C63020 Bronze description

C63020 is a Nickel Aluminum Bronze alloy known for its excellent mechanical properties and corrosion resistance, suitable for a variety of applications across industries. Here’s a brief overview:

- Composition: Primarily composed of copper (Cu), aluminum (Al), and nickel (Ni), with additions of iron (Fe), manganese (Mn), and other elements.

- Mechanical Properties: Offers high tensile strength, good yield strength, and moderate hardness, making it ideal for components subjected to heavy loads and harsh environments.

- Applications: Commonly used in marine environments for propellers, fittings, and shipbuilding, and in aerospace and industrial sectors for bushings, valve components, bearings, and gears.

- Standards: Complies with ASTM B150/B150M and SAE J461 standards, ensuring consistent quality and performance in various applications.

C63020 Nickel Aluminium Bronze Product Introduction

Chemical Composition

| Element | Composition (%) |

|---|---|

| Copper (Cu) | 87.0 – 90.0 |

| Aluminum (Al) | 4.0 – 5.5 |

| Nickel (Ni) | 4.0 – 5.5 |

| Iron (Fe) | 3.0 – 5.0 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Lead (Pb) | 0.05 max |

| Tin (Sn) | 0.10 max |

| Zinc (Zn) | 0.50 max |

| Others | 0.50 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 690 – 930 MPa |

| Yield Strength (0.2% offset) | 380 – 585 MPa |

| Elongation | 15 – 25% |

| Hardness (Brinell) | 170 – 230 HB |

Performance at Different Temperatures

C63020 Nickel Aluminium Bronze exhibits good mechanical properties and corrosion resistance across various temperatures, suitable for marine and industrial applications.

Industry Applications

C63020 Nickel Aluminium Bronze is used in:

- Marine: propellers, fittings, shipbuilding.

- Aerospace: bushings, valve components.

- Industrial: bearings, gears, pump components.

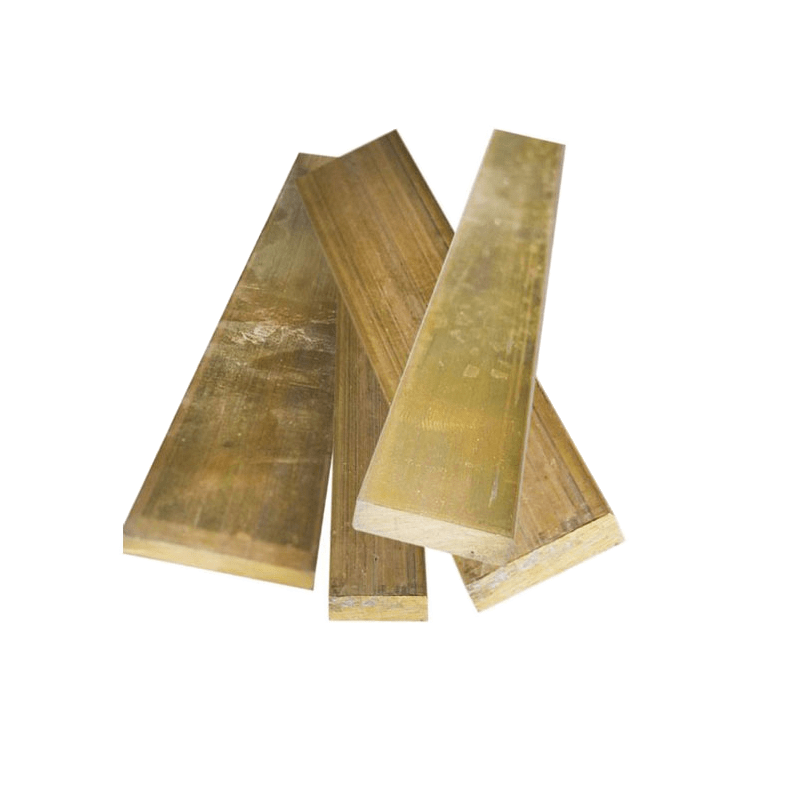

Shape and Size

C63020 Nickel Aluminium Bronze is available in various forms:

- Rods: Diameter ranging from 6 mm to 150 mm.

- Bars: Square and round bars of various dimensions.

- Plates: Thickness ranging from 5 mm to 50 mm.

- Tubes: OD ranging from 10 mm to 200 mm.

Production Standards

C63020 Nickel Aluminium Bronze conforms to international standards such as:

- ASTM B150/B150M: Standard specification for aluminum bronze rod, bar, and shapes.

- SAE J461: Wrought and cast copper alloys.

Standards and Corresponding Grades

| Country/Region | Standards | Corresponding Grades |

|---|---|---|

| USA | ASTM B150/B150M | C63020 |

| Europe | BS EN 12163, BS EN 12420 | CuAl9Ni5Fe4 |

| Japan | JIS H3250 | C6300 |

Welding, Processing, Polishing

C63020 Nickel Aluminium Bronze can be welded using methods suitable for copper alloys. It is machinable and can be polished to a smooth finish.

Heat Treatment and Cold Processing

C63020 Nickel Aluminium Bronze can undergo heat treatment to improve its mechanical properties. Cold working can also enhance its strength.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| High strength and corrosion resistance | Higher cost compared to standard bronze alloys |

| Good wear resistance and machinability | Requires skilled welding and machining |

| Versatile applications in marine and industrial sectors | Limited availability in certain regions |

Similar Products and Comparison

| Alloy Type/Property | C63020 Nickel Aluminium Bronze | C95400 Aluminum Bronze | C62300 Aluminum Bronze |

|---|---|---|---|

| Composition (%) | Cu: 87.0-90.0, Al: 4.0-5.5, Ni: 4.0-5.5 | Cu: 88.0, Al: 10.0 | Cu: 88.0, Al: 10.0 |

| Tensile Strength (MPa) | 690-930 | 500 | 600 |

| Yield Strength (MPa) | 380-585 | 200 | 250 |

| Applications | Marine, aerospace, industrial | Bearings, gears, bushings | Valves, fittings |

Conclusion

C63020 Nickel Aluminium Bronze offers superior mechanical properties and corrosion resistance, making it ideal for demanding applications in marine, aerospace, and industrial sectors. Its composition and performance meet stringent international standards, ensuring reliability and durability in various operational environments.