C89835 鉍錫青銅名稱和訊息

C89835鉍錫青銅,最大鉛含量為0.05%。鉍被用作鉛的替代品,具有與鉛基銅合金類似的特性。

C89835 也稱為以下相關術語:CDA 89835、UNS 89835、B04 青銅、無鉛青銅、鉍青銅、銅鉍青銅、無鉛鉍青銅、鉍錫青銅和無鉛鉍錫青銅。

C89835 的優點包括良好的機械加工性、電鍍和拋光特性、較低溫度下的鑄造性以及優異的微觀結構特性。

C89835 是 C932、C836 和 C844 的無鉛替代合金,由 LION COPPER 製造,尺寸最大為 10 吋外徑。 C89835 支持市場對符合法規的無鉛材料的需求。

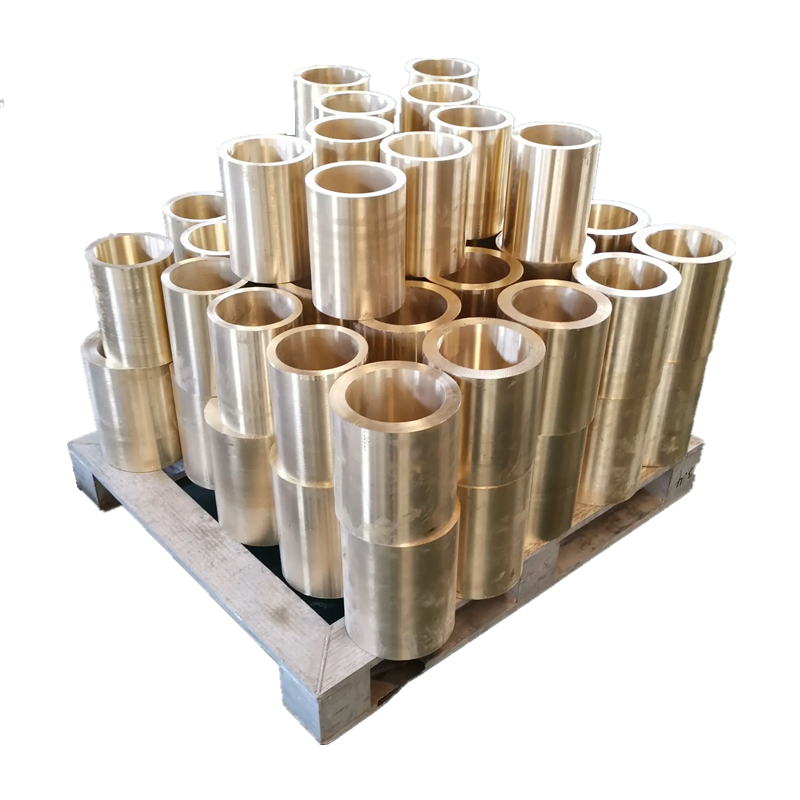

C89835鉍錫青銅產品描述:

形狀/形式:半成品、磨料或近淨形狀、陽極、棒材、鋼坯/大方坯、方形、六角形、板材、型材或結構形狀、扁鋼/矩形棒

合規性:C89835 符合主要立法,包括 (1) 聯邦安全飲用水法案 – SDWA、(2) S.3874 聯邦飲用水鉛減少法案、(3) 加州 AB1953、(4) 佛蒙特州法案 193,並且符合NSF/ANSI/CAN 61-2022 標準

*壁厚請諮詢工廠

典型用途

管道:水龍頭、幫浦組件、管道配件、水暖用品、水泵葉輪

工業:外殼、小齒輪

化學成分

| 銅% | 鉛% | 錫% | 鋅% | 鐵% | % | 在 %1 中 | 鋁% | 雙% | % | 銻% | 和% |

|---|---|---|---|---|---|---|---|---|---|---|---|

CDA提供的化學成分 1Ni值包括Co。 註:Cu + 命名元素總和,至少 99.0%。單一值代表最大值。 | |||||||||||

| 85.00- 89.00 | 0.09 | 6.00- 7.50 | 2.00- 4.00 | 0.20 | 0.10 | 1.00 | 0.005 | 1.70- 2.70 | 0.08 | 0.35 | 0.005 |

可加工性

| 銅合金UNS號 | 機械加工性能等級 | 密度(68°F 時磅/英吋) |

|---|---|---|

| C89835 | 70 | 0.321 |

機械性能

| 拉伸強度,最小值 | 屈服強度,在負載下延伸 0.5% 時,最小值 | 伸長率,最小 2 英吋或 50 毫米 | 布氏硬度(500公斤負載) | 評論 | ||

|---|---|---|---|---|---|---|

| 克西 | 兆帕 | 克西 | 兆帕 | % | 典型的BHN | |

| 30 | 207 | 14 | 97 | 6個 | 65 | |

物理性質

CDA提供的物理特性 | |||||||||||

| 美國習慣法 | 公制 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 熔點 – 液體 | 1855°F | 1012℃ | |||||||||

| 熔點-固相線 | 1445°F | 785℃ | |||||||||

| 密度 | 068°F 時為 .321 磅/英寸 | 20°C 時為 8.89 克/立方厘米 | |||||||||

| 比重 | 8.89 | 8.89 | |||||||||

| 電導率 | 68 °F 時為 14.5 % IACS | 0.084 兆西門子/公分 (20 °C) | |||||||||

| 導熱係數 | 68°F 時為 38.0 Btu/平方英尺/英尺·小時/°F | 20°C 時為 65.8 W/m | |||||||||

| 熱膨脹係數68-392 | 10 · 10-6 每°F (68-392°F) | 17.3 每°C 10-6 (20-200°C) | |||||||||

| 比熱容 | 068°F 時為 .093 Btu/lb/°F | 389.6 焦耳/公斤 20℃ | |||||||||

| 拉伸彈性模量 | 16900 克西 | 116522兆帕 | |||||||||

製造性能

CDA 提供的製造特性 | |||||||||||

| 技術 | 適應性 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 焊接 | 優秀的 | ||||||||||

| 釬焊 | 好的 | ||||||||||

| 氧乙炔焊 | 不建議 | ||||||||||

| 氣體保護電弧焊 | 不建議 | ||||||||||

| 塗層金屬電弧焊 | 不建議 | ||||||||||

| 機械加工性能等級 | 70 | ||||||||||