M2 High Speed Tool Steels Description

M2 is molybdenum high speed steel, which has the advantages of low carbide inhomogeneity and high toughness. It is easy to overheat, so the quenching heating temperature should be strictly controlled and the heat treatment protection is strictly required.

- Hardening temperature: 1220-1240

- Factory hardness ≤255HB

- Hardness ≤63

M2 High Speed Tool Steels

AISI M2 Tool Steel is molybdenum based high-speed steel in tungsten–molybdenum series. HSS grade steel M2 is a medium alloyed high speed steel which has good machinability. The H-SS M2 chemical composition gives a good combination of well-balanced toughness, wear resistance and red hardness properties. Widely used for cutting tools such as twist drills, taps, milling cutters, saws, knives etc. Also commonly used in cold work punches and dies and cutting applications involving high speed and light cuts.

Grade M2 High Speed Steel is by far the most popular high speed steel replacing high speed steel grade T1 in most applications because of its superior properties and relative economy.

We are one of leading AISI M2 HSS steel supplier and we can offer better quality and M2 alloy steel price for your various applications.

1. Supply Range of M2 tool steel High Speed

M2 Steel Round Bar: diameter 2mm – 200mm

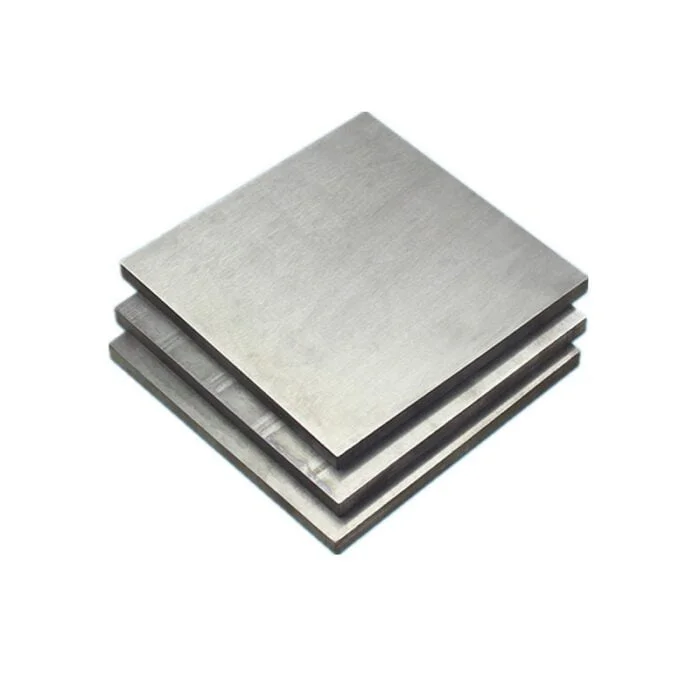

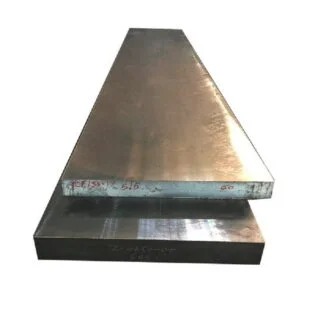

HSS M2 Steel Flat: thickness 2-20mm x width 10-100mm

Steel Plate: thickness 2-200mm x width 200-610mm

Surface Finish: Black, Rough Machined, Turned or as per given requirements.

2. Common M2 Tool Steel Related Specifications and Equivalents

| Country | USA | German | Japan |

| Standard | ASTM A600 | DIN EN ISO 4957 | JIS G4403 |

| Grades | M2 | 1.3343 | SKH51 |

3. ASTM M2 Tool Steel Chemical Composition Properties

| ASTM A600 | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| M2 regular C | 0.78 | 0.88 | 0.15 | 0.40 | 0.03 | 0.03 | 0.20 | 0.45 | 3.75 | 4.50 | 1.75 | 2.20 | 4.50 | 5.50 | 5.50 | 6.75 |

| DIN ISO 4957 | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| 1.3343 | 0.86 | 0.94 | … | … | … | … | … | 0.45 | 3.80 | 4.50 | 1.70 | 2.10 | 4.70 | 5.20 | 5.90 | 6.70 |

| JIS G4403 | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| SKH51 | 0.80 | 0.88 | … | 0.40 | 0.03 | 0.03 | … | 0.45 | 3.80 | 4.50 | 1.70 | 2.10 | 4.70 | 5.20 | 5.90 | 6.70 |

4. AISI HSS M2 Tool Steel Mechanical Properties

- Physical Properties

| Density | 0.294 lb/in3 (8138 kg/m3) |

| Specific Gravity | 8.15 |

| Modulus of Elasticity | 0.294 lb/in3 (8138 kg/m3) |

| Thermal conductivity | 24 Btu/ft/hr/°F 41.5 W/m/°K |

| Machinability | 65% of a 1% carbon steel |

- AISI M2 Tool Steels Properties Mechanical

| Mechanical properties | Metric | Imperial |

| Hardness, Rockwell C (tempered at 1150°F, quenched at 2200°F) | 62 | 62 |

| Hardness, Rockwell C (as hardened, quenched at 2200°F) | 65 | 65 |

| Compressive yield strength (when tempered at 300°F) | 3250 MPa | 471000 psi |

| Izod impact unnotched (when tempered at 300°F) | 67 J | 49.4 ft-lb |

| Abrasion (loss in mm3, as-hardened; ASTM G65) | 25.8 | 25.8 |

| Abrasion (loss in mm3, tempered at 1275°F; ASTM G65) | 77.7 | 77.7 |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

- M2 Steels Thermal Properties

| Thermal properties | Metric | Imperial |

| CTE, linear (@20.0 – 100°C/ 68.0 – 212°F) | 10 μm/m°C | 5.56 μin/in°F |

| CTE, linear (@20.0 – 500°C/68.0 – 932°F) | 12.2 μm/m°C | 6.78 μin/in°F |

| CTE, linear (@20.0 – 850°C/68.0 – 1560°F) | 12.6 μm/m°C | 7 μin/in°F |

5. Forging of AISI M2 High Speed Steel

Pre heat M2 HSS steel slowly and uniformly to 850-900°C. The heat should then be increased more quickly to the forging temperature of 1050-1150°C. If during the forging the temperature of the M2 high speed tool steel material drops below 880-900°C, re-heating will be necessary. Cool the M2 steel component very slowly after forging.

6. Heat Treatment of M2 Steel HSS

- Anneal

Heat to 1600°F, soak thoroughly at heat. Furnace cool 25°F per hour to 900°F, air cool to room temperature. Approximate annealed hardness 241 Maximum Brinell.

Stress Relief of Unhardened Material: Heat slowly to 1200 to 1250°F. Soak for two hours per inch of thickness at heat. Slow cool (furnace cool if possible) to room temperature.

- Harden

Heat slowly to 1550°F, soak thoroughly, heat to 1850°F, soak thoroughly. Soak time in the furnace varies from a few minutes to 15 minutes, depending tool size, heat capacity of the furnace, and the size of the charge. – Heat to 2150 to 2200° F for max. toughness and minimum distortion. – Heat to 2250 to 2275°F for max. hardness and abrasion resistance.

- Quench

For full hardness, oil quench to 150-200°F. Air quench to 150°F. When quenching in hot salt maintain the quench just above the Ms temperature. After equalizing withdraw parts from the hot salt and air cooled to 150°F.

- Temper

Double temper is mandatory, three tempers are sometimes preferred. Soak for 2 hours per inch of thickness. Air cool to room temperature between tempers. The best tempering range for hardness, strength and toughness is 1000 to 1050°F.

| Temper°F | Rockwell “C” | Temper° F | Rockwell “C” |

| As-quenched | 64 | 900 | 64 |

| 400 | 63 | 1000 | 65.5 |

| 500 | 62.5 | 1050 | 63.5 |

| 600 | 62.5 | 1100 | 61.5 |

| 700 | 62.5 | 1150 | 60 |

| 800 | 63.5 | 1200 | 53 |

7. Machinability of AISI M2 Tool Steel H-SS

Shaping can be carried out using grinding methods. However, they have poor grinding capability and hence they are regarded as “medium” machinability tool steel under annealed conditions. The machinability of these tool steels is only 50% of that of the easily machinable W group or water hardening tool steels.

8. Tool Steel Applications

The main use of high-speed steels continues to be in the manufacture of various cutting tools.

Typical applications for M2 high speed steel are twist drills, reamers, broaching tools, taps, milling tools, metal saws. M2 is suitable for cold forming tools such as extrusion rams and dies, also widely used in all kinds of cutting tools, knife and punches and die applications, plastic moulds with elevated wear resistance and screws.