Hastelloy 188 Specifications

Haynes 188 is covered by the following specifications:

UNS R30188

Rod, Bar, Wire and Forging Stock: AMS 5772

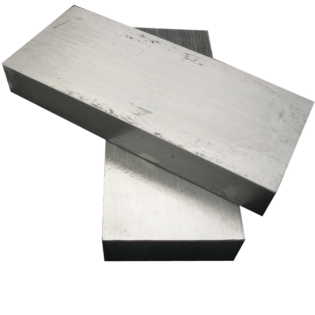

Plate, Sheet and Strip: AMS 5608

Welding Wire: AMS 5801

Trademark Notice: Some names are trade names and/or trademarks of specific manufacturers. American Special Metals, Corp. is not affiliated with any manufacturer(s). Orders will be filled to meet specifications from any available source(s). Names are listed solely for reference to help identify products consistent with listed specifications.

Haynes 188 Alloy is a Registered Trademark of Haynes International and Its subsidiaries.

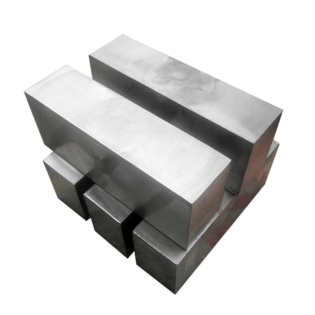

Hastelloy 188 Nickel Based Superalloy

Hastelloy 188 is a solid solution strengthened drill-based high temperature alloy. It is strengthened by adding 14% tungsten to make the alloy have excellent high temperature thermal strength. The addition of higher content of chromium and trace lanthanum makes the alloy has good high temperature oxidation resistance. Satisfactory process performance such as forming and welding, suitable for manufacturing aero engines at temperatures above 980℃

The parts that require high strength and oxidation resistance below 1100°C. It can also be used on space engines and space shuttles. Can produce and supply a variety of deformed products, such as thin plates, plates, strips, bars, forgings, wires and precision castings.

HAYNES® 188 alloy has good forming and welding characteristics. It may be forged or oth- er hot-worked, providing that it is held at 2150°F (1175°C) for a time suf cient to bring the entire piece to temperature. As a consequence of its good ductility, 188 alloy is also readily formed by cold working. The alloy does work-harden rapidly, however, so frequent inter- mediate annealing treatments may be needed for complex component forming operations. All hot- or cold- worked parts should be annealed and rapidly cooled in order to restore the best balance of properties.

The alloy can be welded by both manual and automatic welding methods, including gas tungsten arc (TIG), gas metal arc (MIG), electron beam and resistance welding. It exhibits good restraint welding characteristics.

Hastelloy 188 chemical composition:

| C | Cr | Ni | W | Fe | B | La | Mn | Si |

| 0.05-0.15 | 20-24 | 20-24 | 13-16 | 3.0 | 0.015 | 0.03-0.12 | 1.25 | 0.20-0.50 |

Heat Treatment:

Wrought HAYNES® 188 alloy is furnished in the solution heat treated condition, unless oth- erwise speci ed. The alloy is normally solution heat-treated at 2125-2175°F (1163-1191°C) and rapidly cooled or water quenched for optimal properties.

Annealing at temperatures less than the solution heat-treating temperature will produce some carbide precipitation in alloy 188, which may affect the alloy’s properties.

Hastelloy 188 alloy applications:

Hastelloy 188 alloy is widely used abroad in the manufacture of high-temperature parts of gas turbines and missiles, such as combustion chambers, exhaust nozzles and heat exchangers in the nuclear energy industry. High-temperature components such as the flame tube and guide vanes of the combustion chamber of aero engines made of this alloy in China have passed the test of long-term test runs and have been put into production and application. In the manufacturing process of processing the alloy sheet into parts, any process (such as heat treatment, welding, etc.) should prevent carburization and copper pollution, so as not to damage the mechanical properties and corrosion resistance of the alloy.

Hastelloy 188 alloy has a high service temperature, up to 1100°C, has good oxidation resistance, comprehensive mechanical properties and structural stability, and has good cold and hot processing plasticity; the alloy has strong resistance to vulcanization and corrosion resistance to sodium salts

Hastelloy188 is a solid solution strengthened cobalt-based high-temperature alloy. The addition of 14% tungsten solid solution strengthens the alloy to have excellent high-temperature thermal strength. The addition of higher content of chromium and trace lanthanum makes the alloy has good high-temperature oxidation resistance. It has satisfactory forming and welding process performance, and is suitable for manufacturing parts of aero engines that require high strength below 980°C and oxidation resistance below 1100°C. It can also be used on space engines and space shuttles.

Can produce and supply a variety of deformed products, such as thin plates, medium plates, strips, bars, forgings, wires and precision castings.