parts still maintain the same corrosion resistance, strength and toughness as the base metal.The welding of 2205 is not difficult, but the welding procedure needs to be designed so that after welding, it can maintain a good phase balance and avoid the precipitation of harmful metal phases or non-metal phases.2205 can be welded in the following equipment: GTAW (TIG); GMAW (MIG); SMAW (“stick” electrode); SAW; FCW; and PAW特徵:

1. 2205 duplex stainless steel alloy as compared with austenitic stainless steel 316L and 317L, 2205 superior performance in resistance to pitting and crevice corrosion aspect, it has a high corrosion resistance, as compared with austenite, it The coefficient of thermal expansion is lower and the thermal conductivity is higher.

2. Compared with austenitic stainless steel, duplex stainless steel 2205 alloy has twice its compressive strength. Compared with 316L and 317L, the designer can reduce its weight. Alloy 2205 is especially suitable for the temperature range of -50°F/+600°F. Under strict restrictions (especially for welded structures), it can also be used at lower temperatures.雙相 2205 化學成分

Performance supplement: main component: 22Cr-5.3Ni-3.2Mo-0.16N; national standards: NAS 329J3L, UNS S32205/S31803, DIN/EN 1.4462, ASTM A240, ASME SA-240; mechanical properties: tensile strength: σb≥ 640Mpa; Elongation: δ≥25%; Typical working conditions: 20% dilute sulfuric acid, below 60℃, annual corrosion rate <0.1mm; Matching welding wire: ER2209.1. Chemical composition (JIS G 4305-005) (wt%)| 化學成分 | C | 和 | 錳 | 磷 | 小號 | 鉻 | 你 | 莫 | ñ |

| 標準 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.03 | 21.0~24.0 | 4.5~6.5 | 2.5~3.5 | 0.08~0.2 |

| 一般的 | 0.025 | 0.6 | 1.5 | 0.026 | 0.001 | 22.5 | 5.8 | 3.0 | 0.16 |

2.性能(JIS G 4305-2005)

| 區分 | 機械性能 | 評論 | | |

| Ys(兆帕) | Ts(兆帕) | 他 (%) | 高壓 | 2.0噸/2B |

| ≥450 | ≥620 | ≥25% | ≥18 | ≤ 320 |

| 500 | 670 | 35% | 27 | 280 |

3、物理性能

| 密度(克/立方厘米) | 磁的 | 比熱(J/gC) | 導熱係數100C(W/m. | 熱膨脹率20~100C(10/C) |

| 7.8 | 有 | 0.45 | 19.0 | 13.7 |

雙相 2205 機械性能

| 2205雙相不銹鋼的室溫力學性能 |

| 鋼級 | 產品規格 | 抗拉強度 | 屈服強度 | 伸長 | |

| 兆帕 | 兆帕 | % | |

| 00Cr22Ni5Mo3N | Φ20mm,棒材 | ≥680 | ≥450 | ≥25 | |

| 新加坡武裝部隊 2205 | 壁厚≤20mm,管材 | 680/880 | >450 | >25 | |

| 毛坯厚度≤200mm,鍛件 | 680/880 | >410 | >25 [1] | |

2205雙相不銹鋼的高溫力學性能

|

| 鋼級 | 產品規格 | 抗拉強度 | 屈服強度 | 伸長 | 溫度 |

| 兆帕 | 兆帕 | % | °C |

| 00Cr22Ni5Mo3NSAF 2205 | Φ20mm,棒材 | 710 | 470 | 37 | 100 |

| 680 | 393 | 32 | 200 |

| 650 | 380 | 30 | 300 |

| | | | |

| 壁厚≤20mm,管材 | >630 | >370 | | 100 |

| >580 | >330 | | 200 |

| >560 | >310 | | 300 |

| | | | |

| 毛坯厚度≤200mm,鍛件 | >630 | >365 | | 100 |

| >580 | >315 | | 200 |

| >560 | >285 | | 300 |

雙相 2205 鋼的優勢

- 2205 stainless steel plate, 2205 stainless steel, duplex stainless steel 2205, 2205 stainless steel materials, are Swedish stainless steel grades.

The difference between duplex 2205 stainless steel plate and austenitic 304 stainless steel plate

- The yield strength is more than twice that of ordinary austenitic stainless steel, and it has the necessary requirements for forming

Sufficient plasticity. The wall thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenite, which is beneficial to reduce costs.

- 它具有優異的抗應力腐蝕開裂性能。即使是合金含量最低的雙相不銹鋼,也比奧氏體不銹鋼具有更高的抗應力腐蝕開裂能力,尤其是在含有氯離子的環境中。應力腐蝕是普通奧氏體不銹鋼難以解決的突出問題。

- 許多介質中最常用的2205雙相不銹鋼的耐蝕性優於普通316L奧氏體不銹鋼,而超級雙相不銹鋼則具有極高的耐蝕性。在某些介質中,如醋酸和甲酸甚至可以代替高合金奧氏體不銹鋼甚至耐腐蝕合金。

- 具有良好的抗局部腐蝕性能。與相同合金含量的奧氏體不銹鋼相比,其耐磨腐蝕性能和抗疲勞腐蝕性能均優於奧氏體不銹鋼。

- 線膨脹係數低於奧氏體不銹鋼,與碳鋼接近。適用於與碳鋼連接,具有重要的工程意義,如製作複合板或襯裡等。

- 無論是在動載還是靜載條件下,它都比奧氏體不銹鋼具有更高的能量吸收能力。這是為了應對碰撞、爆炸等突發事故的結構件。雙相不銹鋼具有明顯的優勢,具有實際應用價值。

雙相 2205 不銹鋼缺點

與奧氏體不銹鋼相比,雙相不銹鋼的缺點如下:

- 應用的普遍性和通用性不如奧氏體不銹鋼。例如,它的使用溫度必須控制在250攝氏度以下。

- 其塑韌性低於奧氏體不銹鋼,冷熱加工工藝和成型性能不如奧氏體不銹鋼。

- 存在中溫脆化區,需要嚴格控制熱處理和焊接的工藝體系,避免有害相的出現,破壞性能。

雙相2205不銹鋼板與鐵素體410不銹鋼板的區別:綜合力學性能優於鐵素體不銹鋼,特別是塑韌性,不像鐵素體不銹鋼那樣對脆性敏感。

- 除耐應力腐蝕外,其他耐局部腐蝕能力均優於鐵素體不銹鋼。

- 冷加工工藝性能和冷成形性能遠優於鐵素體不銹鋼。

- 焊接性能也遠優於鐵素體不銹鋼。一般焊前不需預熱,焊後不需熱處理。

- 應用範圍較鐵素體不銹鋼廣。與鐵素體不銹鋼相比,雙相不銹鋼的缺點是:合金元素含量高,價格相對較高。通常,鐵氧體不含鎳。

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage

The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel .This feature enables designers to reduce weight when designing products, making this alloy more cost-effective than 316 and 317L.2205 alloy is particularly suitable for the temperature range of -50°F/+600°F. For applications beyond this temperature range, this alloy can also be considered, but there are some limitations, especially when applied to welded structures.Application Structure Processing Chemical composition Mechanical Properties Advantage Disadvantage