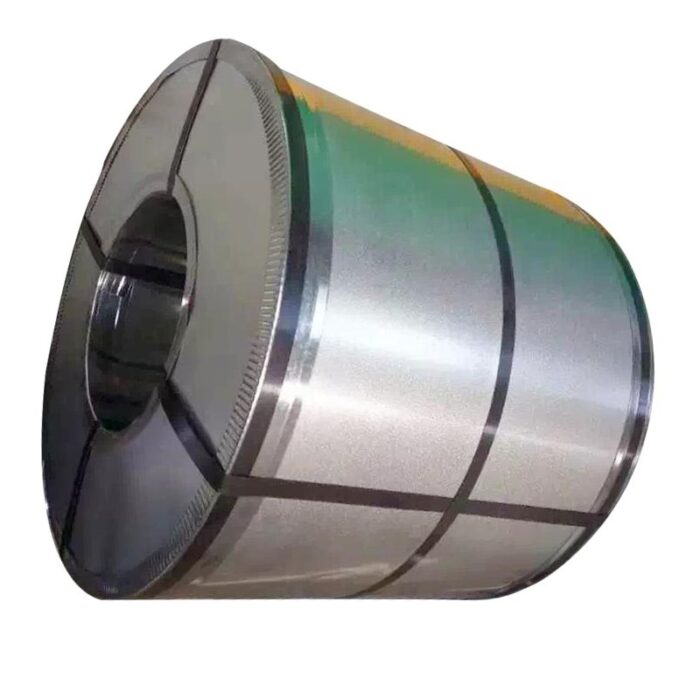

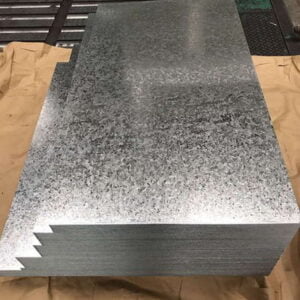

DX51D Galvanized Steel Sheet Description

Galvanized sheet is a steel plate with a layer of zinc on its surface. Galvanizing is often used as an economical and effective rust prevention method. About half of the world’s zinc production is used in this process.

Galvanized sheet is a steel plate with a layer of zinc on its surface. Galvanizing is often used as an economical and effective rust prevention method. About half of the world’s zinc production is used in this process.

- Category: zinc production process

- Function: Anti-rust

- Essence: steel plate coating

- Typical: hot dip galvanized steel plate

DX51D Galvanized Feature

Galvanized steel plate is to prevent corrosion of the steel plate surface to extend its service life, coated with a layer of metal zinc on the surface of the steel plate(SPCC), this coated zinc steel plate is called galvanized sheet.

DX51D Galvanized Classify

According to the production and processing methods, it can be divided into the following categories:

(1) hot dip galvanized steel plate. Dip the sheet steel into a molten zinc bath and make it adhere to a sheet of zinc. At present, the main use of continuous galvanized process production, that is, the roll of steel plate continuous immersion in the melting of zinc plating tank made of galvanized steel plate;

(2) alloyed galvanized steel plate. This kind of steel plate is also made by hot dip, but immediately after the trough, it is heated to about 500℃, so that it produces zinc and iron alloy film. The galvanized sheet has good coating density and weldability;

(3) electric galvanized steel plate. The galvanized steel plate produced by electroplating method has good processability. But the coating is thin, corrosion resistance is not as good as hot dip galvanized sheet;

(4) single-sided plating and double-sided galvanized steel plate. Single-sided galvanized steel, i.e. galvanized on only one side of the product. In welding, coating, anti-rust treatment, processing and other aspects, with better adaptability than double-sided galvanized sheet. In order to overcome the shortcomings of not coated zinc on one side, there is a galvanized sheet coated with thin layer of zinc on the other side, that is, double-sided difference galvanized sheet;

(5) alloy, composite galvanized steel plate. It is made of zinc and other metals such as aluminum, lead, zinc alloy and composite plating into the steel plate. This kind of steel plate has not only excellent rust resistance, but also good coating performance;

In addition to the above five, there are color galvanized steel plate, printing coated galvanized steel plate, polyvinyl chloride laminated galvanized steel plate, etc. But at present the most commonly used is still hot dip galvanized sheet.

Main production plants and importing countries:

(1) Major domestic manufacturers: WISCO, Angang, Baosteel Huangshi, MCC Hengtong, Shougang, Panzhihua Iron & Steel, Handan Iron & Steel, Maanshan Iron & Steel, Fujian Kaijing, etc.;

(2) The main foreign producers are Japan, Germany, Russia, France, Korea and so on.

DX51D Galvanized Size

SIZE | Zinc coating | Material |

0.20*1000*C | 80 | DX51D+Z |

0.25*1000*C | 80 | DX51D+Z |

0.3*1000*C | 80 | DX51D+Z |

0.35*1000*C | 80 | DX51D+Z |

0.4*1000*C | 80 | DX51D+Z |

0.5*1000*C | 80 | S280GD+Z |

0.5*1000*C | 80 | DX51D+Z |

0.58*1000*C | 80 | S350GD+Z |

0.6*1000*C | 80 | DX51D+Z |

0.7*1000*C | 80 | DX51D+Z |

0.75*1000*C | 80 | DX51D+Z |

0.8*1000*C | 80 | DX51D+Z |

0.8*1000*C | 80 | DX53D+Z |

0.85*1000*C | 80 | DX51D+Z |

0.9*1000*C | 80 | DX51D+Z |

0.98*1000*C | 80 | DX51D+Z |

0.95*1000*C | 80 | DX51D+Z |

1.0*1000*C | 80 | DX51D+Z |

1.1*1000*C | 80 | DX51D+Z |

1.2*1000*C | 80 | DX51D+Z |

1.2*1050*C | 150 | CSB |

1.4*1000*C | 80 | DX51D+Z |

SIZE | Zinc coating | Material |

1.5*1000*C | 80 | DX51D+Z |

1.55*1000*C | 180 | S280GD+Z |

1.55*1000*C | 180 | S350GD+Z |

1.6*1000*C | 80 | DX51D+Z |

1.8*1000*C | 80 | DX51D+Z |

1.9*1000*C | 80 | DX51D+Z |

1.95*1000*C | 180 | S350GD |

1.98*1000*C | 80 | DX51D+Z |

1.95*1000*C | 180 | S320GD+Z |

1.95*1000*C | 180 | S280GD+Z |

1.95*1000*C | 275 | S350GD+Z |

2.0*1000*C | 80 | DX51D+Z |

SIZE | Zinc coating | Material |

0.36*1250*C | 80 | |

0.4*1250*C | 80 | DX51D+Z |

0.42*1250*C | 80 | DX51D+Z |

0.45*1250*C | 225 | S280GD+Z |

0.47*1250*C | 225 | S280GD+Z |

0.5*1250*C | 80 | SGCC |

0.55*1250*C | 180 | S280GD+Z |

0.55*1250*C | 225 | S280GD+Z |

0.6*1250*C | 80 | DX51D+Z |

0.65*1250*C | 180 | DX51D+Z |

0.7*1250*C | 80 | DX51D+Z |

0.7*1250*C | 80 | SGCC |

0.75*1250*C | 80 | DX51D+Z |

0.8*1250*C | 80 | DX51D+Z |

0.9*1250*C | 80 | DX51D+Z |

0.95*1250*C | 80 | DX51D+Z |

SIZE | Zinc coating | Material |

1.0*1250*C | 80 | DX51D+Z |

1.15*1250*C | 80 | DX51D+Z |

1.1*1250*C | 80 | DX51D+Z |

1.2*1250*C | 80 | DX51D+Z |

1.35*1250*C | 80 | DX51D+Z |

1.4*1250*C | 80 | DX51D+Z |

1.5*1250*C | 80 | DX51D+Z |

1.55*1250*C | 80 | DX51D+Z |

1.6*1250*C | 120 | SGCC |

1.6*1250*C | 80 | DX51D+Z |

1.8*1250*C | 80 | DX51D+Z |

1.85*1250*C | 90 | DX51D+Z |

1.95*1250*C | 80 | DX51D+Z |

1.75*1250*C | 80 | DX51D+Z |

2.0*1250*C | 80 | DX51D+Z |

2.0*1250*C | 120 | SGCC |

2.5*1250*C | 80 | DX51D+Z |

The recommended standard thickness, length and width of galvanized sheet and its allowable deviation are listed in the relevant product standards. In general, the thicker the galvanized sheet allows the greater the error, rather than fixed 0.02-0.04 mm, the thickness of the deviation according to the yield, tensile coefficient and other different and have different requirements, the length and width deviation is generally in 5mm, the thickness of the sheet is generally between 0.4-3.2.

DX51D Galvanized Surface

(1) the surface state: galvanized sheet due to different treatment methods in the plating process, the surface state is also different, such as ordinary zinc flower, fine zinc flower, flat zinc flower, no zinc flower and phosphating treatment of the surface. The German standard also provides for surface grades.

(2) galvanized sheet should have a good appearance, no harmful defects to the use of the product, such as no plating, holes, rupture and scum, more than plating thickness, abrasion, chromic acid dirt, white rust, etc. Foreign standards are not very clear on the specific appearance defects. When ordering, the specific defects should be specified in the contract.

DX51D Galvanized Mass of Zn coat

Galvanization standard value: Galvanization is a widely used effective method to indicate the thickness of zinc layer of galvanized sheet. The unit of galvanizing quantity is g/m2. Japan, the United States and Germany standards on galvanized sheet steel galvanized provisions detailed as follows.

Mechanical Property

(1) tensile test:

- Performance indicators: in general, only structural, tensile and deep drawing galvanized sheet has tensile performance requirements. The structural galvanized sheet requires yield point, tensile strength and elongation, etc. For stretching only the elongation is required. See product standards in Section 8 for specific values;

- Test method: The test method is the same as the general thin steel sheet test method, see the relevant standard provided by “8” and the test method standard listed in “ordinary carbon steel sheet”.

(2) Bending test:

- Bending test is the main item to measure the process performance of sheet metal, but the requirements of all kinds of galvanized sheet are not consistent in the national standards, the American standards do not require bending and tensile test except for the structure grade. In Japan, bending tests are required except for structural level, building corrugated plates and general corrugated plates.

- Requirements: general requirements galvanized sheet bending 180, the outer surface shall not be separated from the zinc layer, the substrate shall not be cracked and fracture.

Chemical Component

The requirements of the chemical composition of galvanized sheet substrate, national standards are different, the national standard is generally the detection of carbon, manganese, phosphorus, sulfur, silicon content.

Packaging

It is divided into two kinds: galvanized sheet cut into fixed length and galvanized sheet packing with coil. Generally packed in iron sheet, lined with moisture-proof paper, tied on the bracket with iron kidneys. Strapping should be firm in order to prevent the inner galvanized sheet from rubbing against each other.

Standard

Product standards

JIS-G3302-94 galvanized steel plate;

JIS-G3312-94 Colored galvanized iron sheet;

JIS-G3313 — 90 (96) galvanized steel sheet and strip; General requirements for hot dip galvanized sheet steel;

ASTM A526-90 Commercial Grade Hot Dip Galvanized Steel Sheet;

ASTMA 527 — 90 (75) Hot-dip Galvanized Steel Sheet, Occlusal Form Grade;

ASTMA528-90 Deep Drawing Hot Dip Galvanized Steel Sheet; Hot dip galvanized sheet steel for roofing and paneling;

ASTMA444-89 Hot dip galvanized steel sheet for ditches;

ASTM A446 — 93 Hot dip galvanized steel sheet with structural grade;

ASTMA599 — 92 Cold Rolled Galvanized Steel Sheet;

Hot dip galvanized special deoxidized deep drawing sheet steel;

ΓOCT7118 — 78 galvanized sheet steel;

DINEN10142-91 Part 1 Hot dip galvanized steel strip and sheet steel of low carbon steel;

DINEN1012-92 Part 2 Hot dip galvanized steel sheet.

Test standard

JIS H0401-83 Test method for hot dip galvanizing;

DIN 50952-69 Test method for hot dip galvanizing.

Weight Calculation

Galvated sheet calculation formula: M=7.85* length * width * height + zinc layer calculation weight (look up the table)

(density of steel = 7.85g /cm3)