Nimonic 105 Introduction

Super alloys or high performance alloys are available in a variety of shapes and contain elements in different combinations to obtain a specific result. These alloys are of three types that include iron-based, cobalt-based and nickel-based alloys. The nickel-based and cobalt-based super alloys are available as cast or wrought based alloys based on composition and application.

Super alloys have good oxidation and creep resistance and can be strengthened by precipitation hardening, solid-solution hardening and work hardening methods. They can also function under high mechanical stress and high temperatures and also in places that require high surface stability

Super alloy Nimonic 105™ is a nickel-cobalt-chromium alloy. The following datasheet provides an overview of Nimonic 105™.

NIMONIC alloy 105 is produced by high frequency melting in air followed by casting in air, or, for more critical applications the alloy is produced by vacuum melting and electroslag refining. The alloy is used for turbine blades, discs, forgings, ring sections, bolts and fasteners.

A precipitation-hardenable nickel-chromium-cobalt alloy with an addition of molybdenum for solid-solution strengthening. It is similar to NIMONIC alloy 105 but has higher levels of aluminum and titanium for increased strengthening by precipitation hardening. The alloy has high strength and creep resistance at temperatures to about 1850°F (1010°C). Used for turbine blades in aircraft gas turbines.

Nimonic 105 Physical Properties:

| Melting Point (°C) | Density | Modulus of Elasticity in Tension |

|---|---|---|

| 1290 – 1345 | 8.01g/cm3 | 188 GPa |

Nimonic 105 Mechanical Properties:

| Tensile Strength Minimum (psi) | Yield Strength Minimum 0.2% offset (psi) | % Elongation in 2″ Minimum |

|---|---|---|

| 167,000 | 112,000 | 25 |

Nimonic 105 Chemical Composition:

| C | Si | Cu | Fe | Mn | Cr | Ti | Al | Co | Mo | Pb | S | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.12 | 1.0 | 0.2 | 1.0 | 1.0 | 14.0-15.7 | 0.9-1.5 | 4.5-5.5 | 18.0-22.0 | 4.5-5.5 | 0.0015 | 0.010 | 0.003-0.010 | 0.15 | Bal |

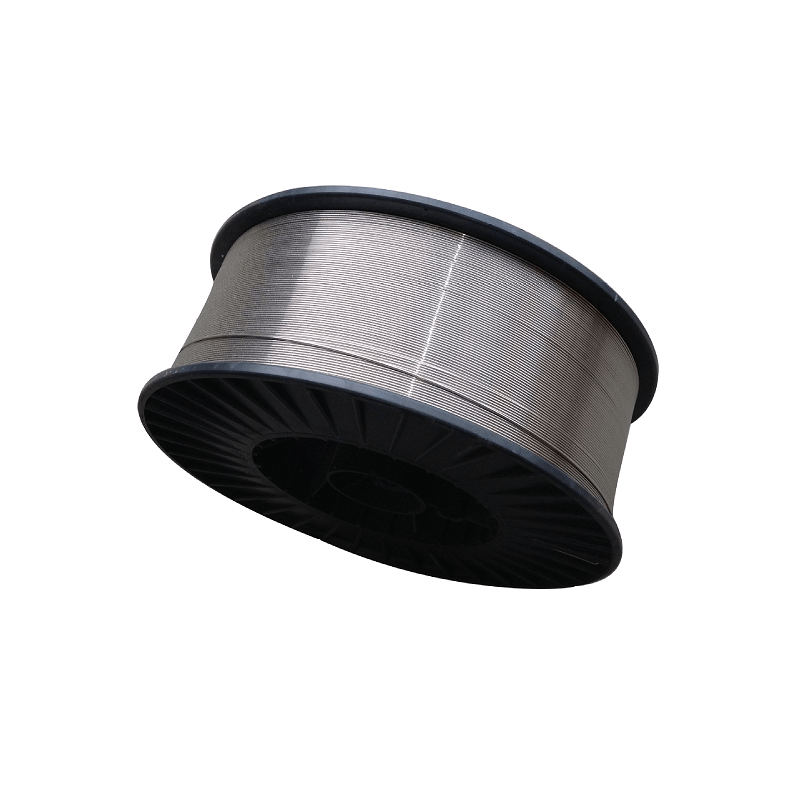

Nimonic 105 Welding:

Welding techniques recommended for Nimonic 105 include gas-tungsten arc welding, gas metal-arc welding, submerged-arc welding and shielded metal-arc welding. Usage of a matching alloy filler metal is recommended for the welding process and if a matching filler is absent, an alloy rich in Ni, Co, Cr, Mo is can be used. During the absence of a matching filler metal.

Nimonic 105 Heat Treatment:

Nimonic 105 can be heat treated in 4 four steps. The steps are as follows: Solution annealing for 4 h at 1149°C (2100°F) followed by air cooling. Heating for 16 h at 1056°C (1925°F) followed by air cooling. Heating for 16 h at 849°C (1560°F). Air cooling to reach precipitation-hardening.

Nimonic 105 Properties:

| Mechanical & Physical Properties | 21.1°C | 93.3°C | 148.9°C | 204.4°C | 315.6°C | 371.1°C | 426.7°C | 537.8°C | 648.9°C | 750°C | 815°C | 870°C | 982°C | 1093°C | 1204°C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ultimate Tensile Strength /MPa | 1140 | 1123 | 1123 | 1084 | 1091 | 1101 | 1101 | 1064 | 1038 | – | – | – | 175 | – | – |

| 0.2% Yield Strength /MPa | 776 | 762 | 762 | 735 | 735 | 743 | 743 | 740 | 720 | – | – | – | 152 | – | – |

| Reduction of area % | 31 | 31 | 31 | 38 | 30 | 39 | 39 | 37 | 38 | – | – | – | 73 | – | – |

| Elongation % | 22 | 20 | 20 | 21 | 20 | 24 | 24 | 23 | 25 | – | – | – | 42 | – | – |

| Minimum Creep 0.0001% per hr | – | – | – | – | – | – | – | – | 428 | 232 | 93 | 54 | – | – | – |

| 10,000 hr Rupture Strength | – | – | – | – | – | – | – | – | 471 | 263 | 135 | 65 | 12 | – | – |

| Coefficient of Thermal Expansion /µm/m°C | 12.2 | 12.2 | 12.2 | 12.8 | 13.1 | 13.4 | 13.4 | 13.7 | 14 | – | – | – | 18 | – | – |

| Thermal Conductivity /kcal/(hr.m.°C) | 9.363 | 10.41 | 10.41 | 11.67 | 12.89 | 14.04 | 14.04 | 15.2 | 16.02 | – | – | – | 22.54 | – | – |

| Modulus of Elasticity / GPa | 188 | 184 | 184 | 179 | 174 | 168 | 168 | 161 | 154 | – | – | – | 110 | – | – |