Introduction to 12L14 Free Cutting Steel:

12L14 is free cutting structural steel, free cutting steel is easy to be (turning, milling, drawing, planing, drilling, etc.) cutting steel. 12L14 also known as automatic machine tool processing steel, automatic steel for short. 12L14 is to adapt to the mechanical processing automation and production line.

Grade:12L14 Type:Free cutting structural steels Mechanical properties: Tensile Strength σb (MPa):540 Hardness: 100-150 HBW Section shrinkage ψ(%) : 35-60 Elongation Δ5 (%) : 20-40

Introduction to 12L14 Free Cutting Steel:

12L14 is free cutting structural steel, free cutting steel is easy to be (turning, milling, drawing, planing, drilling, etc.) cutting steel, also known as automatic machine tool processing steel, automatic steel for short.It is to adapt to the mechanical processing automation and assembly line production.This kind of steel can use high cutting speed and deep turning machining, and since joining the free-cutting steel elements make cutting resistance decreases and the join of the element itself characteristics and formation of the compound ACTS as lubricate cutter blade, make the chip easy broken, reduce the wear and tear, thus improve the roughness and precision of the processed parts, improves the knives’ service life and production efficiency.

12L14 Steel Main Uses

Mainly used for making small force and strict requirements on size and finish of instruments and meters, watch parts, automobiles, machine tools and other machines used in strict requirements on size accuracy and finish, but relatively low requirements on mechanical properties of standard parts,Such as gears, shafts, bolts, valves, bushings, pins, pipe joints, spring seat and machine tool screws, plastic molding molds, surgical and dental tools, etc.

12L14 Free Cutting Steel Chemical Component

C:<= 0.15 Mn:0.85~1.15 S:0.26~0.35 P:0.04~0.09 Pb:0.15~0.35

12L14 Free Cutting Steel Mechanical Property

Tensile strength σb (MPa) : 380-460

Yield strength σs (MPa) : –

Elongation Δ5 (%) : 20-40

Section shrinkage ψ(%) : 35-60

Hardness: 100-150 HBW

12L14 Free Cutting Steel Introduction

12L14 is free cutting structural steel, free cutting steel is easy to be (turning, milling, drawing, planing, drilling, etc.) cutting steel, also known as automatic machine tool processing steel, automatic steel for short.It is to adapt to the mechanical processing automation and assembly line production.This kind of steel can use high cutting speed and deep turning machining, and since joining the free-cutting steel elements make cutting resistance decreases and the join of the element itself characteristics and formation of the compound ACTS as lubricate cutter blade, make the chip easy broken, reduce the wear and tear, thus improve the roughness and precision of the processed parts, improves the knives’ service life and production efficiency.12L14 belongs to lead-sulfur compound free cutting structural steel.In the cutting process, there is a strong friction between the tool and the workpiece, so that the lead particles in the steel are molten out, thus playing a role in lubrication to improve the cutting performance of steel, so that the steel chip is fine, reduce tool wear, and ultimately extend the life of the tool.Compared with steels without lead, the machinability of steels with lead can be improved by 20 ~ 50%, while the mechanical properties and heat treatment properties remain almost the same, and there is no influence on the cold and hot workability and weldability.Lead free cutting steel has been widely used in the manufacture of precision instrument parts, automobile parts, and important parts of all kinds of machinery.However, lead free cutting steel has low contact fatigue, so it is not suitable for gear, bearing and other parts which bear large fatigue stress load.The 12L14 has a tendency to be replaced by it.Its cutting performance is also very good.Suitable for more stringent applications where 12L14 cannot be used.

12L14 Free Cutting Steel Features

1. Easy car iron processing performance is good: the product has smooth cutting, excellent material, stable processing,

Good metallographic structure, stable chemical composition, small deviation, pure steel, not easy to damage the tool and other characteristics;

Very easy to cut on the lathe, tool life and productivity are increased by 40%;

2. Good electroplating performance: it is very easy to cut;It can drill deep holes and mill deep grooves.Machining efficiency

Compared with general steel can be greatly improved;Product electroplating performance is good, can replace copper products, greatly reduce the cost of products;

3. Easy car iron smoothness is good: the workpiece surface smoothness is good after the car processing;

4. Easy car iron environmental protection: in line with the European Union SGS environmental certification standards, and through the Swiss environmental certification.

Products can be exported to machinery and equipment: woodworking machinery, ceramic machinery, paper machinery, glass machinery, food machinery,

Construction machinery, plastic machinery, textile machinery, jack, hydraulic press, etc.;Electrical components: motor shaft,

Fan shaft, sewing machine shaft, etc.Furniture: especially export metal furniture, such as coffee tables, chairs, outdoor furniture;

Metal tools: garden tools, grill rack, screwdriver, anti-theft lock, etc.Hardware accessories: such as guide rail,

Machine keys, nuts, screws, round nails, hexagonal nails and octagonal nails and a variety of different specifications of standard parts;Cars,

Motorcycle spare parts, etc.

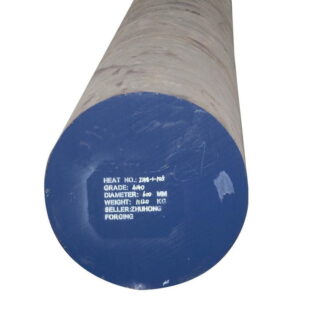

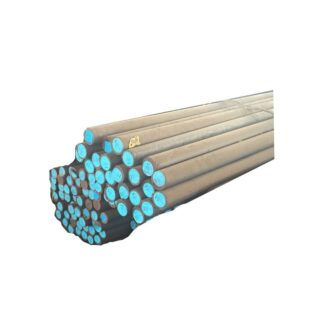

Free cutting steel round bar, wire, steel wire two:

They are as follows:

1.W (weight, kg) =F(sectional area mm2)×L(length, mm)×ρ(density, g/cm3)×1/10

Weight = Volume × Density (Free Cutting Steel Density 7.85)

2.W= 0.006165 × D × D (the weight obtained is the weight of steel per meter)

D = diameter mm

For round steel with diameter of 100 mm, find weight per m.Weight per m = 0.006165 ×100×100=61.65kg

Similar Material: 1215 Free Cutting Steel

Global Grade

American Grade: AISI 12L14,

Japanese Grade: SUM24L,

French Grade: S250PB,

German Grade: 95MNPB28,

International Grade: 11SMNPB28,

Chinese Grade: Y15PB.