Introduction

DX51D is a widely recognized designation for hot-dip galvanized steel made according to the European standard EN 10346. This type of steel is favored across various industries for its remarkable balance of durability, corrosion resistance, and formability. It plays a crucial role in numerous applications, particularly in construction, automotive, and manufacturing sectors. This document will provide a comprehensive overview of DX51D, its properties, applications, equivalent grades, and advantages and disadvantages, extending to comprehensive insights that will encompass approximately 2000 words.

What is DX51D?

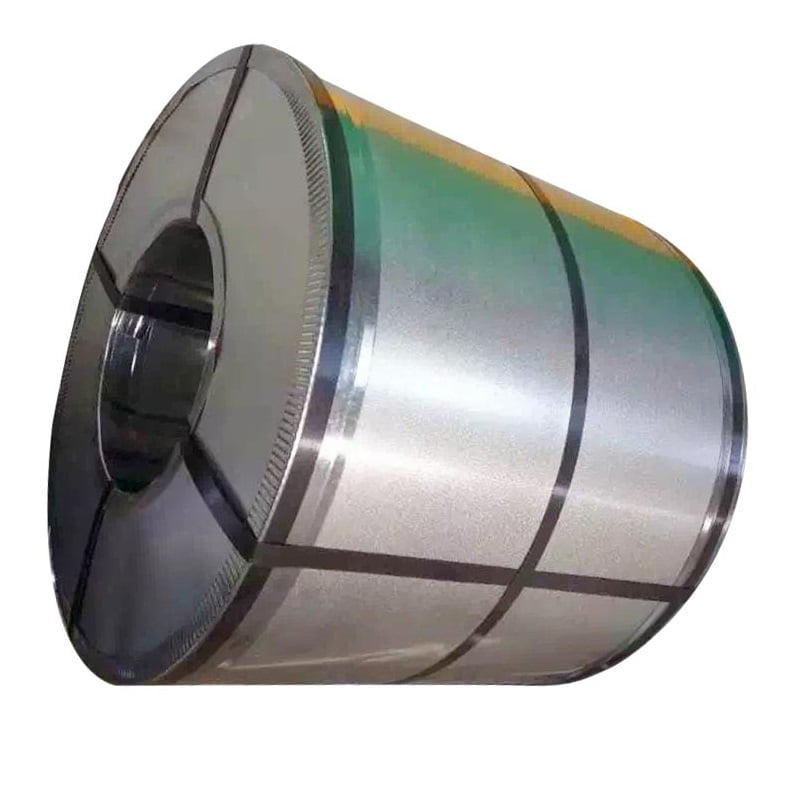

DX51D steel is primarily characterized by its hot-dip galvanization process. In essence, hot-dip galvanizing involves immersing steel in molten zinc, creating a thick, protective layer that guards against corrosion. This designation falls under the European standard for coated steel sheets and strips for cold forming.

Key Characteristics of DX51D

- Corrosion Resistance: One of the most significant attributes of DX51D is its ability to resist corrosion. The zinc coating serves as a barrier, preventing moisture and environmental factors from compromising the integrity of the underlying steel.

- Mechanical Properties: DX51D typically has a minimum yield strength of around 250 MPa, with a tensile strength ranging from 330 MPa to 450 MPa, depending on the specific thickness and coating weight.

- Formability: DX51D exhibits excellent formability, making it suitable for various applications that require bending, stamping, or other metalworking processes.

- Surface Finish: This grade of steel is known for its smooth surface finish, often preferred in applications where aesthetics matter.

Chemical Composition

The chemical composition of DX51D consists mostly of iron, complemented by zinc and other alloying elements. While the exact composition can vary depending on the specific manufacturing processes, typical values include:

| Element | Percentage (%) |

|---|---|

| Iron (Fe) | Balance |

| Zinc (Zn) | < 0.21% |

| Carbon (C) | < 0.12% |

| Manganese (Mn) | < 0.60% |

| Phosphorus (P) | < 0.04% |

| Sulfur (S) | < 0.05% |

Maintaining the correct chemical composition is vital for ensuring that DX51D meets its required specifications for strength, corrosion resistance, and formability.

Applications of DX51D Steel

DX51D steel is employed across various industries and applications due to its favorable properties. Here are some common applications:

1. Construction

DX51D is extensively used in the construction industry. Its corrosion resistance makes it ideal for:

- Roofing Panels: Durable roofing materials that can withstand the elements.

- Wall Cladding: Aesthetic and protective wall coverings for buildings.

- Structural Frameworks: Used in building frames where strength and longevity are critical.

2. Automotive Industry

The automotive sector relies on DX51D steel for several components due to its strength and lightweight nature. Applications include:

- Body Panels: The outer body of vehicles often uses DX51D for its corrosion resistance and impact strength.

- Chassis Components: The framework of vehicles benefits from the strength-to-weight ratio offered by this steel grade.

- Interior Parts: Certain interior components that require durability and aesthetic appeal can be made from DX51D.

3. Manufacturing

In manufacturing, DX51D finds a place in various products, such as:

- Home Appliances: Components of refrigerators, washing machines, and other appliances.

- Furniture: The frames of tables, chairs, and shelving units can utilize DX51D due to its strength and durability.

- Industrial Equipment: Machinery and equipment parts in harsh environments where corrosion resistance is essential.

Equivalent Grades of DX51D

Understanding the equivalents to DX51D helps manufacturers and engineers identify alternative materials for specific applications. Below are well-known grades equivalent to DX51D steel:

| Standard | Equivalent Grade | Description |

|---|---|---|

| EN 10346 | DX51D | Hot-dip galvanized steel tailored for cold forming. |

| ASTM A653 | G90 | An American equivalent with a minimum coating weight of 90 g/m². |

| JIS G3302 | SGCC | Japanese standard for galvanizing with general applications. |

| ISO 3574 | SPCC | Cold-rolled carbon steel sheet for further processing. |

| BS EN 10327 | S250GD | Hot-dip galvanized steel for cold forming applications. |

Identifying the appropriate equivalent grades is crucial for ensuring the right material properties and performance in specific applications.

Advantages of DX51D Steel

The choice of DX51D steel benefits industries in various ways:

1. Excellent Corrosion Resistance

The galvanization of DX51D provides a robust defense against rust and deterioration. This characteristic is particularly vital in outdoor environments or locations exposed to humidity or chemicals.

2. High Strength-to-Weight Ratio

With a minimum yield strength of approximately 250 MPa, DX51D offers significant strength without excessive weight, making it suitable for applications requiring both strength and lightness.

3. Cost-Effectiveness

Though the initial cost of DX51D may be higher than non-galvanized alternatives, its longevity and reduced maintenance requirements often lead to lower overall costs in the long run.

4. Aesthetic Appeal

The smooth and shiny surface finish of DX51D steel also makes it visually appealing, making it a preferred choice for applications where appearance matters.

5. Versatility in Applications

DX51D can be used in various processes such as stamping, bending, and roll forming, making it a versatile choice across multiple industries.

Disadvantages of DX51D Steel

While DX51D has many advantages, there are also some drawbacks to consider:

| Disadvantage | Description |

|---|---|

| Initial Cost | Higher upfront costs compared to non-galvanized steel. |

| Limited High-Temperature Performance | May lose some of its properties at extremely high temperatures. |

| Welding Challenges | The zinc coating can pose difficulties in welding and may require specific techniques to avoid toxicity from zinc fumes. |

| Conformity to Standards | Compliance with specific standards may vary across manufacturers, so it is crucial to verify material properties. |

Example of Disadvantages Affecting Applications

- Welding Limitations: When fabricating components that require extensive welding, care must be taken to either remove or manage the zinc coating, which can produce harmful fumes if not handled properly.

- Cost Implications: In projects where budget constraints are stringent, the higher initial cost of using DX51D may require careful justification based on the expected longevity and durability.

Future Trends and Developments

As industries continue to evolve, so do the materials used in construction, automotive, and manufacturing. Several trends impacting DX51D can be observed:

1. Growing Demand for Sustainable Materials

As the world focuses more on sustainable practices, the need for materials that are recyclable and have lower environmental impact is increasing. DX51D, with its zinc coating, can be recycled and used in other products.

2. Development of Advanced Coatings

Ongoing research into advanced coatings may enhance the properties of DX51D, such as improving its performance in high-temperature environments or further increasing corrosion resistance by experimenting with different alloying elements.

3. Smart Steel Technologies

Incorporating technology into steel production and applications may lead to the development of smart materials that can monitor their own structural status, helping to predict failures before they occur.

4. Expansion in Application Areas

As DX51D continues to prove itself in current applications, new usage possibilities may arise, especially in renewable energy sectors like wind and solar, where durable and corrosion-resistant materials are a necessity.

5. Customization of Materials

The trend towards customized materials that suit specific applications demands flexibility in production processes, encouraging manufacturers to explore new ways of meeting client needs concerning thickness, mechanical properties, and coating weights.

Conclusion

DX51D steel is a crucial material that exemplifies the balance between durability, corrosion resistance, and formability. Its widespread use across various industries without sacrificing performance demonstrates the importance of selecting the right material for specific applications. While the initial costs may be higher than alternatives, the long-term advantages often justify the investment.

Incorporating a comprehensive understanding of equivalent grades, applications, advantages, disadvantages, and future trends enables engineers and manufacturers to make informed decisions. Whether in construction, automotive manufacturing, or various types of industrial applications, DX51D and its properties will continue to play a pivotal role in advancing modern infrastructure and manufacturing processes.

As we look into the future, embracing innovations and sustainability will enhance the performance of DX51D while addressing the demands and challenges of new industrial landscapes. This will further solidify DX51D’s position as a reliable choice in materials engineering.