Q235 Steel Plate Description

GB Q235B mild Steel is chinese standard Q235 steel series of low carbon structural steel, Q235 steel series have A, B, C , D, E quality grade. GB Q235B steel is equivalent with the European standard of DIN EN S235JR.

Related Specifications GB/T 700-1988

Chemical composition

| C(%) | 0.12~0.20 | Si(%) | ≤0.30 | Mn(%) | 0.30~0.70 |

| P(%) | ≤0.045 | S(%) | ≤0.45 | ||

Form of Supply

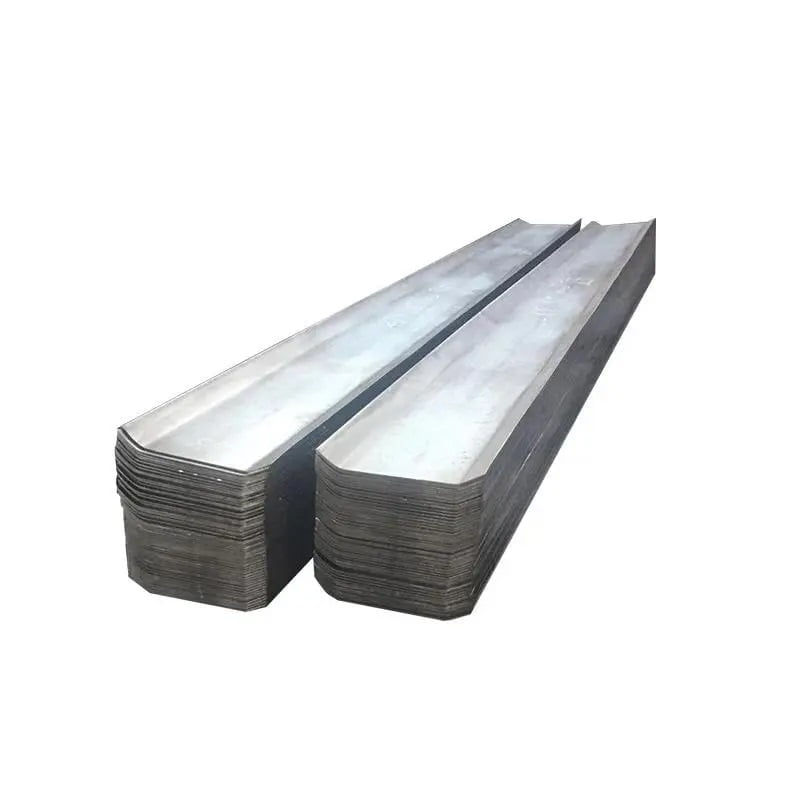

GB Q235B mild low carbon steel, we can supply the round bar, flat bar, plate, hexagonal and square block. Diameters can be sawn to your required lengths as one offs or multiple cut pieces. Rectangular pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

Meaning and Designation

“Q” is the first letter of Chinese spelling of “Qufu dian”, which means Yield Point.

“235” refers to the minimum yield strength 235 MPa tested with steel bar diameter or plate thickness ≤ 16mm.

A, B, C and D represent quality grades.

Features and Applications

Q235 steel has good plasticity, toughness and weldability, as well as a moderate strength, good cold bending performance. Q235 material is commonly rolled into wire rod or round steel, square steel, flat steel, angle steel, I beam, channel steel, other sections and steel plates. These products are widely used in construction and engineering welded structures, to make steel bars or build factory buildings, high voltage transmission towers, bridges, vehicles, boilers, containers, etc., and also used as a mechanical part with less demanding performance such as less stressed rods, connecting rods, screws, nuts, ferrules, brackets, and stands, etc.

Q235 Steel Properties (Data Sheet and Specification)

The following tables show Q235 steel properties, datasheet and specification, including Q235A, Q235B, Q235C and Q235D steel, including chemical composition, physical and mechanical properties, etc.

Q235A, Q235B, Q235C, Q235D Steel Chemical Composition

The table below lists Q235 material chemical composition based on heat analysis.

| Chemical Composition (heat analysis), %, ≤ | |||||||

| Steel Grade | Quality Grade | C | Si | Mn | P | S | Deoxidation Method |

| Q235 | Q235A | 0.22 | 0.35 | 1.40 | 0.045 | 0.050 | Rimmed / Killed |

| Q235B | 0.20 | 0.35 | 1.40 | 0.045 | 0.045 | Rimmed / Killed | |

| Q235C | 0.17 | 0.35 | 1.40 | 0.040 | 0.040 | Killed | |

| Q235D | 0.17 | 0.35 | 1.40 | 0.035 | 0.035 | Exceptionally Killed | |

Note: Q235B carbon content C can be ≤0.22% by agreement.

Physical Properties

Notes:

- 10-6·K-1 = 10-6/K

- 1 Ω·mm²/m = 1 μΩ·m

- 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3

- 1 GPa = 1 kN/mm2

- 1 MPa = 1 N/mm2

| Physical Properties | |

| Density, g/cm3 (lb/in3) | 7.85 (0.284) |

| Melting point, °C (°F) | 1450-1530 (2640-2800) |

| Specific heat capacity, J/(Kg·K) | 470 at 20 °C (68 °F) |

| Electrical resistivity, μΩ·m | about 0.15 (20 °C) |

| Elastic modulus, GPa (ksi) | 200 (29 x 103) |

| Thermal conductivity, (W/m·K) | 53-49 (0-100 °C) |

| Coefficient of thermal expansion, (10-6/K) | 11.3-11.6 at 20-100 °C (68-212 °F) |

| Young’s modulus, GPa (ksi) | 200 (29 x 103) |

| Poisson’s ratio | 0.24-0.28 |

Mechanical Properties

Yield strength and tensile strength are listed in the table below.

1 MPa = 1 N/mm2

| Yield Strength (MPa, ≥); Thickness or Dia. (d) mm | Tensile Strength (MPa) | ||||||

| Steel Grade | Quality | d≤16 | 16< d ≤40 | 40< d ≤100 | 100< d ≤150 | 150< d ≤200 | d≤100 |

| Q235 | Q235A | 235 | 225 | 215 | 195 | 185 | 370-500 |

| Q235B | |||||||

| Q235C | |||||||

| Q235D | |||||||

Minimum Elongation

| Elongation (≥ %); Thickness or Dia. (d) mm | |||||

| Steel Grade | d≤40 | 40< d ≤60 | 60< d ≤100 | 100< d ≤150 | 150< d ≤200 |

| Q235 | 26 | 25 | 24 | 22 | 21 |

Minimum Charpy Impact

| Charpy impact (V notch) | |||

| Steel Grade | Quality | Temperature. °C | Impact energy (longitudinal, ≥ J) |

| Q235 | Q235A | – | – |

| Q235B | +20 | 27 | |

| Q235C | 0 | ||

| Q235D | -20 | ||

Bending Test Results of Q235 Material

| Cold Bending Test 180° (B=2a) | |||

| Grade | Sample Orientation | Steel Dia. (d) of Curve Center | |

| d≤ 60mm | 60<d≤100 mm | ||

| Q235 | Vertical | a | 2a |

| Horizontal | 1.5a | 2.5a | |

B= Sample Steel Width; a= Sample Diameter or Thickness.

Steel rolled with Q195 and Q235B grade rimmed steel, the thickness or diameter of which is not more than 25mm.

Q235 Steel Equivalent Material

Q235steel equivalent ASTM, European EN (German DIN EN, British BS EN, French NF EN…), Australian AS/NZS, Japanese JIS, and Indian standard are listed in the table below.

| Q235 Steel Equivalent Grades | |||||||||||||||

| Chinese | US | European Union | Britain (UK) | Australian | Japan | Indian | ISO | ||||||||

| Standard | Grade | Standard | Grade | Standard | Grade (Steel Number) | Standard | Grade (Steel Number) | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| GB/T 700 | Q235A | BS 970 Prat 1 | 080A15 | JIS G 3101; JIS G 3106 | SS400; SM400A | IS 2062 | E250A | ||||||||

| GB/T 700 | Q235B | ASTM A36; ASTM A283/A283M | A36; Grade D | EN 10025-2 | S235JR (1.0038) | BS EN 10025-2 | S235JR (1.0038) | AS/NZS 3678 | 250 | JIS G3101; JIS G3106 | SS400; SM400A | IS 2062 | E250B | ||

| GB/T 700 | Q235C | ASTM A36; ASTM A283/A283M; ASTM A573/A573M | A36; Grade D; Grade 58 | EN 10025-2 | S235J0 (1.0114) | BS EN 10025-2 | S235J0 (1.0114) | AS/NZS 3678 | 250L0 | JIS G3106 | SM400A, SM400B | IS2062 | E250C | ISO 630-2 | S235B |

| GB/T 700 | Q235D | ASTM A36; ASTM A283M | A36; Grade D | EN 10025-2 | S235J0 (1.0114); S235J2 (1.0117) | BS EN 10025-2 | S235J0 (1.0114); S235J2 (1.0117) | AS/NZS 3678 | 250L20 | JIS G3106 | SM400A | IS2062 | E250 C | ISO630-2 | S235B, S235C |

Note:

- S235JRG2 and S235J2G4 are old designations in EN 10025:1993, S235JRG2 is replaced by the new designation S235JR (1.0038), and S235J2G4 replaced by S235J2 (1.0117) in EN 10025-2 since 2004.

- Material Q235 australian equivalent is grade 250 in standard AS/NZS-3678; Indian equivalent is E250 in standard IS-2062.