7075 Aluminum Alloy Product Description:

Conforms to GB/T3880.2–2012 standards for aluminum alloys.ns will find 7075 alloy suitable for its robustness and high-performance capabilities.

Composition: Contains zinc as the primary alloying element, with added magnesium and copper.

Strength: Exceptionally strong with a tensile strength of 524 MPa and yield strength of 455 MPa.

Applications:

Ideal for aircraft frames and high-strength components.

Used in military and aerospace applications.

Suitable for CNC machining due to its machinability.

Properties:

Lightweight yet robust.

Offers good corrosion resistance.

Specifications:

Density ranges from 2.8 to 2.85 g/cm³.

7075 Aluminum Alloy Product Introduction

7075 aluminum alloy is a high-strength aerospace-grade material known for its exceptional mechanical properties, including high strength, toughness, and resistance to stress corrosion cracking. This article provides a comprehensive overview of 7075 alloy, covering its chemical composition, mechanical properties, performance characteristics at different temperatures, industry applications, shapes and sizes, production standards, welding and processing capabilities, advantages and disadvantages, and a comparison with similar alloys.

Chemical Composition

7075 aluminum alloy primarily consists of:

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | Balance |

| Zinc (Zn) | 5.1 – 6.1 |

| Magnesium (Mg) | 2.1 – 2.9 |

| Copper (Cu) | 1.2 – 2.0 |

| Chromium (Cr) | 0.18 – 0.28 |

| Manganese (Mn) | 0.3 max |

| Silicon (Si) | 0.4 max |

| Iron (Fe) | 0.5 max |

| Titanium (Ti) | 0.2 max |

Mechanical Properties

7075 aluminum alloy exhibits impressive mechanical properties suitable for high-performance applications:

| Property | Value |

|---|---|

| Tensile Strength, ksi (MPa) | 74 – 78 (510 – 538) |

| Yield Strength (0.2% offset), ksi (MPa) | 63 – 69 (434 – 503) |

| Elongation (% in 2 inches) | 11 – 13 |

| Hardness, Brinell (HB) | 150 |

Performance Characteristics

7075 aluminum alloy offers several performance advantages:

- High Strength-to-Weight Ratio: Provides high strength comparable to many steel alloys while being lightweight, suitable for aerospace and automotive applications.

- Excellent Fatigue Resistance: Exhibits good fatigue strength, crucial for applications requiring repetitive stress cycles.

- Corrosion Resistance: Offers good corrosion resistance, especially when compared to other aluminum alloys, though not as corrosion-resistant as 2000 or 5000 series alloys.

Industry Applications

7075 aluminum alloy is widely used in industries requiring high strength and lightweight properties:

| Industry Sector | Applications |

|---|---|

| Aerospace | Aircraft structures, fuselage panels, wings, helicopter rotor blades. |

| Automotive | High-performance car parts, including chassis components, wheels, and suspension systems. |

| Military | Missile parts, military aircraft, and armored vehicles requiring strength and durability. |

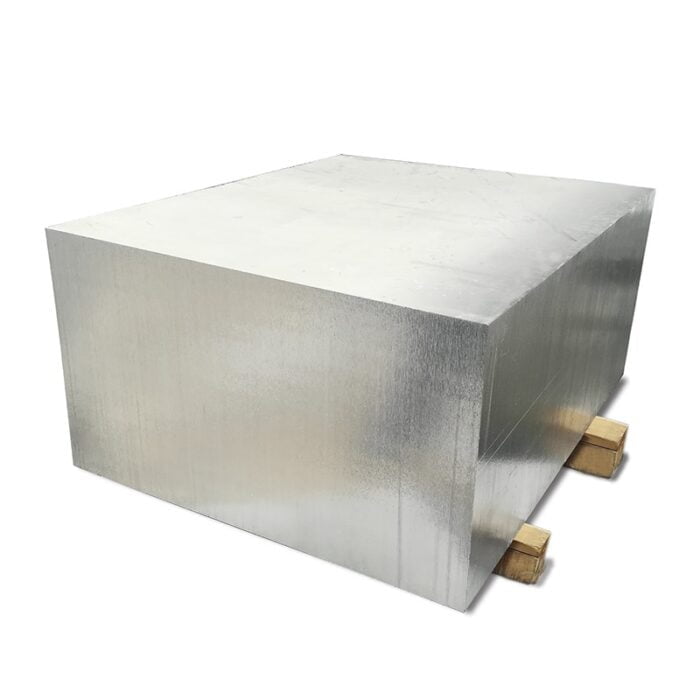

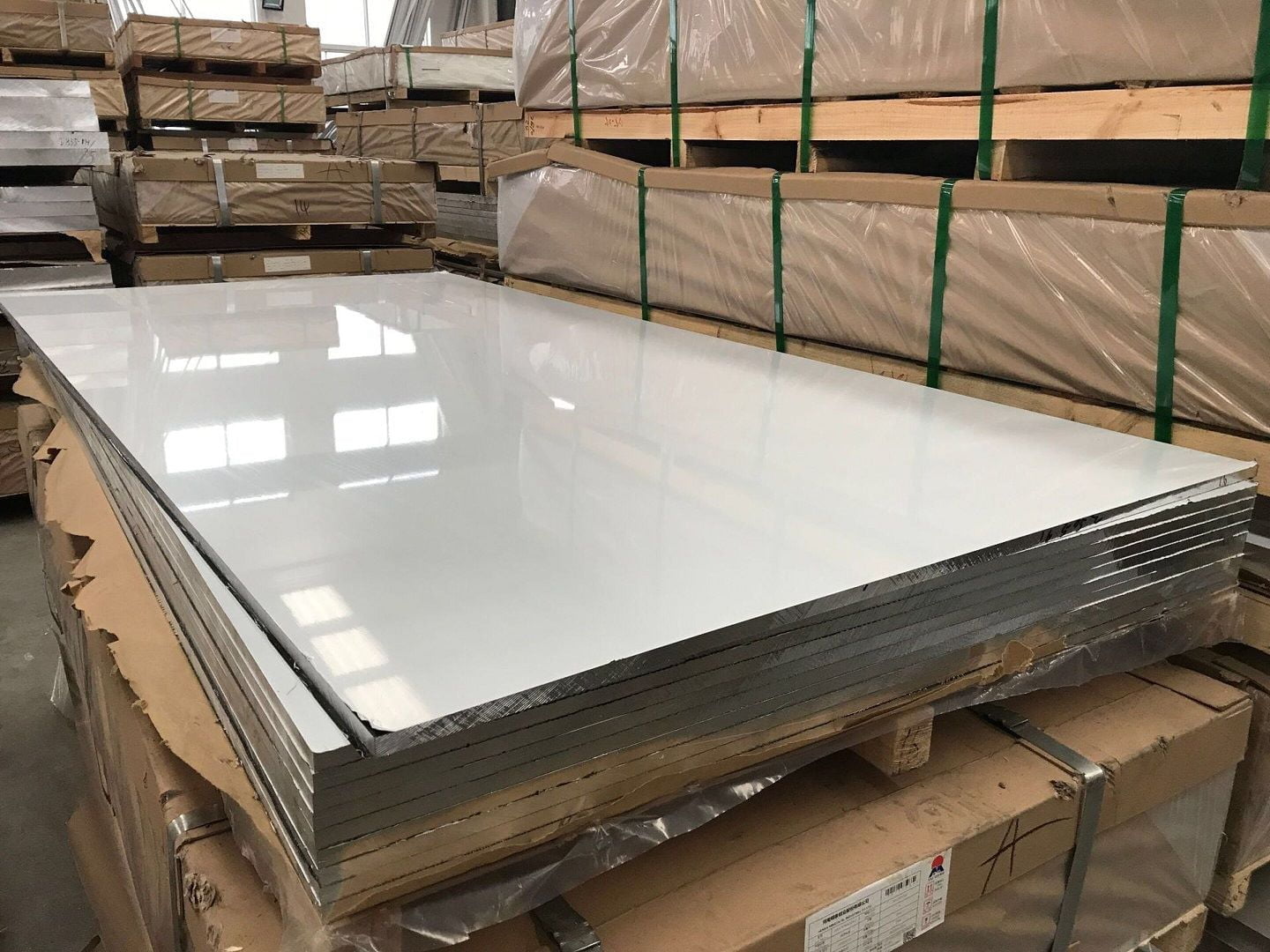

Shapes and Sizes

7075 aluminum alloy is available in various forms and sizes:

- Forms: Sheets, plates, bars, forgings, and extrusions.

- Sizes: Thickness ranging from 0.2 mm to 300 mm for plates, and diameter ranging from 6 mm to 300 mm for round bars.

Production Standards

7075 aluminum alloy conforms to international production standards ensuring quality and reliability:

| Product Form | Shapes Available | Sizes Available | Production Standards |

|---|---|---|---|

| Plates/Sheets | Sheets, Plates | Thickness: 0.2 mm – 300 mm | ASTM B209, AMS QQ-A-250/12 |

| Bars/Rods | Round bars, Square bars | Diameter: 6 mm – 300 mm | ASTM B211, AMS QQ-A-225/9 |

| Extrusions | Custom shapes, profiles | Various sizes | ASTM B221 |

Welding and Processing

7075 aluminum alloy offers good weldability and processing characteristics:

- Welding: Can be welded using conventional methods such as TIG and MIG welding, with proper filler materials and techniques to avoid cracking.

- Machinability: Generally machined in the T6 temper (solution heat treated and artificially aged) using carbide tools and appropriate cutting fluids.

Advantages and Disadvantages

| Aspect | Details |

|---|---|

| Advantages | High strength-to-weight ratio, excellent fatigue resistance, good machinability and weldability, suitable for high-stress applications. |

| Disadvantages | Lower corrosion resistance compared to some other aluminum alloys, higher cost than standard aluminum grades. |

Comparison with Similar Alloys

7075 aluminum alloy is often compared with other high-strength aluminum alloys such as 2024 and 6061. Here’s a brief comparison:

| Alloy Type/Property | 7075 Alloy | 2024 Alloy | 6061 Alloy |

|---|---|---|---|

| Chemical Composition | Higher zinc and magnesium content for improved strength. | Higher copper content for improved machinability. | Lower magnesium and zinc content, silicon and magnesium for strength and corrosion resistance. |

| Mechanical Properties | Higher tensile strength and yield strength, good fatigue resistance. | Moderate strength and good fatigue resistance. | Good balance of strength and corrosion resistance, lower tensile strength compared to 7075. |

| Applications | High-performance aerospace, automotive and military applications. | Aircraft structures, fuselage skins, and truck frames. | Structural components, marine fittings, and automotive parts. |

This detailed article introduces 7075 aluminum alloy, highlighting its chemical composition, mechanical properties, performance characteristics, industry applications, available forms and sizes, production standards, welding and processing capabilities, as well as advantages, disadvantages, and a comparison with similar alloys. Engineers and professionals seeking a lightweight yet strong material for aerospace, automotive, and military applicatio