Japan JFE steel profile

JFE Steel has a history of 90 years and is one of the top 10 steel companies in the world.

Based on its experience, research and development, JFE steel has made unremitting efforts to improve the equipment, increase the variety and enrich the quality management every year to meet the requirements of our customers.

In Japan JFE steel with three of the world’s most advanced medium plate factory, can manufacture 5350 mm wide and 360 mm thick medium plate products, such as high strength steel, wear-resistant steel, low temperature steel plate, boiler, pressure vessel steel plate, nickel high class atmosphere corrosion resisting steel plates, stainless steel plate, all kinds of composite steel plate, etc., more than millions of tons of production.

JFE Wear-resistant steel plate series

- EH-C340, C400, C450, C500, C550

- EH-C400LE, C450LE, C500LE

JFE High strength steel plate series

- HITEN780S, 780LE

- HITEN980S

- HYD960LE

Lion Metal is a leading wholesaler vendor, merchant, and exporter of JFE EH C450 Plates.

We also manufacture all the household stainless steel, high nickel alloys, and carbon steel.

C450 Plates are constructed with chemical composition such as carbon, manganese, chromium, silicon, nickel, molybdenum, boron, sulfur, and phosphorous.

Similar material recommendation: JFE EH C400 Wear Resistant Steel Plate

These plates are also made with mechanical properties such as yield strength, tensile strength, elongation, and longitudinal degrees.C450 plates are made with specifications like material qualities, length, thickness, width, heat treatment, and surface paints.

JFE EH C450 Steel Plates are applicable in many general purposes such as machine-building, construction of the bridges, lifting & mobile equipment, wearing plates, crane booms, rail cars, pylons & other equipment of architectural structures, framework structures, containers manufacturing, vehicles & transport equipment, steel constructors, anti-drill plates such as tumbling machine, shot blasting equipment, and security doors, truck frames, and stone & iron chutes.

EH C450 Plates are useful in mining, transport machinery, stone crusher, loading buckets & bulldozers, dump truck bodies, conveyors, and also useful as material for civil engineering, mining excavator buckets, cement plant industry, industrial fans, farming equipment, sugar factory, fertilizer industry, petroleum & gas industry, paper industry and many more.

Nicrodur C450 Plates are resistant to weld cracks and improve abrasion plates that perform better than C500 plates. The abrasion-resistant level increases without reducing the formability and weldability.

These plates are mostly considered when the toughness of the plate is required in the low-temperature atmospheres. It also has high resistant from the welded joints and weld corrosion cracking.

C450 plates have improved low temperatures harness in harsh cold conditions. These plates have excellent workability and weldability that enable efficient production. These plates are longer sustainable with lightweight and also conserve natural resources. These handy plates are excellent for fabricating the products.

JFE EH C450 Plates go through several tests after the production such as pitting resistance test, intergranular test, corrosion test, chemical test, mechanical test, flattening test, flaring test, hardness test, macro test, micro test, positive material identification test, hydrostatic test, ultrasonic test, radiography test, and many other tests.

We are packing the plates as per the expectations of the clients.

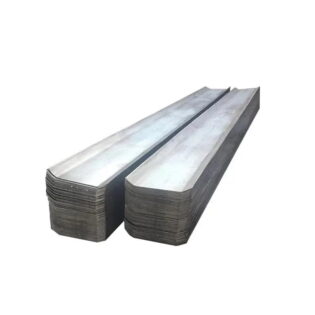

JFE EH C450 Plate Specification :

- Item: Abrasion Resistant Plate

- Thickness : 5 – 50.8, 50.9 – 101.6

- Length : 1,0000mm to 12,000mm

- Width : 500mm to 3000mm

- Surface : Tempering, Quenched, Normalized.

- Certificates : ISO9001:2000

- Production : Hot-Rolled (HR) / Cold-Rolled (CR)

- Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

- Heat treatment : Controlled heat treatment

JFE EH C450 PLATES CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | V | Ti | B | Ceq** |

| JFE EH C450 | 0.25 max. | 0.55 max | 1.60 max. | 0.030 max | 0.030 max | 0.80-1.50 | 0.50 max | – | 0.020 max. | 0.004 max. | – |

JFE EH C450 PLATES MECHANICAL PROPERTIES

| Brand name | Thickness(mm) | Brinell hardness [guaranteed] (29.42 kN) Average of 5 points | Charpy impact properties (2mmV) | Ceq (%)** [guaranteed] | |

| Test temperature [guaranteed] (C°) | Charpy absorbed energy (J) [guaranteed]* | ||||

| EVERHARD-C450 | 5 – 101.6 | 450±25 | – | – | – |

|---|---|---|---|---|---|