產品介紹:

C90810高錫青銅是一種基於銅的合金,以其出色的強度,耐磨性和耐腐蝕性而聞名。這種合金在需要高負載能力和低速操作的應用中特別有價值。高錫含量有助於其出色的機械性能,使其成為各種工業應用的理想選擇。

C90810的化學組成

| 元素 | 百分比 (%) | 功能 |

|---|

| 和 | 餘 | 賤金屬,提供延展性和導電性 |

| 錫 | 11.00-13.00 | 提高力量,硬度和耐磨性 |

| 鉛 | 0最大.25 | 增強可加工性 |

| 鋅 | 0.30 最大 | 提高鑄造的流動性 |

| 鐵 | 0.15 最大 | 晶粒細化劑,增加強度 |

| 磷 | 0.15-0.80 | 脫氧劑,改善流動性 |

| 你 | 0.50 最大 | 增加強度和耐腐蝕性 |

| 鋁 | 0.005 最大 | 脫氧劑 |

| 小號 | 0.05 最大 | 提高機械加工性能 |

| 銻 | 0最大.20 | 增加硬度 |

| 和 | 0.005 最大 | 脫氧劑 |

筆記:

- 在確定Cu min。中,用計算和Cu + Ni Cuck。

- 對於連續鑄件,P最高為1.5%。

- Ni值包括Co。

- CU +指定元素的總和,99.4%。單個值表示最大值。

C90810的機械性能

| 財產 | 價值 | 單元 |

|---|

| Brinell硬度(500千克負載) | 95典型 | BHN |

| 機械加工性等級 | 20 | – |

| 密度 | 0.323 | lb/in³在68°F(20°C)下 |

| 抗拉強度 | 40,000 | 磅/平方英寸 |

| 屈服強度 | 20,000 | 磅/平方英寸 |

| 伸長 | 20 | % |

| 彈性模量 | 15 | x 10^6 psi |

不同溫度下的性能

| 溫度範圍 | 性能特點 | 推薦使用 |

|---|

| 低溫(-50°C 至 0°C) | 保持延展性和韌性 | 合適的 |

| 室溫(20°C 至 25°C) | 最佳強度和耐磨性 | 理想的 |

| 溫度升高(100°C至200°C) | 保留力量,但可能會稍微軟化 | 可以接受 |

| High Temperature (>200°C) | 不建議長時間使用 | 不建議 |

產業應用

| 產業 | 應用 | 主要優點 |

|---|

| 工業機械 | 軸承,齒輪,軸,蠕蟲齒輪 | 高磨損阻力 |

| 海洋 | 泵浦葉輪、閥體 | 耐腐蝕性能 |

| 建造 | 可移動橋樑部件、橋樑轉盤 | 力量和耐用性 |

| 汽車 | 活塞環 | 低摩擦係數 |

| 活力 | 蒸汽配件 | 耐熱性 |

| 礦業 | 重型襯套 | 衝擊阻力 |

| 航天 | 起落架的襯套 | 高負載容量 |

| 油和氣 | 閥門組件 | 惡劣環境中的耐腐蝕性 |

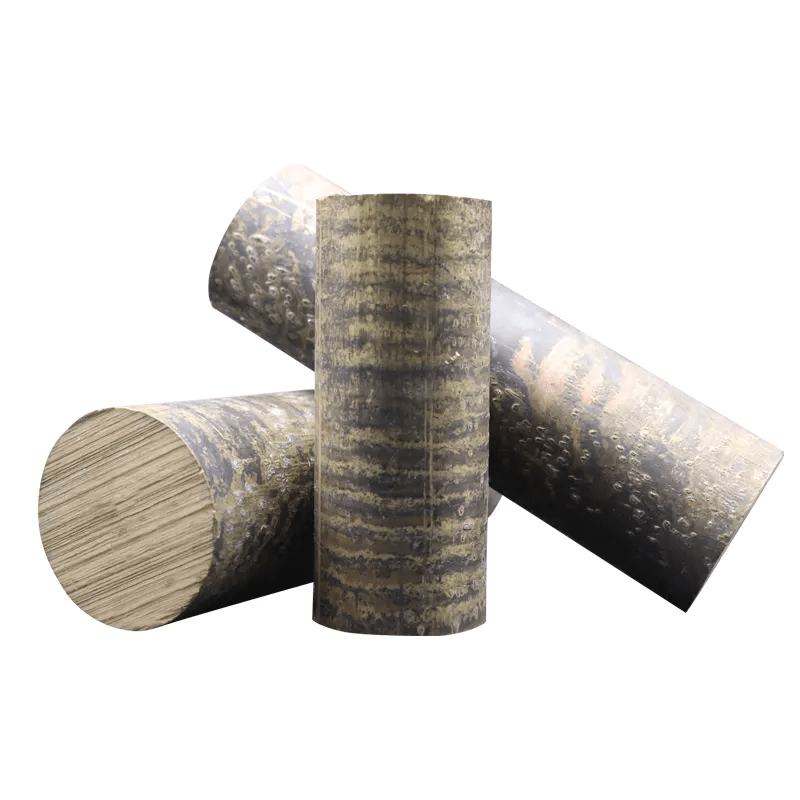

形狀和尺寸可供選擇

| 形狀 | 尺寸範圍 | 標準長度 |

|---|

| 固體 | 1英寸至6英寸O.D. | 144英寸 |

| 管 | 1英寸至6英寸O.D. | 144英寸 |

| 長方形 | 最多10英寸 | 144英寸 |

| 盤子 | 最多24英寸厚度 | 96“ x 240” |

| 桿 | 0.25英寸至12英寸 | 144英寸 |

| 自定義形狀 | 根據要求 | 各種 |

可用表格

| 形式 | 典型用途 | 可用性 |

|---|

| 半整合 | 進一步處理 | 常見的 |

| 磨坊庫存 | 直接使用 | 廣泛可用 |

| 近網的形狀 | 最小加工 | 應要求 |

| 酒吧庫存 | 加工 | 標準 |

| 盤子 | 大型平坦組件 | 常見的 |

| 輪廓或結構形狀 | 特定應用 | 應要求 |

| 鍛件 | 高強度部件 | 有限的 |

| 鑄件 | 複雜形狀 | 常見的 |

生產標準和合規性

| 標準/合規性 | 地區 | 關聯 |

|---|

| 聯邦安全飲用水法 - SDWA | 美國 | 水安全 |

| S. 3874 聯邦飲用水含鉛量減少法 | 美國 | 鉛含量 |

| 加州AB1953 | 美國加利福尼亞 | 鉛含量 |

| 佛蒙特州法案 193 | 美國佛蒙特州 | 鉛含量 |

| ASTM B505 | 國際的 | 連續鑄造銅合金 |

| ASTM B271 | 國際的 | 銅鹼合金離心鑄件 |

| ISO 1338 | 國際的 | 鑄造銅合金 |

| 他H5111 | 日本 | 青銅鑄件 |

各國標準及相應等級

| 國家 | 標準 | 對應等級 |

|---|

| 美國 | 我們 | C90810 |

| 德國 | 從 | 銅錫12 |

| 日本 | 日標 | CAC704 |

| 英國 | 學士學位 | HTB1 |

| 法國 | nf | 銅錫12 |

| 意大利 | 統一 | 銅錫12 |

| 俄羅斯 | 國家標準 | Bro12 |

| 中國 | 國標 | Z銅錫12 |

| 國際的 | 國際標準化組織 | 銅錫12 |

焊接特性

| 焊接方法 | 適應性 | 筆記 | 預熱溫度 |

|---|

| 氣焊 | 好的 | 使用磷青銅填充棒 | 150-200°C |

| 提格焊接 | 優秀的 | 使用純氬屏蔽氣體 | 根據需要 |

| 我焊接 | 好的 | 使用青銅填充線 | 根據需要 |

| 棒焊接 | 公平的 | 使用青銅電極 | 根據需要 |

| 電阻焊 | 貧窮的 | 不建議 | 不適用 |

| 電子束焊接 | 好的 | 用於精確應用 | 根據需要 |

| 激光焊接 | 公平的 | 需要仔細控制 | 根據需要 |

加工特性

| 過程 | 適應性 | 筆記 | 關鍵考慮 |

|---|

| 加工 | 好的 | 可加工性額定值為20 | 工具選擇 |

| 成型 | 公平的 | 由於錫含量高,成形性有限 | 避免過度變形 |

| 鍛造 | 貧窮的 | 不建議 | 不適用 |

| 鑄件 | 優秀的 | 沙子和離心鑄造的理想 | 適當的冷卻速率 |

| 擠壓 | 貧窮的 | 通常不會擠出 | 不適用 |

| 深圖 | 貧窮的 | 有限的延展性 | 不建議 |

| 旋轉 | 公平的 | 通過適當的技術可能 | 避免工作硬化 |

| 提取 | 好的 | 適合精確尺寸 | 工具穿 |

拋光特徵

| 拋光方法 | 結果 | 推薦的磨料 |

|---|

| 機械拋光 | 良好的表面飾面可實現 | 氧化鋁或鑽石化合物 |

| 化學拋光 | 中等結果 | 專有解決方案 |

| 電解拋光 | 非常適合高光澤效果 | 基於磷酸的電解質 |

| 拋光 | 高光澤 | 柔軟的布輪和精細的磨料 |

| 拍打 | 精確表面 | 鑽石或碳化矽化合物 |

| 磨練 | 適合圓柱形表面 | 粘合的磨石石 |

熱處理

| 熱處理 | 溫度範圍 | 目的 | 冷卻方式 |

|---|

| 退火 | 550-650°C | 緩解壓力和軟化 | 緩慢冷卻 |

| 溶液處理 | 不適用 | C90810不能熱處理 | 不適用 |

| 時效硬化 | 不適用 | C90810不適合年齡 | 不適用 |

| 壓力緩解 | 260-370°C | 減少內應力 | 風冷 |

| 規範化 | 通常不執行 | 不適用 | 不適用 |

| 淬火 | 不建議 | 可能導致失真 | 不適用 |

冷處理特徵

| 過程 | 適應性 | 筆記 | 替代建議 |

|---|

| 冷加工 | 有限的 | 高錫含量可降低延展性 | 如有必要,請考慮熱門工作 |

| 冷拔 | 貧窮的 | 不建議 | 改用加工 |

| 冷軋 | 貧窮的 | 不建議 | 考慮鑄造或機械形式 |

| 冷門 | 不宜 | 太脆了 | 使用加工或鑄造 |

| 冷鍛 | 不宜 | 缺乏必要的延展性 | 考慮熱鍛造或鑄造 |

| 噴丸強化 | 公平的 | 可以改善表面特性 | 謹慎使用 |

C90810的優點和缺點

| 好處 | 缺點 | 注意事項 |

|---|

| 高強度 | 有限的成形性 | 最小成型的設計 |

| 優異的耐磨性 | 與一些青銅相比,成本更高 | 考慮關鍵應用 |

| 良好的耐腐蝕性 | 不適合高速應用 | 在低到中等的速度設置 |

| 低摩擦係數 | 有限的冷工作能力 | 設計或加工形式的設計 |

| 適用於重負載 | 不能熱處理 | 選擇不需要熱處理的應用 |

| 良好的機械加工性 | 密度相對較高 | 考慮設計重量 |

| 出色的軸承特性 | 在非常低的溫度下容易受到錫害的影響 | 避免長時間的暴露在13°C以下 |

| 良好的尺寸穩定性 | 可能很難焊接 | 使用適當的焊接技術 |

| 耐海水腐蝕 | 不如鋼 | 在適當的負載條件下使用 |

| 低磁滲透性 | 比黃銅高的成本 | 證明具有性能要求的成本合理 |

類似產品

| 合金 | UNS編號 | 主要組成 | 主要差異 |

|---|

| C90700 | C90700 | Cu-Sn-Zn | 下錫,較高的鋅含量 |

| C91100 | C91100 | 與sn | 較高的錫含量,沒有鉛 |

| C93200 | C93200 | 與SN-PB | 較高的鉛含量以提高可加工性 |

| C95400 | C95400 | 銅鋁鐵 | 具有不同特性概況的鋁製青銅 |

| C95500 | C95500 | 銅鋁鎳鐵 | 強度更高的鎳鋁青銅 |

| C86300 | C86300 | cu-mn-ni-fe | 強度更高的錳青銅 |

| C92200 | C92200 | CU-SN-PB-Zn | 海軍M槍金屬與不同的成分 |

C90810與類似產品的比較

| 財產 | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| 拉伸強度(PSI) | 40,000 | 36,000 | 45,000 | 35,000 | 90,000 |

| 產量強度(PSI) | 20,000 | 18,000 | 25,000 | 18,000 | 45,000 |

| 伸長率(%) | 20 | 25 | 15 | 20 | 15 |

| 布氏硬度 | 95 | 70 | 100 | 65 | 190 |

| 耐腐蝕性能 | 優秀的 | 好的 | 優秀的 | 好的 | 優秀的 |

| 可加工性 | 好的 | 非常好 | 公平的 | 優秀的 | 公平的 |

| 可焊性 | 公平的 | 好的 | 公平的 | 貧窮的 | 好的 |

| 耐磨性 | 優秀的 | 好的 | 優秀的 | 好的 | 優秀的 |

| 成本 | 高的 | 緩和 | 很高 | 緩和 | 高的 |

| 典型應用 | 重型軸承 | 通用 | 高負載軸承 | 襯套、軸承 | 船用部件 |

結論:

C90810 High Tin Gronze是一種專門的合金,可提供獨特的物業組合,在各種工業應用中都無價。它的高錫含量有助於出色的強度,耐磨性和耐腐蝕性,尤其是在重載的低速設置中。雖然它在高溫和高溫應用方面有局限性,但C90810在海洋工程,工業機械和建築等行業中表現出色。

合金的多功能性在其廣泛的可用形式和尺寸,遵守國際標準以及良好的可加工性方面很明顯。但是,在將C90810納入項目時,設計師和工程師必須考慮其特定特徵,例如有限的冷工作能力和熱處理選擇。

與類似的合金相比,C90810的強度,耐磨性和耐腐蝕性的平衡而脫穎而出。它獨特的屬性概況使其成為這些特徵至關重要的應用程序的理想選擇,證明其在關鍵組件中的成本更高。

總而言之,C90810高錫銅仍然是現代工程中的寶貴材料,在苛刻的其他合金可能不足的環境中提供可靠的性能。