O aço para matrizes para trabalho a frio e o aço para matrizes para trabalho a quente são diferenciados principalmente pelas condições sob as quais são usados e suas propriedades: Condições de uso: Temperaturas de operação: Propriedades: Elementos de liga: Em resumo, a principal diferença está nas condições de temperatura sob as quais esses aços são usados e suas respectivas propriedades otimizadas para essas condições. Escolhendo...

SKD61 e SKD6 são tipos de aços de ferramentas de trabalho quentes, mas diferem em suas composições e propriedades, o que os torna adequados para diferentes aplicações. SKD61 (H13): SKD6 (H11): Diferenças -chave: Em resumo, enquanto o SKD61 (H13) e o SKD6 (H11) são aços de ferramentas de trabalho quentes, suas diferenças de composição e propriedades resultantes os tornam ...

O aço P20 e o aço 4140 são materiais populares na área de fabricação industrial e ferramentas, mas servem a propósitos diferentes devido às suas propriedades distintas. Aço P20: Aço 4140: Comparação: Em resumo, a escolha entre o aço P20 e o aço 4140 depende dos requisitos específicos da sua aplicação. O aço P20 é ideal para...

O aço do molde CR12MOV possui boa hardenabilidade, hardenabilidade, resistência ao desgaste, resistência e resistência, estabilidade térmica ... No entanto, às vezes devido a alguns motivos, as rachaduras em aço do molde CR12MOV após o tratamento térmico. Então, por que ...

M2 Aço de alta velocidade M2 A aço de ferramentas de alta velocidade nasceu em 1937. Devido ao seu excelente desempenho e preço adequado, ainda é o aço de alta velocidade mais amplamente utilizado. É frequentemente usado no processamento da super-alojamento aeroespacial, aço de força ultra-alta e aço inoxidável e outros materiais difíceis de trabalhar. Um grande ...

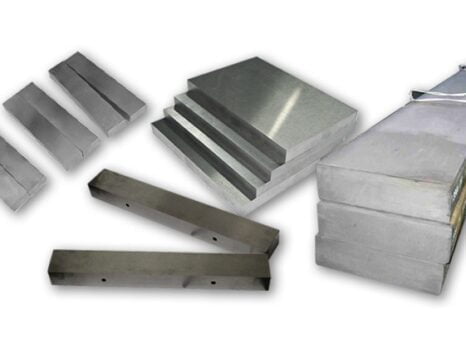

Tabela de comparação de grau de aço do molde mundial para facilitar os clientes para escolher e encomendar materiais de aço de molde com mais rapidez e precisão, o Departamento de Tecnologia de Metal de Lion editou especialmente este artigo para listar as notas comumente usadas de aço mofo em casa e no exterior. Seu conteúdo envolve o American Finn Cola, a Suécia Assab, o Japão, Datong, Hitachi do Japão, Japão ...