Product Introduction:

C90810 High Tin Bronze is a copper-based alloy known for its exceptional strength, wear resistance, and corrosion resistance. This alloy is particularly valued in applications requiring high load-bearing capacity and low-speed operations. The high tin content contributes to its superior mechanical properties, making it an ideal choice for various industrial applications.

Chemical Composition of C90810

| Element | Percentage (%) | Function |

|---|

| Cu | Remainder | Base metal, provides ductility and conductivity |

| Sn | 11.00-13.00 | Improves strength, hardness, and wear resistance |

| Pb | 0.25 max | Enhances machinability |

| Zn | 0.30 max | Improves fluidity in casting |

| Fe | 0.15 max | Grain refiner, increases strength |

| P | 0.15-0.80 | Deoxidizer, improves fluidity |

| Ni | 0.50 max | Increases strength and corrosion resistance |

| Al | 0.005 max | Deoxidizer |

| S | 0.05 max | Improves machinability |

| Sb | 0.20 max | Increases hardness |

| Si | 0.005 max | Deoxidizer |

Notes:

- In determining Cu min., Cu may be calculated as Cu + Ni.

- For continuous castings, P shall be 1.5% max.

- Ni value includes Co.

- Cu + sum of named elements, 99.4% min. Single values represent maximums.

Mechanical Properties of C90810

| Property | Value | Unit |

|---|

| Brinell Hardness (500 Kg load) | 95 typical | BHN |

| Machinability Rating | 20 | – |

| Density | 0.323 | lb/in³ at 68 °F (20 °C) |

| Tensile Strength | 40,000 | psi |

| Yield Strength | 20,000 | psi |

| Elongation | 20 | % |

| Modulus of Elasticity | 15 | x 10^6 psi |

Performance at Different Temperatures

| Temperature Range | Performance Characteristics | Recommended Use |

|---|

| Low Temperature (-50°C to 0°C) | Maintains ductility and toughness | Suitable |

| Room Temperature (20°C to 25°C) | Optimal strength and wear resistance | Ideal |

| Elevated Temperature (100°C to 200°C) | Retains strength but may experience slight softening | Acceptable |

| High Temperature (>200°C) | Not recommended for prolonged use | Not Recommended |

Industry Applications

| Industry | Applications | Key Benefits |

|---|

| Industrial Machinery | Bearings, gears, shafts, worm gears | High wear resistance |

| Marine | Pump impellers, valve bodies | Corrosion resistance |

| Construction | Movable bridge components, turntables for bridges | Strength and durability |

| Automotive | Piston rings | Low friction coefficient |

| Energy | Steam fittings | Heat resistance |

| Mining | Heavy-duty bushings | Impact resistance |

| Aerospace | Bushings for landing gear | High load capacity |

| Oil and Gas | Valve components | Corrosion resistance in harsh environments |

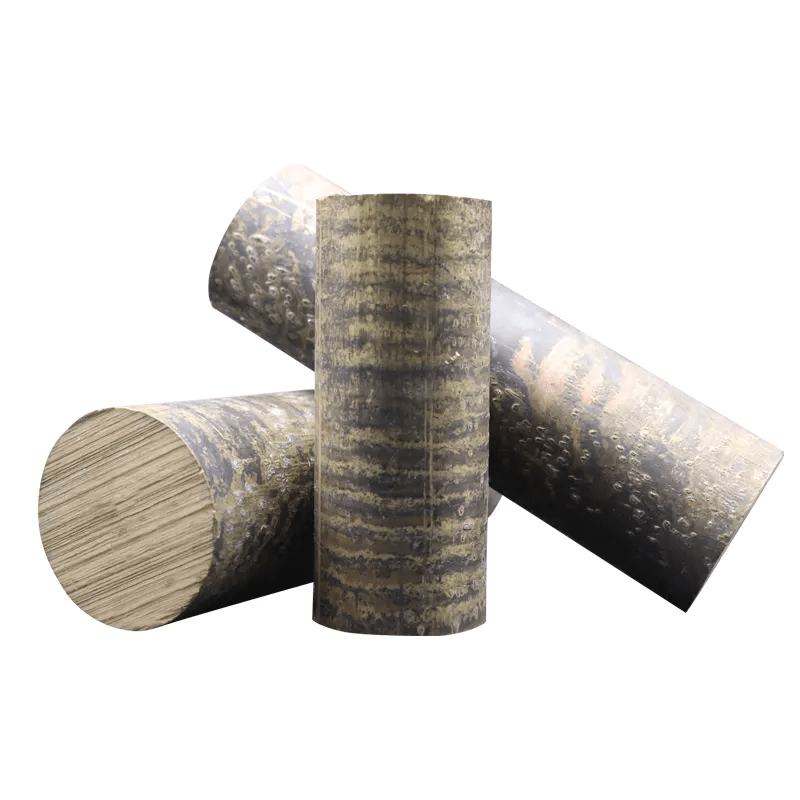

Shape and Size Availability

| Shape | Size Range | Standard Length |

|---|

| Solids | 1″ to 6″ O.D. | 144″ |

| Tubes | 1″ to 6″ O.D. | 144″ |

| Rectangles | Up to 10″ | 144″ |

| Plates | Up to 24″ thickness | 96″ x 240″ |

| Rods | 0.25″ to 12″ diameter | 144″ |

| Custom Shapes | As per requirement | Varies |

Available Forms

| Form | Typical Use | Availability |

|---|

| Semi-finished | Further processing | Common |

| Mill stock | Direct use | Widely available |

| Near-net shapes | Minimal machining | On request |

| Bar stock | Machining | Standard |

| Plate | Large flat components | Common |

| Profile or structural shape | Specific applications | On request |

| Forgings | High-strength components | Limited |

| Castings | Complex shapes | Common |

Production Standards and Compliance

| Standard/Compliance | Region | Relevance |

|---|

| Federal Safe Drinking Water Act – SDWA | USA | Water safety |

| S. 3874 Federal Reduction of Lead in Drinking Water Act | USA | Lead content |

| California AB1953 | California, USA | Lead content |

| Vermont Act 193 | Vermont, USA | Lead content |

| ASTM B505 | International | Continuous Casting of Copper Alloys |

| ASTM B271 | International | Copper-Base Alloy Centrifugal Castings |

| ISO 1338 | International | Cast copper alloys |

| JIS H5111 | Japan | Bronze castings |

Standards and Corresponding Grades in Different Countries

| Country | Standard | Corresponding Grade |

|---|

| USA | UNS | C90810 |

| Germany | DIN | CuSn12 |

| Japan | JIS | CAC704 |

| United Kingdom | BS | HTB1 |

| France | NF | CuSn12 |

| Italy | UNI | CuSn12 |

| Russia | GOST | BrO12 |

| China | GB | ZCuSn12 |

| International | ISO | CuSn12 |

Welding Characteristics

| Welding Method | Suitability | Notes | Preheat Temp |

|---|

| Gas Welding | Good | Use phosphor bronze filler rod | 150-200°C |

| TIG Welding | Excellent | Use pure argon shielding gas | As needed |

| MIG Welding | Good | Use bronze filler wire | As needed |

| Stick Welding | Fair | Use bronze electrodes | As needed |

| Resistance Welding | Poor | Not recommended | N/A |

| Electron Beam Welding | Good | For precision applications | As needed |

| Laser Welding | Fair | Requires careful control | As needed |

Processing Characteristics

| Process | Suitability | Notes | Key Consideration |

|---|

| Machining | Good | Machinability rating of 20 | Tool selection |

| Forming | Fair | Limited formability due to high tin content | Avoid excessive deformation |

| Forging | Poor | Not recommended | N/A |

| Casting | Excellent | Ideal for sand and centrifugal casting | Proper cooling rate |

| Extrusion | Poor | Not typically extruded | N/A |

| Deep Drawing | Poor | Limited ductility | Not recommended |

| Spinning | Fair | Possible with proper techniques | Avoid work hardening |

| Broaching | Good | Suitable for precision sizing | Tool wear |

Polishing Characteristics

| Polishing Method | Result | Recommended Abrasives |

|---|

| Mechanical Polishing | Good surface finish achievable | Alumina or diamond compounds |

| Chemical Polishing | Moderate results | Proprietary solutions |

| Electro-polishing | Excellent for high luster finish | Phosphoric acid-based electrolytes |

| Buffing | High shine possible | Soft cloth wheels with fine abrasive |

| Lapping | Precision finish | Diamond or silicon carbide compounds |

| Honing | Good for cylindrical surfaces | Bonded abrasive stones |

Heat Treatment

| Heat Treatment | Temperature Range | Purpose | Cooling Method |

|---|

| Annealing | 550-650°C | Stress relief and softening | Slow cooling |

| Solution Treatment | Not applicable | C90810 is not heat treatable | N/A |

| Age Hardening | Not applicable | C90810 is not age hardenable | N/A |

| Stress Relieving | 260-370°C | Reduce internal stresses | Air cooling |

| Normalizing | Not typically performed | N/A | N/A |

| Quenching | Not recommended | May cause distortion | N/A |

Cold Processing Characteristics

| Process | Suitability | Notes | Alternative Suggestion |

|---|

| Cold Working | Limited | High tin content reduces ductility | Consider hot working if necessary |

| Cold Drawing | Poor | Not recommended | Use machining instead |

| Cold Rolling | Poor | Not recommended | Consider cast or machined forms |

| Cold Heading | Not suitable | Too brittle | Use machining or casting |

| Cold Forging | Not suitable | Lacks necessary ductility | Consider hot forging or casting |

| Shot Peening | Fair | Can improve surface properties | Use with caution |

Advantages and Disadvantages of C90810

| Advantages | Disadvantages | Considerations |

|---|

| High strength | Limited formability | Design for minimal forming |

| Excellent wear resistance | Higher cost compared to some bronzes | Consider for critical applications |

| Good corrosion resistance | Not suitable for high-speed applications | Use in low to moderate speed settings |

| Low friction coefficient | Limited cold working ability | Design for as-cast or machined forms |

| Suitable for heavy loads | Not heat treatable | Select for applications not requiring heat treatment |

| Good machinability | Relatively high density | Consider weight in design |

| Excellent bearing properties | Susceptible to tin pest at very low temperatures | Avoid prolonged exposure below 13°C |

| Good dimensional stability | Can be difficult to weld | Use appropriate welding techniques |

| Resistant to seawater corrosion | Not as strong as steel | Use in appropriate load conditions |

| Low magnetic permeability | Higher cost than brass | Justify cost with performance requirements |

Similar Products

| Alloy | UNS Number | Main Composition | Key Differences |

|---|

| C90700 | C90700 | Cu-Sn-Zn | Lower tin, higher zinc content |

| C91100 | C91100 | Cu-Sn | Higher tin content, no lead |

| C93200 | C93200 | Cu-Sn-Pb | Higher lead content for improved machinability |

| C95400 | C95400 | Cu-Al-Fe | Aluminum bronze with different property profile |

| C95500 | C95500 | Cu-Al-Ni-Fe | Nickel-aluminum bronze with higher strength |

| C86300 | C86300 | Cu-Mn-Ni-Fe | Manganese bronze with higher strength |

| C92200 | C92200 | Cu-Sn-Pb-Zn | Navy M gun metal with different composition |

Comparison of C90810 with Similar Products

| Property | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| Tensile Strength (psi) | 40,000 | 36,000 | 45,000 | 35,000 | 90,000 |

| Yield Strength (psi) | 20,000 | 18,000 | 25,000 | 18,000 | 45,000 |

| Elongation (%) | 20 | 25 | 15 | 20 | 15 |

| Brinell Hardness | 95 | 70 | 100 | 65 | 190 |

| Corrosion Resistance | Excellent | Good | Excellent | Good | Excellent |

| Machinability | Good | Very Good | Fair | Excellent | Fair |

| Weldability | Fair | Good | Fair | Poor | Good |

| Wear Resistance | Excellent | Good | Excellent | Good | Excellent |

| Cost | High | Moderate | Very High | Moderate | High |

| Typical Applications | Heavy-duty bearings | General-purpose | High-load bearings | Bushings, bearings | Marine components |

Conclusion:

C90810 High Tin Bronze is a specialized alloy that offers a unique combination of properties, making it invaluable in various industrial applications. Its high tin content contributes to excellent strength, wear resistance, and corrosion resistance, particularly in heavy-load, low-speed settings. While it has limitations in formability and high-temperature applications, C90810 excels in industries such as marine engineering, industrial machinery, and construction.

The alloy’s versatility is evident in its wide range of available forms and sizes, adherence to international standards, and good machinability. However, designers and engineers must consider its specific characteristics, such as limited cold working ability and heat treatment options, when incorporating C90810 into their projects.

Compared to similar alloys, C90810 stands out for its balance of strength, wear resistance, and corrosion resistance. Its unique property profile makes it an ideal choice for applications where these characteristics are crucial, justifying its higher cost in critical components.

In summary, C90810 High Tin Bronze continues to be a valuable material in modern engineering, offering reliable performance in demanding environments where other alloys may fall short.