P20 Tool Steel Description

P20 die steel is a kind of mold welding material model, the earliest is P20, followed by P20H, P20Ni have come out. P20 steel is suitable for making plastic molds and die casting of low melting point metals. This steel has good machinability and mirror abrasive properties.

Prehardened plastic die steel. Widely used in China, factory hardness HRC30~42, suitable for large and medium-sized precision molds, suitable for long-term production of high quality plastic molds, used for large mold frame. This steel has good machinability and general polishing ability.

Relevant P20 Tool Steel Specification and Equivalent Steel Grades

| Country | USA | German | GB/T |

| Standard | ASTM A681 | DIN EN ISO 4957 | GB/T 1299 |

| Grades | P20 | 1.2311 | 3Cr2Mo |

P20 Tool Steel(plastic mould steel) Chemical Component

| C | Si | Mn | P | S | Cr | Mo | Ni |

0.28-0.4 | 0.2-0.8 | 0.6-1 | ≤0.03 | ≤0.03 | 1.4-2 | 0.3-0.55 | 0.05-0.10 |

P20 Tool Steel(plastic mould steel)

LION METAL is ASTM P20 Tool Steel stockholders and suppliers from china(Shanghai). we have more our 26 years experience in special steel supply.

ASTM P20 Steel is a good quality plastic tool steel, P20 steel belong to the high quality medium carbon,Pre-hardness(28~34HRc) plastic mould steel. It no need further heat treatment. so you don’t have any worry about distortion or cracking.

Relevant P20 Tool Steel Specification and Equivalent Steel Grades

| Country | USA | German | GB/T |

| Standard | ASTM A681 | DIN EN ISO 4957 | GB/T 1299 |

| Grades | P20 | 1.2311 | 3Cr2Mo |

P20 Steel Properties Related Specifications ASTM A681-1999 | JIS G4404(2000) | GB 1299

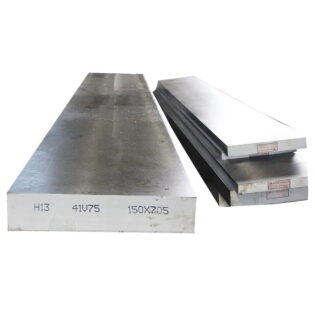

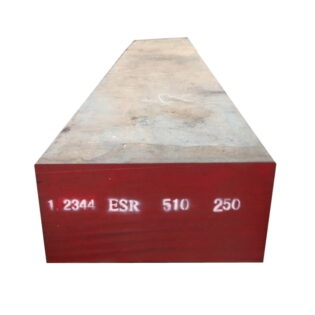

AISI P20 Steel Plate Materials

ASTM A681 C Mn P S Si Cr Mo P20 0.28 0.4 0.6 1 0.03 0.03 0.2 0.8 1.4 2 0.3 0.55 DIN ISO 4957 C Mn P S Si Cr Mo 1.2311 0.35 0.45 1.3 1.6 0.03 0.03 0.2 0.4 1.8 2.1 0.15 0.25 GB/T C Mn P S Si Cr Mo GBT 1299 0.28 0.4 0.6 1 0.03 0.03 0.2 0.8 1.4 2 0.3 0.55

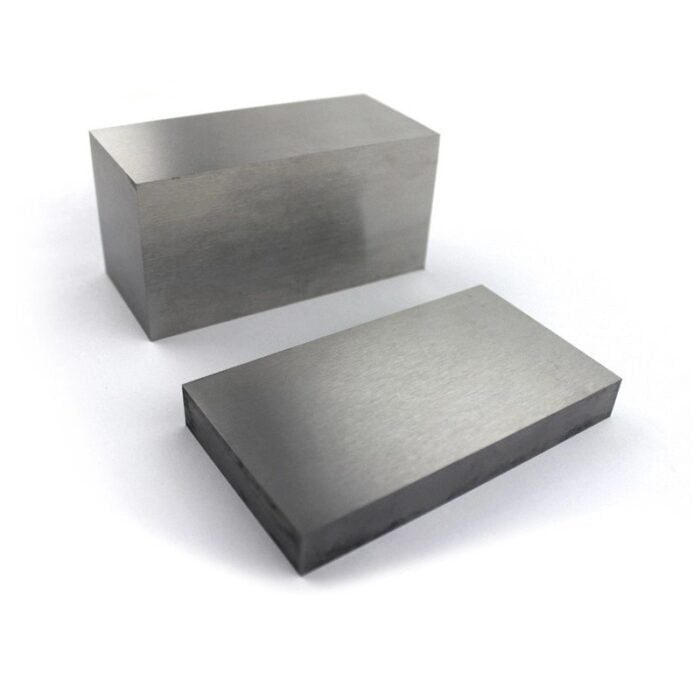

Form of Supply

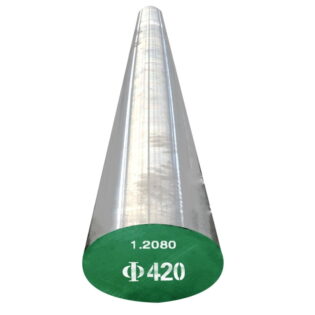

ASTM P20 tool steel, we can supply the p20 steel round bar, steel flat bar, steel plate, hexagonal steel bar and steel square block. P20 steel Round bar can be sawn to your required lengths as one offs or multiple cut pieces. Rectangular pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

Applications

ASTM P20 Tool steel is a American plastic Die steel material, the steel by “super clean” production process, pre hardened, showing the height of micro pure and excellent homogeneous structure, excellent polishing and light etching engraving.

ASTM P20 Tool steel is a American plastic Die steel material, the steel by “super clean” production process, pre hardened, showing the height of micro pure and excellent homogeneous structure, excellent polishing and light etching engraving.

After heat treatment, processing and polishing performance is good, can be carried out, and can be processed, suitable for the surface treatment of chrome, material hardness, good toughness, good mechanical processing performance.

Gold microstructure is martensite and bainite structure.

Main be applied to in plastic steel mold. like car injection moulding, PVC plastic injection molding.

Regular size and Tolerance

Round bar: Diameter Ø 5mm – 3000mm

Plate: Thickness 5mm – 3000mm x Width 100mm – 3500mm

Flat bar: 5mm – 105mm

| |||

| Diameter (mm) | Diameter Tolerance (mm) | Diameter (mm) | Diameter Tolerance (mm) |

| ≤12.70 | -0.13~0.30 | >50.80~63.5 | -0.25~0.76 |

| 12.7~25.40 | -0.13~0.41 | >63.50~76.20 | -0.25~1.02 |

| >25.4~38.10 | -0.15~0.51 | >76.20~101.60 | -0.30~+1.27 |

| >38.1~50.80 | -0.20~0.64 | >101.60~203.20 | -0.38~3.81 |

| |||

| Thickness (mm) | Thickness Tolerance (mm) | Thickness (mm) | Thickness Tolerance (mm) |

| ≤25.4 | -0.41~0.79 | >127~152 | -1.60~2.39 |

| >25.4~76 | -0.79~1.19 | >178~254 | -1.98~3.18 |

| >76~127 | -1.19~1.60 | >254~305 | -2.39~3.96 |

Others have not specified size, pls contact our experienced sales team.

Properties

- The vacuum degassing refining treatment of pure steel, suitable for polishing or etching processing plastic mold.

- Pre-hard state supply, no need in the heat treatment can be directly used for mold processing, shorten the construction period.

- After forging and rolling processing, the structure is compact, 100% ultrasonic inspection, no pores, needle hole defects.

USES:

- Thermoplastic injection mold, extrusion mold.

- Thermoplastic plastic blow mold.

- Heavy duty mold main parts.

- Cold structure parts.

- Commonly used in the manufacture of TV case, washing machine, refrigerator shell, bucket, etc.

Processing

(1) Round bar and flat sections can be cut to your required sizes.

(2) Round bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances.

(3) Is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Forging of Plastic mould steel AISI P20 steel material

Slowly Heat to 930-1050 °C, keep the temperature to heat thoroughly. Start forging. Finished cool slowly.

Annealing of Din P20 plastic mold tool steel material

Heat to 775 to 790 °C, soak enough time, ensure heat thoroughly. then cool in the heat treatment furnace.

Quenching of p20 material

820-840°C, quench in oil. get p20 steel material hardness 28~34HRc

Tempering of P20 plastic mold steel grade material

Heat uniformly at the tempering temperature for P20 tool steel material. keep enough time, then cool in air.

Advice temperature 100 to 600°C. more P20 mold tool steel heat treatment data, pls contact your heat treatment supplier,.

Contact our experienced sales team to help you with your P20 Tool steel questions

by Email or Telphone. The P20 Steel questions will be reply in 24 hours.