Introduction

Galvanized steel has become an essential material in various industries thanks to its effective corrosion resistance and durability. It combines the strength of steel with the protective qualities of zinc coating, making it ideal for applications that demand longevity and resilience. In this article, we will explore the properties, production methods, applications, advantages, disadvantages, and future trends of galvanized steel, delving into its significance in modern construction and manufacturing.

Understanding Steel

Before we dive into the specifics of galvanized steel, it is essential to understand the properties of steel itself. Steel is an alloy primarily composed of iron and carbon, with carbon content typically between 0.2% and 2.1% by weight. Variations in the carbon content, along with the addition of other elements, lead to different types and grades of steel, each suited for specific applications.

Properties of Steel

Steel is renowned for its:

- Strength: It can withstand considerable loads and mechanical stress, making it ideal for structural applications.

- Ductility: Steel can be deformed into various shapes without fracturing, allowing for flexibility in design and fabrication.

- Weldability: Steel can be easily welded, enabling the creation of complex structures and components.

- Malleability: The ability of steel to be shaped under pressure adds to its versatility.

- Conductivity: Steel has good thermal and electrical conductivity, making it suitable for various engineering applications.

Despite its numerous advantages, steel is prone to corrosion, especially when exposed to moisture and harsh environmental conditions. This vulnerability is where galvanized steel comes into play.

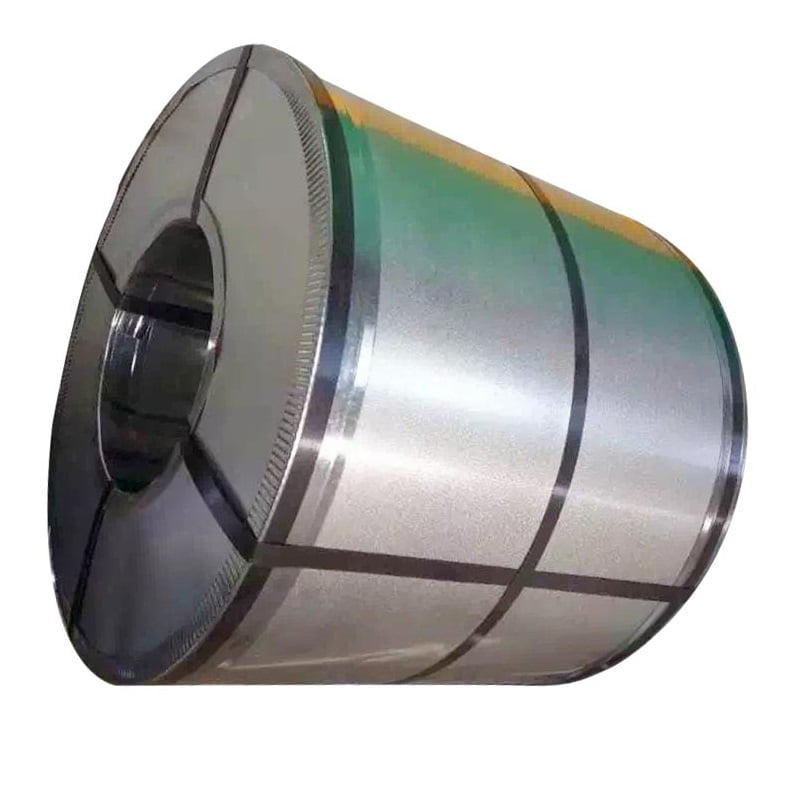

What is Galvanized Steel?

Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion. The zinc acts as a barrier between the steel and the environment, preventing moisture and oxygen from reaching the underlying metal. This protective coating significantly increases the lifespan of steel products, making them suitable for outdoor and industrial applications.

The Galvanization Process

The process of galvanization involves applying a layer of zinc to the surface of steel through several methods. The most common methods of galvanization include:

- Hot-Dip Galvanizing: In this method, steel is immersed in a bath of molten zinc at temperatures ranging from 450 to 460 degrees Celsius (842 to 860 degrees Fahrenheit). The heat causes the zinc to bond with the steel, forming a thick and durable coating. Hot-dip galvanizing is known for its robust protective properties and is widely used for large structural components.

- Electro-galvanizing: This method involves the application of a zinc coating through an electroplating process. In this process, steel is immersed in a solution containing zinc salts, and an electric current is passed through the solution, resulting in the deposition of zinc onto the steel surface. The zinc coating produced through electro-galvanizing tends to be thinner and more uniform than that obtained through hot-dip galvanizing.

- Zinc Spray Coating: This method involves the application of molten zinc onto the steel surface using a spray technique. Zinc spray coating is often used for repair and maintenance applications, providing a protective layer where the original galvanized coating may have worn away.

- Galvannealed Coating: In this process, steel is first hot-dip galvanized and then heated in a controlled atmosphere, allowing some of the zinc to react with the iron in the steel surface. This results in a coating that provides excellent paint adhesion and corrosion resistance.

Types of Galvanized Steel

Different types of galvanized steel are characterized by the thickness of the zinc coating, which is measured in grams per square meter (g/m²). The common types include:

- G30: This grade has a zinc coating of approximately 30 g/m² and is typically used for indoor applications where exposure to moisture is limited.

- G60: With a zinc coating of about 60 g/m², G60 galvanized steel is suitable for moderate outdoor exposure and is commonly used for roofing panels and siding.

- G90: This grade features a coating of approximately 90 g/m², making it suitable for harsher environments and applications such as fences, poles, and structural beams.

- Zinc-Aluminum Coating: Some galvanized steels are coated with a mixture of zinc and aluminum, providing enhanced corrosion resistance and heat reflectivity.

Properties of Galvanized Steel

The unique properties of galvanized steel make it an attractive choice for various applications. Key properties include:

Corrosion Resistance

The primary advantage of galvanized steel is its exceptional corrosion resistance. The zinc coating prevents exposure to moisture and oxygen, significantly reducing the risk of rust and corrosion. Even if the coating is scratched or damaged, the zinc will continue to protect the exposed areas through a process known as “cathodic protection.” Zinc acts as a sacrificial anode, corroding preferentially to the steel, and thus prolonging the lifespan of the underlying metal.

Durability

Galvanized steel exhibits high durability, making it suitable for both indoor and outdoor applications. It can withstand harsh environmental conditions, including rain, humidity, and temperature fluctuations. The combination of steel’s strength and zinc’s protective qualities results in a long-lasting material.

Cost-Effectiveness

While the initial cost of galvanized steel may be higher than that of uncoated steel, its long-term cost-effectiveness is undeniable. The extended lifespan and reduced maintenance requirements associated with galvanized steel make it a wise investment for industries and businesses.

Aesthetic Appeal

Galvanized steel has a distinctive appearance characterized by a glossy, metallic finish. This aesthetic appeal can enhance the overall look of a structure or product, making it suitable for applications in architecture and design.

Eco-Friendliness

Galvanized steel is recyclable, and its production process generates minimal waste. The use of zinc as a protective coating means that galvanized steel products can be reused and repurposed, contributing to a more sustainable environment.

Applications of Galvanized Steel

Galvanized steel is widely used in various industries due to its favorable properties. Some common applications include:

Construction

Galvanized steel is prevalent in the construction industry for the following applications:

- Structural Components: Beams, columns, and frames made from galvanized steel are used in building construction due to their strength and corrosion resistance.

- Roofing and Siding: Galvanized sheets are commonly used for roofing panels and siding materials, providing a protective barrier against moisture and weather elements.

- Fencing and Gates: Fences, gates, and railings made from galvanized steel are durable and resistant to rust, making them suitable for outdoor use.

Automotive Industry

Galvanized steel has significant applications in the automotive sector:

- Chassis and Body Panels: Galvanized steel is used for the production of vehicle chassis and body panels, providing protection against rust and corrosion, which can occur due to exposure to road salt and moisture.

- Exhaust Systems: Some components of exhaust systems are made from galvanized steel, as it offers high-temperature resistance and corrosion protection.

Appliance Manufacturing

Galvanized steel is commonly used in the manufacturing of household appliances:

- Refrigerators and Washers: The protective qualities of galvanized steel make it an excellent choice for refrigerator and washer casings, ensuring longevity and reliability.

- Cooking Equipment: Stoves and ovens often utilize galvanized steel for durability and resistance to heat and moisture.

Agricultural Equipment

In the agricultural sector, galvanized steel is used for:

- Fencing and Gates: Livestock fencing and gates made from galvanized steel are resistant to rust and wear, ensuring a long service life.

- Storage Tanks: Galvanized steel tanks are ideal for storing water, feed, and chemicals due to their resistance to corrosion.

Electrical Industry

Galvanized steel is also utilized in electrical applications:

- Conduits and Cable Trays: Galvanized steel conduits and cable trays provide protection for electrical wiring, ensuring safety and longevity.

- Lighting Fixtures: Many outdoor lighting fixtures use galvanized steel for enhanced durability in harsh weather conditions.

Advantages of Galvanized Steel

The use of galvanized steel comes with numerous advantages:

1. Long Lifespan

Galvanized steel has an extended service life, often lasting up to 50 years or more, depending on the environmental conditions and the thickness of the zinc coating. This longevity reduces the need for frequent replacements and maintenance, leading to cost savings over time.

2. Low Maintenance

The corrosion resistance of galvanized steel means that it requires minimal maintenance compared to uncoated steel. Regular inspections are sufficient, and repainting or re-coating is generally unnecessary, further reducing maintenance costs.

3. Versatility

Galvanized steel can be used in a wide range of applications across various industries, making it a versatile material choice.

4. Enhanced Safety

Galvanized steel minimizes the risk of structural failures due to corrosion, ensuring the safety and integrity of buildings, vehicles, and equipment.

5. Environmental Benefits

Being recyclable and having a long lifespan, galvanized steel contributes to sustainable practices in construction and manufacturing. The use of recycled materials in the production process reduces the carbon footprint associated with steel manufacturing.

Disadvantages of Galvanized Steel

Despite its numerous advantages, galvanized steel also has some drawbacks:

1. Initial Cost

The upfront cost of galvanized steel is often higher than that of uncoated steel. However, the long-term cost savings from reduced maintenance and extended service life typically justify this initial expense.

2. Limited High-Temperature Applications

The zinc coating of galvanized steel can begin to degrade at high temperatures, limiting its use in environments that experience extreme heat.

3. Difficulty in Welding

Welding galvanized steel can pose challenges due to the presence of the zinc coating. Proper precautions must be taken during welding to prevent zinc vapors, which can be harmful when inhaled.

4. Aesthetic Limitations

While galvanized steel has a unique appearance, some applications may require specific finishes or coatings for aesthetic purposes. Additional treatments may be necessary to achieve the desired look.

Future Trends in Galvanized Steel

As industries evolve and sustainability becomes more critical, several trends are emerging in the use of galvanized steel:

1. Increasing Demand for Sustainable Materials

The demand for eco-friendly building materials is on the rise. Galvanized steel’s recyclability and long lifespan position it favorably within the context of sustainable construction practices.

2. Advancements in Coating Technologies

Innovations in galvanization techniques, such as improved electro-galvanizing and zinc-aluminum coatings, will enhance the performance and durability of galvanized steel in various applications.

3. Smart Steel Applications

The integration of technology into steel products is gaining traction. As smart construction and manufacturing become more prevalent, galvanized steel may incorporate sensors and smart features to monitor structural integrity and environmental conditions.

4. Expanding Applications

As industries seek innovative solutions for corrosion prevention, the applications of galvanized steel are expected to expand further. New markets may arise, particularly in renewable energy, transportation, and smart infrastructure.

Conclusion

Galvanized steel is a remarkable material that combines the strength of steel with the protective qualities of zinc. Its unique properties, including exceptional corrosion resistance, durability, and low maintenance, have made it a popular choice across various industries, from construction to automotive manufacturing. While it has some disadvantages, their impact is often mitigated by the long-term benefits of using galvanized steel.

As industries continue to seek sustainable and innovative solutions, galvanized steel is likely to remain a vital component in modern construction and manufacturing, contributing to the efficiency and longevity of products and structures. With ongoing advancements in coating technologies and an increasing focus on eco-friendliness, galvanized steel is poised to play an even more significant role in the future of materials engineering.