42CrMo4 Description

42CrMo4 steel belongs to ultra-high strength steel, which has high strength and toughness, good hardenability, no obvious tempering brittleness, high fatigue limit and multiple impact resistance ability after tempering and tempering treatment, and good impact toughness at low temperature.

42CrMo4 steel is suitable for large and medium sized plastic molds which require certain strength and toughness.

Grade: 42CrMo4

Execution Standard: EN 10083/3-2006

Features: High strength, hardenability, good toughness

Advantages: Good machinability, easy polishing, easy to bite

Type: Industrial materials

Function: big gear for locomotive traction, turbocharger transmission gear, rear axle, etc

42CrMo4 Material Introduction

42CrMo4 is an industrial material.Is used to manufacture forgings with higher strength and larger cross-section than 35CrMo steel, such as big gear for locomotive traction, turbocharger transmission gear, rear shaft, connecting rod and spring clamp with great load.

42CrMo4 can also be used for drilling pipe joints and fishing tools in deep oil Wells below 2000m.

Executive standard :EN 10083/3-2006

42CrMo4 Characteristics:

Has high strength, hardenability, good toughness, small deformation during quenching, high creep strength and endurance strength at high temperature.

42CrMo4 steel is an improvement of American AISI standard 4140 steel. The steel has good machinability, easy polishing, easy to bite and can be electroplated.

42CrMo4 alloy steel(Bar,Plate,Square) is suitable for large and medium sized plastic molds which require certain strength and toughness.

42CrMo4 Alloy Steel Chemical Composition

| 42CrMo4/1.7225 | C | Mn | Si | P | S | Cr | Mo |

| 0.38-0.45 | 0.60-0.90 | 0.40 max | 0.035 max | 0.035 max | 0.90-1.20 | 0.15-0.30 |

DIN 42CrMo4 Alloy Steel Mechanical Properties

| Size Ø mm | Yield stress Rp0.2,N/nn2, min. | Ultimate tensile Stress, Rm,N/nn2 | Elongation A5,%, min. | Hardness HB | Toughness KV, Joule, min. | ||||||||||

| <40 | 750 | 1000-1200 | 11 | 295-355 | 35 at 20ºC | ||||||||||

| 40-95 | 650 | 900-1100 | 12 | 265-325 | 35 at 20ºC | ||||||||||

| >95 | 550 | 800-950 | 13 | 235-295 | 35 at 20ºC | ||||||||||

BS EN 42CrMo4 Alloy Steel Relevant Specifications and Equivalents

| BS EN 10250 | Material No. | DIN | ASTM A29 | JIS G4105 | BS 970-3-1991 | BS 970-1955 | AS 1444 | AFNOR |

| 42CrMo4 | 1.7225 | 38HM | 4140 | SCM440 | 708M40 | EN19A | 4140 | 42CD4 |

42CrMo4 Heat treatment recommendations

| Treatment | Condition | Temperature cycle | Cooling/quenching |

|---|---|---|---|

| Hot forging | +U | 850-1050°C | In air |

| Soft annealing | +A | 680-720°C | Slowly ( 15°C/h) until 600°C |

| Stress relieve annealing | +SRA | 450-650°C | In air |

| Quench & Tempering | +QT | 840-880°C | In oil or water. Temper in 540-680°C |

| Stress relieve annealing | +SRA | 150-180°C ( after Induction Hardening ) | In air |

Weldability

Engineering steel 42CrMo4 has only limited weldability. Preheating to 200-300°C is strongly recommended; the upper limit should not be exceeded because of risk for deterioration of the chrome layer.

Can be friction welded. However, precautions are necessary so as to limit the formation of undesirable microstructures in the welded zone.

Supply Range

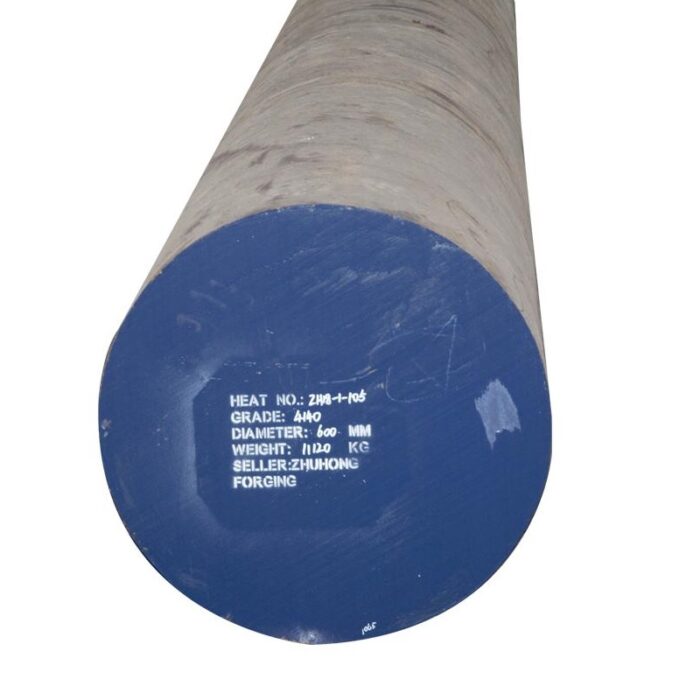

Round bar Sizes: 10mm – 3000mm

Flat and Plate: 10mm-1500mm thickness x 200-3000mm width

Other steel shape and sizes available according to your requirements.

| Youngs module (GPa) | Poisson´s ratio (-) | Shear module (GPa) | Density (kg/m3) |

|---|---|---|---|

| 210 | 0.3 | 80 | 7800 |

| Average CTE 20-300°C (µm/m°K) | Specific heat capacity 50/100°C (J/kg°K) | Thermal conductivity Ambient temperature (W/m°K) | Electrical resistivityAmbient temperature (µΩm) |

| 12 | 460 – 480 | 40 – 45 | 0.20 – 0.25 |

Testing and packaging

Testing and packaging are considered one of the most critical steps of the manufacturing process.

We do several tests and inspections to check the quality of 42CrMo4 steel round bar. Tests done depend on the requirement of the users. Those quality tests can include chemical composition test, physical test, visual inspection, macro and micro test, NDT test and ultrasonic test depending on the requirement of the customers. We can also arrange third-party inspection if required. A test certificate is given for each consignment for the tests conducted.

At last, we bundle or pack the 42CrMo4 round bar to prevent damage at the time of transportation.