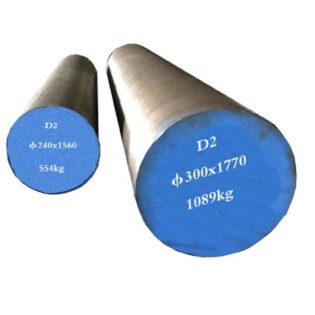

Cr12Mo1V1 Description

Cr12Mo1V1 is a high carbon and high chromium cold work die steel widely used in the world.

It belongs to leistenite steel and has high hardenability, hardenability and high wear resistance.

Good oxidation resistance at high temperature, good corrosion resistance after quenching and polishing, small deformation during heat treatment.

China Grade: Cr12Mo1V1

Source: D2 Steel, USA

The chemical composition of Cr12Mo1V1 die steel is exactly the same as that of D2.

The purpose of Cr12Mo1V1 die steel is the same as that of Cr12MoV. For more demanding die parts.

Cr12Mo1V1 Introduce

Cr12Mo1V1 die steel is a high carbon and high chromium type cold work die steel widely used in the world. It belongs to leistenite steel.D2 steel from the United States (AISI, ASTM). Our original is the former Soviet Union’s X12, now the Russian X12MΦ.

Cr12Mo1V1 die steel is a high carbon and high chromium type cold work die steel widely used in the world. It belongs to leistenite steel.D2 steel from the United States (AISI, ASTM). Our original is the former Soviet Union’s X12, now the Russian X12MΦ.

Cr12MoV die steel as early as YB-7 alloy tool steel standard on the standard, all have a long history of use.

D2 die steel was introduced in 1985, named Cr12Mo1V1, to distinguish with Cr12MoV, and included in the 1985 GB1299-1985 standard.

The chemical composition of Cr12Mo1V1 die steel is exactly the same as that of D2.

After many years of practice, it has been proved that the properties of Cr12Mo1V1 die steel are better than Cr12MoV die steel.

Because the content of Mo and V of steel is higher than that of Cr12MoV steel, and it also contains Co, the structure of steel is improved, and its strength, toughness and wear resistance are improved.

World Steel Grades

Almost all industrially advanced countries have incorporated this steel into national standards and quasi-national standards, such as BD2(BS) of the United Kingdom, X155 CrMOV12-1 of Germany, X160 CrMOV12 (NF) of France, and X155CrVMO12-1KV (UNI) of Italy.

Japan’s SKD11(JIS) die steel is between China’s Cr12Mo1V1 and Cr12MoV in composition, but its V content is low and it does not contain CO. However, Japan regards SKD11 as D2.

The Swedish SIS does not have the same type of steel, but the Swedish die steel manufacturers, such as Udholm (UHB), have the same grade of Sverker21, and ASSAB also has the steel with the same grade of XW-41.

The K110 from BÖHLER in Austria. DC11 of Daido Steel Co., Ltd., Hitachi SLD of Hitachi Metals Co., Ltd., CDS11 of NACHI-Fujikoshi Co., Ltd., SKD11 of Aichi Steel Co., Ltd., QC11 of Sanyo Special Steel Co., Ltd., GS-379 of ThyssenKrupp Co., Ltd., and ISO 160CrMOV12.

Russia changed X12M of the former Soviet Union into X12Φ, but its Mo and V content is still low, which is only equivalent to China’s Cr12MoV die steel.

The purpose of Cr12Mo1V1 die steel is the same as that of Cr12MoV. For more demanding die parts.

Chemical Component

C | Si | Mn | P | S | Cr | Mo | V | Other |

1.40~1.60 | ≦0.60 | ≦0.60 | ≦0.030 | ≦0.030 | 11.00~13.00 | 0.70~1.20 | ≦1.10 | Co≦1.00 |

Heat Treatment

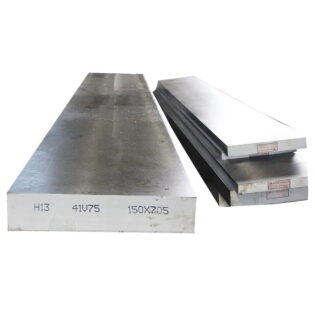

Heat treatment process of steel of Cr12Mo1V1 (D2) mould

Stress Relieving

After rough machining, the workpiece is heated to 600~650°C, held for 2h, and then cooled to 500°C with the furnace.

Quenching

The workpiece is slowly heated to 600°C, and the heat is held for 20min for the first preheating. After the average temperature rises to 850°C, the heat is held for 30min for the second preheating, and finally the temperature is raised to 1020~1040°C, and the heat is held for 25~40min, and the furnace is air-cooled.

Tempering

It should be tempered immediately after quenching, and tempered at least twice, each time the holding time is not less than 2H.

Note: after quenching should be timely tempering, to prevent cracking, and to prevent surface decarbonization, the gauge and high precision mold should be cryogenic treatment (-70°C), and use high temperature tempering, reduce the deformation of the workpiece, high temperature tempering temperature 500~560°C, hardness is greater than 58HRC.

Physical Properties

The physical properties of Cr12Mo1V1 steel are shown in Table 2-2-1 and Table 2-2-2. The elastic modulus is 207,000 MPa and the mass heat capacity Cp at constant pressure is 461J/(kg·K).

Table 2-2-1 Critical temperature of Cr12Mo1V1 steel

Critical point | Ac1 | Acm | Ar1 | Arcm | Ms |

Temperature (approximate) /°C | 810 | 875 | 695 | 190 |

Temperature/°C | 20~100 | 20~200 | 20~300 | 20~400 |

Line (expansion) expansion coefficient /°C-1 | 10.5×10-6 | 11.5×10-6 | 11.9×10-6 | 12.2×10-6 |

Scope of application

Cr12Mo1V1 is a high carbon and high chromium cold work die steel widely used in the world. It belongs to leistenite steel and has high hardenability, hardenability and high wear resistance.

Good oxidation resistance at high temperature, good corrosion resistance after quenching and polishing, small deformation during heat treatment.

CR12Mo1V1 is suitable for manufacturing all kinds of high precision and long life cold working dies, cutting tools and measuring tools, such as: complex shape punching die, cold extrusion die, rolling wheel, rolling wheel, cold cutting tool and precision measuring tools.