Properties of steel 11SMnPb30 (1.0718)

| Weldability: Due to the high sulphur and phophorus content free-cutting steels not destined to heat treatment are not generally recommended for welding. Machinability: This steel grade is marked by a good machinability on machine tools and by an easy fragmentation of chips. In order to further improve its machinability, this steel grade can be supplied upon request with Te (tellurium) and Bi (bismuth) addition. |

Equivalent grades of steel 11SMnPb30 (1.0718)

| EU EN | Germany DIN,WNr | France AFNOR | Italy UNI | |||

| 11SMnPb30 |

|

|

|

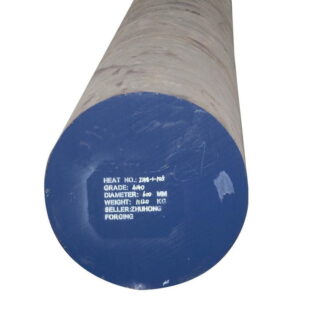

11SMnPb30 (DIN 1.0718) Free-cutting structural steel is similar in properties to 15SMn1SEO3 but offers better machinability. The 11SMnPb30 is used to make insignificant parts.11SMnPb30 is a free-machining steel with low carbon content. The term free-machining implies that the analysis is tailored to promote machinability at the expense of other properties. The material can be machined at high speeds and it is short-chipping, which expediates processing in unmanned machines.

11SMnPb30 (DIN 1.0718) Free-cutting structural steel is similar in properties to 15SMn1SEO3 but offers better machinability. The 11SMnPb30 is used to make insignificant parts.11SMnPb30 is a free-machining steel with low carbon content. The term free-machining implies that the analysis is tailored to promote machinability at the expense of other properties. The material can be machined at high speeds and it is short-chipping, which expediates processing in unmanned machines.The principal additions promoting machinability are sulphur and lead, both of which are present in an amount 0.3%, but a high phosphorous content can also contribute. The positive influence of lead for machinability derives from its low melting point whereby the particles of lead in the steel melt in the vicinity of the cutting edge thereby contributing locally to lubrication. The high level of machinability is further enhanced by cold drawing.

11SMnPb30 +C is standardised in SS-EN 10077 – 3. The (discontinued) SS-designation is 1914. The base steel 11SMnPb30 does not have very high strength but yield and tensile strengths are enhanced somewhat via cold drawing. The minimum prescribed level of yield strength varies depending on edge length over the range 440 – 245 MPa. The interval for tensile strength decreases and the minimum allowed elongation in a tensile test increases somewhat as the edge length of the bar increases. There is no guarantee for impact toughness.

The edge-length tolerance for 11SMnPb30 +C as cold-drawn squares is quite good, h11 as defined in ISO 286 – 2 or better. Furthermore, straightness is considerably better than what is typical for hot-rolled square bars and the maximum height of arc is 0.001 times bar length. Straightness as a property is important for processing in bar-feed machines.

The weldability of 11SMnPb30 is limited as a consequence of the high levels of sulphur and lead. However, should the application require that the part has a wear-resistant surface, 11SMnPb30 +C can be case hardened.

11SMnPb30 Chemical Composition:

- Carbon C: ≤0.14

- Si Si: 0.05 Max

- Manganese Mn: 0.90 to 1.30

- Sulfur: 0.27 ~ 0.33

- Phosphorus P: 0.11 Max

- Lead Pb: 0.20 ~ 0.35

11SMnPb30 Mechanical Properties:

- Tensile strength σb (MPa):

- (hot rolled) 390 to 540;

- (cold drawn) Steel thickness or diameter:

- 8 to 20 hours: 530 to 755;

- > 20 to 30 hours: 510 to 735;

- > 30 hours: 490 to 685

- Elongation δ5 (%): (hot-rolled) ≥ 22; (cold-rolled) ≥ 7.0

- Section shrinkage ψ (%): (hot-rolled) ≥36

- Hardness: (hot rolled) ≤ 170HB; (cold drawn steel) 152 ~ 217HB

Delivery status:

Hot or cold drawn state delivery, delivery status should be specified in the contract.

| ReH | Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d elasticite minimale |

| Rm | Tensile strength / Zugfestigkeit / Resistance a la traction |

| A | Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal |

| J | Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc |

Heat treatment conditions

|

|

Chemical composition of steel 11SMnPb30 (1.0718), Standards of steel 11SMnPb30 (1.0718) Mechanical Properties of steel 11SMnPb30 (1.0718) Equivalent grades of steel 11SMnPb30 (1.0718) steel 11SMnPb30 (1.0718) Tensile Strength, Elongation, Proof strength , Hardness |