Ürün tanıtımı:

C90810 Yüksek Kalay Bronz, olağanüstü gücü, aşınma direnci ve korozyon direnciyle bilinen bakır bazlı bir alaşımdır. Bu alaşım özellikle yüksek yük taşıma kapasitesi ve düşük hızlı operasyonlar gerektiren uygulamalarda değerlidir. Yüksek kalay içeriği üstün mekanik özelliklerine katkıda bulunur ve bu da onu çeşitli endüstriyel uygulamalar için ideal bir seçim haline getirir.

C90810'un Kimyasal Bileşimi

| Öğe | Yüzde (%) | İşlev |

|---|

| Cu | Kalan | Ana metal, süneklik ve iletkenlik sağlar |

| sn | 11.00-13.00 | Gücü, sertliği ve aşınma direncini artırır |

| kurşun | 00,25 maksimum | İşlenebilirliği artırır |

| Zn | 00,30 maksimum | Dökümde akışkanlığı artırır |

| Fe | 00,15 maksimum | Tahıl inceltici, gücü arttırır |

| P | 00,15-0,80 | Deoksidizer, akışkanlığı artırır |

| İçinde | 00,50 maksimum | Mukavemeti ve korozyon direncini artırır |

| Al | 00,005 maksimum | Deoksidatör |

| S | 00,05 maksimum | İşlenebilirliği artırır |

| Sb | 00,20 maksimum | Sertliği artırır |

| Ve | 00,005 maksimum | Deoksidatör |

Notlar:

- Cu min.'in belirlenmesinde Cu, Cu + Ni olarak hesaplanabilir.

- Sürekli dökümler için P maksimum %1,5 olacaktır.

- Ni değeri Co'yu içerir.

- Cu + adı geçen elementlerin toplamı, �,4 min. Tek değerler maksimumları temsil eder.

C90810'un Mekanik Özellikleri

| Mülk | Değer | Birim |

|---|

| Brinell Sertliği (500 Kg yük) | 95 tipik | BHN |

| İşlenebilirlik Derecelendirmesi | 20 | – |

| Yoğunluk | 00,323 | 20 °C'de (68 °F) lb/in³ |

| Gerilme direnci | 40.000 | psi |

| Akma dayanımı | 20.000 | psi |

| Uzama | 20 | % |

| Esneklik Modülü | 15 | x 10^6 psi |

Farklı Sıcaklıklarda Performans

| Sıcaklık Aralığı | Performans Özellikleri | Önerilen Kullanım |

|---|

| Düşük Sıcaklık (-50°C ila 0°C) | Sünekliği ve tokluğu korur | Uygun |

| Oda Sıcaklığı (20°C ila 25°C) | Optimum güç ve aşınma direnci | İdeal |

| Yüksek Sıcaklık (100°C ila 200°C) | Gücünü korur ancak hafif yumuşama yaşayabilir | Kabul edilebilir |

| High Temperature (>200°C) | Uzun süreli kullanım için önerilmez | Tavsiye edilmez |

Endüstri Uygulamaları

| Endüstri | Uygulamalar | Temel Faydalar |

|---|

| Endüstriyel Makineler | Rulmanlar, dişliler, miller, sonsuz dişliler | Yüksek aşınma direnci |

| Deniz | Pompa çarkları, valf gövdeleri | Korozyon direnci |

| Yapı | Hareketli köprü bileşenleri, köprüler için döner tablalar | Güç ve dayanıklılık |

| Otomotiv | Piston segmanları | Düşük sürtünme katsayısı |

| Enerji | Buhar bağlantı parçaları | Isı direnci |

| madencilik | Ağır hizmet burçları | Darbe dayanımı |

| Havacılık | İniş takımları için burçlar | Yüksek yük kapasitesi |

| Yağ ve gaz | Valf bileşenleri | Zorlu ortamlarda korozyon direnci |

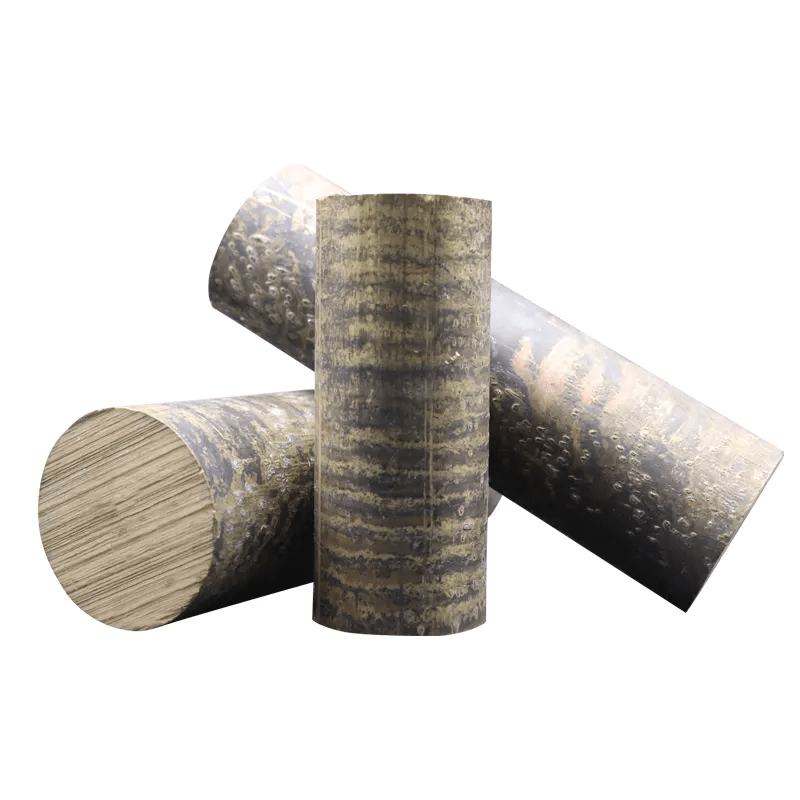

Şekil ve Boyut Kullanılabilirliği

| Şekil | Boyut aralığı | Standart Uzunluk |

|---|

| Katılar | 1 "ila 6" dış çap | 144" |

| Tüpler | 1 "ila 6" dış çap | 144" |

| Dikdörtgenler | 10″'e kadar | 144" |

| Tabaklar | 24″ kalınlığa kadar | 96" x 240" |

| Çubuklar | 00,25" ila 12" çap | 144" |

| Özel Şekiller | İhtiyaca göre | Değişir |

Mevcut Formlar

| Biçim | Tipik Kullanım | Kullanılabilirlik |

|---|

| Yarı mamul | Daha fazla işlem | Yaygın |

| Değirmen stoğu | Doğrudan kullanım | Yaygın olarak mevcuttur |

| Net'e yakın şekiller | Minimum işleme | Talep üzerine |

| Çubuk stoğu | İşleme | Standart |

| Plaka | Büyük düz bileşenler | Yaygın |

| Profil veya yapısal şekil | Özel uygulamalar | Talep üzerine |

| Dövmeler | Yüksek mukavemetli bileşenler | Sınırlı |

| Dökümler | Karmaşık şekiller | Yaygın |

Üretim Standartları ve Uyumluluk

| Standart/Uyumluluk | Bölge | Alaka düzeyi |

|---|

| Federal Güvenli İçme Suyu Yasası – SDWA | Amerika Birleşik Devletleri | Su güvenliği |

| S. 3874 Federal İçme Suyunda Kurşunun Azaltılması Yasası | Amerika Birleşik Devletleri | Potansiyel müşteri içeriği |

| Kaliforniya AB1953 | Kaliforniya, ABD | Potansiyel müşteri içeriği |

| Vermont Yasası 193 | Vermont, ABD | Potansiyel müşteri içeriği |

| ASTM B505 | Uluslararası | Bakır Alaşımlarının Sürekli Dökümü |

| ASTM B271 | Uluslararası | Bakır Bazlı Alaşımlı Santrifüj Dökümler |

| ISO 1338 | Uluslararası | Dökme bakır alaşımları |

| HE H5111 | Japonya | Bronz dökümler |

Farklı Ülkelerdeki Standartlar ve Karşılık Gelen Sınıflar

| Ülke | Standart | İlgili Sınıf |

|---|

| Amerika Birleşik Devletleri | BİZ | C90810 |

| Almanya | İTİBAREN | CuSn12 |

| Japonya | O | CAC704 |

| Birleşik Krallık | BS | HTB1 |

| Fransa | NF | CuSn12 |

| İtalya | ÜNİ | CuSn12 |

| Rusya | GOST | Bro12 |

| Çin | Büyük Britanya | ZCuSn12 |

| Uluslararası | ISO | CuSn12 |

Kaynak Özellikleri

| Kaynak Yöntemi | Uygunluk | Notlar | Ön Isıtma Sıcaklığı |

|---|

| Gaz Kaynağı | İyi | Fosfor bronz dolgu çubuğu kullanın | 150-200°C |

| TIG Kaynağı | Harika | Saf argon koruyucu gaz kullanın | Gerektiğinde |

| MIG Kaynağı | İyi | Bronz dolgu teli kullanın | Gerektiğinde |

| Örtülü Kaynak | Adil | Bronz elektrotlar kullanın | Gerektiğinde |

| Direnç Kaynağı | Fakir | Tavsiye edilmez | Yok |

| Elektron Işın Kaynağı | İyi | Hassas uygulamalar için | Gerektiğinde |

| Lazer Kaynak | Adil | Dikkatli kontrol gerektirir | Gerektiğinde |

İşleme Özellikleri

| İşlem | Uygunluk | Notlar | Önemli Husus |

|---|

| İşleme | İyi | İşlenebilirlik derecesi 20 | Takım seçimi |

| Şekillendirme | Adil | Yüksek kalay içeriği nedeniyle sınırlı şekillendirilebilirlik | Aşırı deformasyondan kaçının |

| Dövme | Fakir | Tavsiye edilmez | Yok |

| Döküm | Harika | Kum ve santrifüj döküm için ideal | Uygun soğutma hızı |

| Ekstrüzyon | Fakir | Tipik olarak ekstrüzyona tabi tutulmaz | Yok |

| Derin Çekme | Fakir | Sınırlı süneklik | Tavsiye edilmez |

| Eğirme | Adil | Doğru tekniklerle mümkün | İş sertleşmesinden kaçının |

| Broşlama | İyi | Hassas boyutlandırmaya uygundur | Takım aşınması |

Parlatma Özellikleri

| Parlatma Yöntemi | Sonuç | Önerilen Aşındırıcılar |

|---|

| Mekanik Parlatma | İyi yüzey kalitesi elde edilebilir | Alümina veya elmas bileşikleri |

| Kimyasal Parlatma | Orta sonuçlar | Tescilli çözümler |

| Elektro-parlatma | Yüksek parlaklıkta kaplama için mükemmel | Fosforik asit bazlı elektrolitler |

| Parlatma | Yüksek parlaklık mümkün | İnce aşındırıcılı yumuşak kumaş tekerlekler |

| Alıştırma | Hassas kaplama | Elmas veya silisyum karbür bileşikleri |

| Honlama | Silindirik yüzeyler için iyi | Yapıştırılmış aşındırıcı taşlar |

Isı tedavisi

| Isı tedavisi | Sıcaklık Aralığı | Amaç | Soğutma Yöntemi |

|---|

| Tavlama | 550-650°C | Stres giderme ve yumuşatma | Yavaş soğutma |

| Çözüm Tedavisi | Uygulanamaz | C90810 ısıl işleme tabi tutulamaz | Yok |

| Yaş Sertleştirme | Uygulanamaz | C90810 yaşlandıkça sertleşemez | Yok |

| Stress giderici | 260-370°C | İç gerilimleri azaltın | Hava soğutma |

| Normalleştirme | Genellikle gerçekleştirilmez | Yok | Yok |

| Söndürme | Tavsiye edilmez | Distorsiyona neden olabilir | Yok |

Soğuk İşleme Özellikleri

| İşlem | Uygunluk | Notlar | Alternatif Öneri |

|---|

| Soğuk çalışma | Sınırlı | Yüksek kalay içeriği sünekliği azaltır | Gerekirse sıcak çalışmayı düşünün |

| Soğuk Çekme | Fakir | Tavsiye edilmez | Bunun yerine işlemeyi kullanın |

| Soğuk Haddeleme | Fakir | Tavsiye edilmez | Dökme veya işlenmiş formları göz önünde bulundurun |

| Soğuk Başlık | Uygun değil | Çok kırılgan | İşleme veya döküm kullanın |

| Soğuk dövme | Uygun değil | Gerekli süneklikten yoksun | Sıcak dövme veya döküm yapmayı düşünün |

| Bilyalı Dövme | Adil | Yüzey özelliklerini iyileştirebilir | Dikkatli kullanın |

C90810'un Avantajları ve Dezavantajları

| Avantajları | Dezavantajları | Hususlar |

|---|

| Yüksek güç | Sınırlı şekillendirilebilirlik | Minimal şekillendirme için tasarım |

| Mükemmel aşınma direnci | Bazı bronzlarla karşılaştırıldığında daha yüksek maliyet | Kritik uygulamaları düşünün |

| İyi korozyon direnci | Yüksek hızlı uygulamalar için uygun değildir | Düşük ila orta hız ayarlarında kullanın |

| Düşük sürtünme katsayısı | Sınırlı soğuk çalışma yeteneği | Döküm veya işlenmiş formlar için tasarım |

| Ağır yükler için uygundur | Isıl işlem uygulanamaz | Isıl işlem gerektirmeyen uygulamalar için seçin |

| İyi işlenebilirlik | Nispeten yüksek yoğunluk | Tasarımda ağırlığı göz önünde bulundurun |

| Mükemmel yataklama özellikleri | Çok düşük sıcaklıklarda kalay zararlılarına karşı hassastır | 13°C'nin altındaki sıcaklıklara uzun süre maruz kalmaktan kaçının |

| İyi boyutsal kararlılık | Kaynak yapmak zor olabilir | Uygun kaynak tekniklerini kullanın |

| Deniz suyu korozyonuna dayanıklı | Çelik kadar güçlü değil | Uygun yük koşullarında kullanın |

| Düşük manyetik geçirgenlik | Pirinçten daha yüksek maliyet | Maliyeti performans gereksinimleriyle gerekçelendirin |

Benzer Ürünler

| Alaşım | UNS Numarası | Ana Kompozisyon | Temel Farklılıklar |

|---|

| C90700 | C90700 | Cu-Sn-Zn | Daha düşük kalay, daha yüksek çinko içeriği |

| C91100 | C91100 | Sn ile | Daha yüksek kalay içeriği, kurşun yok |

| C93200 | C93200 | Cu-Sn-Pb | Geliştirilmiş işlenebilirlik için daha yüksek kurşun içeriği |

| C95400 | C95400 | Cu-Al-Fe | Farklı özellik profiline sahip alüminyum bronz |

| C95500 | C95500 | Cu-Al-Ni-Fe | Daha yüksek mukavemete sahip nikel-alüminyum bronz |

| C86300 | C86300 | Cu-Mn-Ni-Fe | Daha yüksek mukavemetli manganez bronz |

| C92200 | C92200 | Cu-Sn-Pb-Zn | Farklı bileşime sahip Navy M gun metal |

C90810'un Benzer Ürünlerle Karşılaştırılması

| Mülk | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| Çekme Dayanımı (psi) | 40.000 | 36.000 | 45.000 | 35.000 | 90.000 |

| Akma Dayanımı (psi) | 20.000 | 18.000 | 25.000 | 18.000 | 45.000 |

| Uzama (%) | 20 | 25 | 15 | 20 | 15 |

| Brinell Sertliği | 95 | 70 | 100 | 65 | 190 |

| Korozyon Direnci | Harika | İyi | Harika | İyi | Harika |

| İşlenebilirlik | İyi | Çok güzel | Adil | Harika | Adil |

| Kaynaklanabilirlik | Adil | İyi | Adil | Fakir | İyi |

| Aşınma direnci | Harika | İyi | Harika | İyi | Harika |

| Maliyet | Yüksek | Ilıman | Çok Yüksek | Ilıman | Yüksek |

| tipik uygulamalar | Ağır hizmet tipi rulmanlar | Genel amaçlı | Yüksek yüklü rulmanlar | Burçlar, rulmanlar | Denizcilik bileşenleri |

Çözüm:

C90810 Yüksek Kalaylı Bronz, özelliklerin benzersiz bir kombinasyonunu sunan, onu çeşitli endüstriyel uygulamalarda paha biçilmez kılan özel bir alaşımdır. Yüksek kalay içeriği, özellikle ağır yük ve düşük hız ayarlarında mükemmel dayanıma, aşınma direncine ve korozyon direncine katkıda bulunur. Şekillendirilebilirlik ve yüksek sıcaklık uygulamalarında sınırlamalara sahip olsa da C90810, denizcilik mühendisliği, endüstriyel makineler ve inşaat gibi endüstrilerde üstünlük sağlar.

Alaşımın çok yönlülüğü, mevcut geniş form ve boyut yelpazesinde, uluslararası standartlara uygunluğunda ve iyi işlenebilirliğinde açıkça görülmektedir. Ancak tasarımcılar ve mühendisler, C90810'u projelerine dahil ederken sınırlı soğuk çalışma yeteneği ve ısıl işlem seçenekleri gibi spesifik özelliklerini dikkate almalıdır.

Benzer alaşımlarla karşılaştırıldığında C90810, güç dengesi, aşınma direnci ve korozyon direnciyle öne çıkıyor. Benzersiz özellik profili, bu özelliklerin çok önemli olduğu uygulamalar için onu ideal bir seçim haline getiriyor ve kritik bileşenlerdeki yüksek maliyetini haklı çıkarıyor.

Özetle, C90810 Yüksek Kalay Bronz, diğer alaşımların yetersiz kalabileceği zorlu ortamlarda güvenilir performans sunarak modern mühendislikte değerli bir malzeme olmaya devam ediyor.