MONEL K-500 Description

MONEL K-500 alloy has the same corrosion resistance as 400, but has higher mechanical strength and hardness. It has good corrosion resistance and long-term structure stability.

It is mainly used to manufacture turbine blades and gas turbine blades whose working temperature is below 750℃ on aeroengines; Used for manufacturing fasteners and springs on ships; Pump and valve parts for chemical equipment; Pulp blades on paper making equipment, etc.

Product specification range:

Forgings, bars, dimensions can be zero cut, strip, ring, wire, flange and other products can be produced according to customer requirements.

Features | Monel K-500 (UNS N05500)MONEL K-500 alloy has the same corrosion resistance as 400, but has higher mechanical strength and hardness. It has good corrosion resistance and long-term structure stability. It is mainly used to manufacture turbine blades and gas turbine blades whose working temperature is below 750℃ on aeroengines; Used for manufacturing fasteners and springs on ships; Pump and valve parts for chemical equipment; Pulp blades on paper making equipment, etc. | ||||||||

Summary | A precipitation-hardenable nickel-copper alloy that combines the corrosion resistance of MONEL alloy 400 with greater strength and hardness. It also has low permeability and is nonmagnetic to temperatures as low as -150°F (-101°C). Used for pump shafts, oil-well tools and instruments, doctor blades and scrapers,springs, valve trim, fasteners, and marine propeller shafts. | ||||||||

Standard | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

Product Forms | |||||||||

Chemical composition (wt.-%) according to ASTM | Min. | Max. | Min. | Max. | Min. | Max. | |||

| Ni | 63 | Cu | 27 | 33 | C | 0.18 | |||

| Cr | Co | Si | 0.5 | ||||||

| Fe | 2 | Al | 2.3 | 3.15 | P | ||||

| Mo | Ti | 0.35 | 0.85 | S | 0.01 | ||||

| W | Mn | 1.5 | N | ||||||

Physical | Density,g/cm3 | 8.44 | |||||||

Constants | Melting Range,℃ | 1315-1350 | |||||||

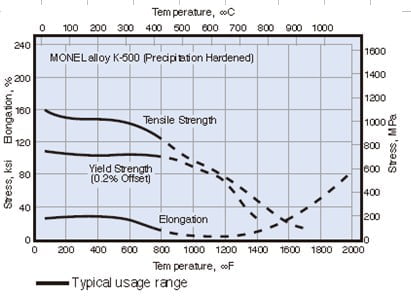

Typical | (Precipitation Hardened) | ||||||||

Mechanical | Tensile Strength, ksi | 160 | |||||||

Properties | Mpa | 1100 | |||||||

| Yield Strength (0.2% Offset), ksi | 115 | ||||||||

| Mpa | 790 | ||||||||

| Elongation, % | 20 | ||||||||

| |||||||||

Microstructure | Monel K-500 which is produced by adding aluminum and titanium to the basic Monel nickel-copper composition also has a face-centered cubic structure. In the agehardened condition a submicroscopic gamma prime Ni3Al phase is | ||||||||

Characters | Monel K-500 has excellent corrosion resistance in an extensive range of natural and chemical environments, excellent resistance to chloride-ion stress-corrosion cracking and very high strength and hardness. After age-hardening, Monel K-500 has approximately 2 to 3 times higher mechanical properties than the nickel-copper alloy (Monel 400), high tensile properties up to about 650 ℃, good corrosion fatigue resistance and ow permeability with non-magnetic down to -135 ℃. | ||||||||

Corrosion Resistance | In general, the corrosion resistance of Monel K500 is similar to that of Monel 400. Excellent resistance is shown to a wide range of media from pure water to mineral acids, salts and alkalis. | ||||||||

| Monel K-500 is virtually immune to chloride-ion stress-corrosion cracking. In the aged condition, the alloy may be susceptible to stress-corrosion cracking in moist, aerated hydrofluoric acid vapour at stresses near the yield strength. | |||||||||

| In high-velocity seawater and in marine atmospheres, good corrosion resistance is shown but, in slow-moving or stagnant seawater, pitting may occur. Nicorros Al also shows good resistance in sour-gas environments. | |||||||||

Applications | |||||||||

| Monel K-500 finds wide application in the marine, chemical, petrochemical and shipbuilding industries. | |||||||||

| Typical applications include: | |||||||||

| 1. Valve seals, pump sleeves and wear rings in marine | |||||||||

| environments – high strength and resistance to seawater; | |||||||||

| 2. Fasteners, e.g. bolts, used in marine atmospheres and tidal waters – resistance to chloride-containing environments; | |||||||||

| 3. Doctor blades and scrapers; | |||||||||

| 4. Towing cable armouring – high strength, non-magnetic properties and resistance to seawater; | |||||||||

| 5. Oil well drilling equipment such as non-magnetic drill collars, valves and instrumentation sleeves – resistance to chloride-containing media and sour-gas environments; | |||||||||

| 6.Springs – resistance to a variety of corrosive media; | |||||||||

| 7.Aviation instrument components – non-magnetic properties. | |||||||||