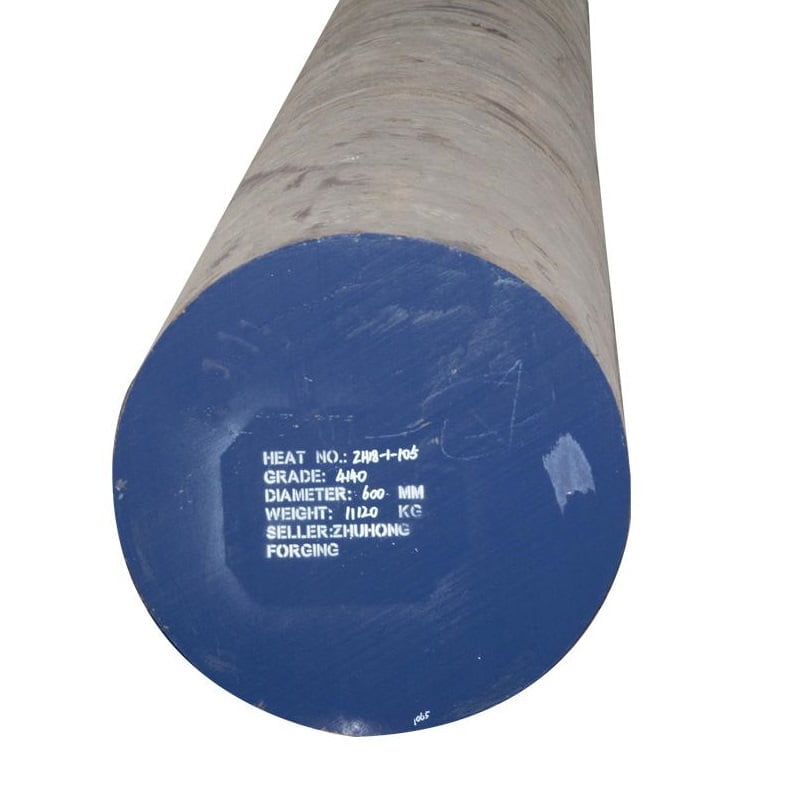

Steel is a ubiquitous material in modern engineering, valued for its strength, durability, and versatility. Among the myriad types of steel available, 42CrMo4 stands out for its specific composition and exceptional mechanical properties. This article delves into the performance characteristics and diverse applications of 42CrMo4 round steel, highlighting its significance in various industries.

Chemical Composition and Properties

42CrMo4 is a chromium-molybdenum alloy steel that contains chromium and molybdenum as strengthening agents. Its chemical composition typically includes 0.38-0.45% carbon, 0.60-0.90% manganese, 0.90-1.20% chromium, 0.15-0.30% molybdenum, and 0.10-0.25% silicon. These elements contribute to its high tensile strength, good toughness, and excellent wear resistance.

The steel is renowned for its ability to withstand high static and dynamic loads, making it suitable for heavy-duty machinery components subjected to varying stresses. Its heat treatment capabilities further enhance its mechanical properties, offering improved hardness and toughness.

Mechanical Properties

Mechanical properties of 42CrMo4 steel are tailored through heat treatment processes such as quenching and tempering. In its hardened and tempered condition, it exhibits a tensile strength of 900-1100 MPa and a yield strength of 650 MPa, along with good elongation and impact strength. These attributes make it ideal for applications requiring high strength combined with good ductility, such as gears, crankshafts, and heavy-duty axles.

Applications

The versatility of 42CrMo4 round steel extends across various industries:

- Automotive and Aerospace: In automotive engineering, 42CrMo4 is used for critical components like axle shafts, steering knuckles, and gears due to its high fatigue strength and impact resistance. In aerospace, it finds application in structural parts where lightweight strength is essential.

- Engineering Machinery: The steel is employed in manufacturing machinery components such as hydraulic cylinders, piston rods, and connecting rods, where high strength and durability are prerequisites.

- Energy Sector: Components in the energy sector, including turbine shafts, generator shafts, and rotor bolts, benefit from 42CrMo4’s ability to withstand high rotational speeds and heavy loads.

- Toolmaking: Due to its hardenability and wear resistance, 42CrMo4 is utilized in making molds, dies, and cutting tools where durability and precision are critical.

- Construction and Mining: Equipment in construction and mining industries, such as crane shafts, drill rods, and excavator pins, rely on the toughness and abrasion resistance of 42CrMo4 steel.

Processing and Machinability

While 42CrMo4 steel offers excellent mechanical properties, its machinability can vary depending on its condition. In its annealed state, it can be machined relatively easily. However, in its hardened and tempered condition, machining becomes more challenging due to its high hardness. Carbide tools and appropriate cutting parameters are recommended for achieving optimal results.

Conclusion

42CrMo4 round steel stands as a testament to the advancements in metallurgical engineering, offering a blend of high strength, toughness, and wear resistance. Its chemical composition and heat treatability make it a preferred choice for critical components in automotive, aerospace, machinery, and energy sectors. Engineers and designers value its reliability in demanding applications where performance under stress is paramount.

As industries continue to evolve, the demand for robust materials like 42CrMo4 will persist, driving further research and innovation in steel manufacturing. Its role in shaping modern infrastructure and technology underscores its significance in the global economy. Whether in a factory or beneath the Earth’s surface, 42CrMo4 steel remains an indispensable material for building a resilient and efficient future.