Introduction to 1215 Free Cutting Steel:

Free cutting steel 1215 (rough, cold drawn, fine drawn round) free cutting steel, 1215 free cutting steel is a kind of hot rolled cold drawn bar steel and steel wire which is suitable for automatic goods production in cutting process by adding sulfur element to the steel to make it free cutting.

These steels can be machined at higher cutting speeds and greater depth of cut.

Due to the addition of the easy cutting elements in the steel, the cutting resistance of the steel decreases, and the characteristics of the easy cutting elements themselves and the compound formed by the lubrication of the cutting tool, easy to break chips, reduce wear and tear, thereby reducing the surface roughness of the workpiece, improve the tool life and production efficiency.

1215 because of the accuracy, good surface condition, easy to cut steel products can be directly used, such as spraying, sand, bending, drilling, but also according to the actual requirements of direct electroplating after fine drawing, eliminating a lot of machining time and save the cost of processing machinery configuration.

1215 Free cutting steel products are widely used in:

1215 Steel Mainly used for automatic cutting machine to process fasteners and standard parts, such as studs, screws, nuts, pipe joints, spring seats, etc.

A. Mechanical equipment: woodworking machinery, ceramic machinery, paper making machinery, glass machinery, food machinery, construction machinery, plastic machinery, textile machinery, jack, hydraulic press, etc.;

B. Electrical components: motor shaft, fan shaft, sewing machine shaft, etc.;

C. Furniture: especially export metal furniture, such as coffee tables, chairs and outdoor furniture;

D. Metal appliances: garden tools, grill rack, screwdriver, anti-theft lock, etc.;

E. Hardware accessories: such as guide rails, machine keys, nuts, screws, round nails, hexagonal nails, octagonal nails and various standard parts of different specifications;

F. Auto, motorcycle spare parts, etc.

Similar material: 12L14 Free Cutting Steel

Advantages of free cutting steel:

1215 easy – cut steel has high sulfur content, good cutting performance, high plasticity and higher strength.

1215 free cutting steel products have the following advantages:

A. Variety of shape and specification: by designing molds of different shapes, free cutting steel angles with different cross-section shapes and different specifications can be drawn into straight angles or rounded corners.

B. High precision: the use of high quality cemented carbide mold, to ensure the accuracy and uniformity of tolerance.

C. Smooth surface: advanced cold extrusion process makes the surface of free cutting steel products smooth and bright.

E. materials large savings: cold drawing process is the shape of the raw material of cold extrusion deformation to achieve the required specifications and tolerances, the consumption of raw materials, relative materials, using traditional lathe machining cutting through the free-cutting steel save material and time is very considerable, especially when the dosage of materials, material cost savings.

F. Processing time and saving of processing machinery: due to the accuracy and good surface condition, free cutting steel products can be directly used, such as spraying, grinding, bending, drilling, or according to the actual requirements of direct electroplating after fine drawing, eliminating a lot of machining time and saving the cost of processing machinery configuration

1215 Free cutting steel spot specification:

| Product Name | Size: mm | Material |

| Wire free cutting steel | Ф5.5-30 | 1215 Free-Machining Steel |

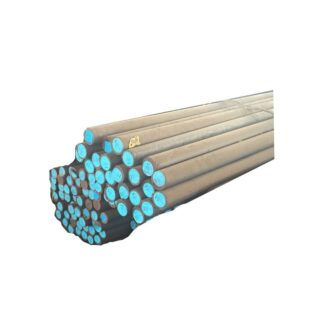

| Cold drawn round free cutting steel | Ф3.0-100 | ⬆ |

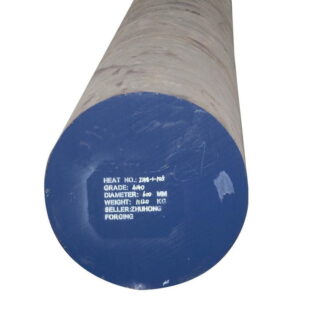

| Free cutting steel hot rolled round steel | Ф3.0-350 | ⬆ |

| Free cutting steel hot rolled round steel | Ф14-350 | ⬆ |

| Free cutting steel hot rolled sheet | 1-180 | ⬆ |

| Free-Machining Steel | 0.1-180 | ⬆ |

1215 Mechanical properties of free cutting steels

Tensile strength of 1215 Free-machining steel σb (MPa): (Hot Rolled)390~540;

1215 Free-machining steel(Cold-Drawn Steel)Thickness or diameter of steel 8~20 :530~755; >20~30 :510~735; >30 :490~685

Elongation of 1215 Free-machining steel δ5 (%): (Hot Rolled)≥22;(Cold-Drawn Steel)≥7.0

| Tensile strength (psi) | 68,000 – 78,000 |

| Yield strength (psi) | 65,000 – 75,000 |

| Elongation in 2” (%) | 15 – 20 |

| Reduction of area (%) | 50 – 60 |

| Brinell Hardness (BHN) | 150 – 170 |

1215 Free cutting steel chemical component:

C :≤0.09

Mn: 0.75-1.05

Si: ≤0.10

P: 0.04-0.09

S: 026-0.35

Pb: –

Note: Cold drawn 1215 steel bar is resulfurized and rephosphorized carbon steel. This grade is considered free machining, having excellent machinability due to its added sulfur, phosphorus. This grade, also referred to as “screw stock”, is heavily utilized for automatic screw machine operations. It’s also ideal for parts that require heavy machining and bright finishes. Due to its low carbon, this material has lower strength than other cold drawn grades.

Lion Metal Company stocks several diameters of this grade to meet your demands quickly. We also supply 1215 cold drawn bar to various industries like construction, automotive, and more.