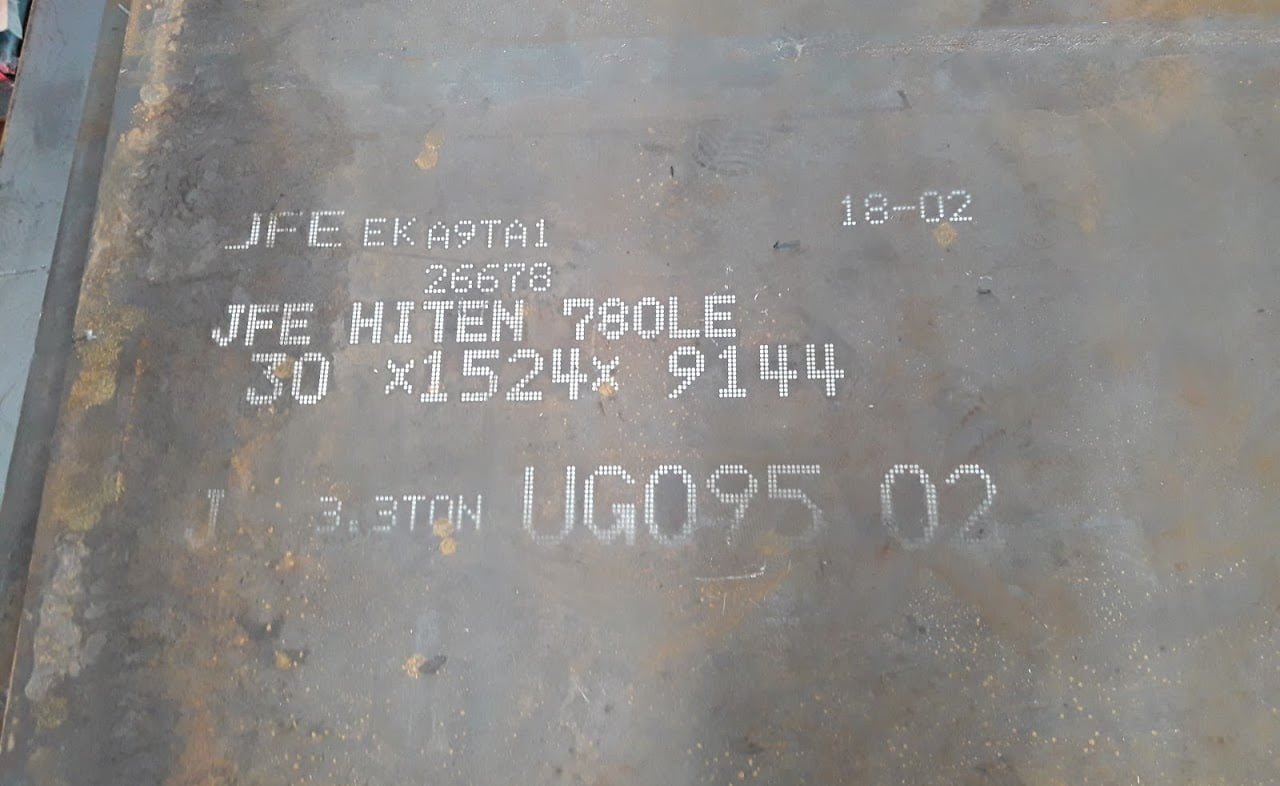

Opis JFE HITEN 780LE

HITEN 780LE are made by utilizing heading advances including controlled moving and least micro-alloying, subsequently, giving great weldability and high sturdiness over in low temperature (-40°c) locales.

Hiten 780LE is produced in thickness up to 50mm thick with alloying elements reduced to a minimum. Following the conventional welding methods and using low hydrogen consumables and not requiring preheat makes this particular grade of steel highly suited for use in mining, construction and industrial equipment.

Specyfikacja blachy stalowej Hiten 780LE

| Stopień | Płyta JFE Hiten 780Le |

|---|---|

| Grubość | 12-60 mm |

| Szerokość | 1500 mm do 2500 mm |

| Długość | 6000mm-128000mm |

| Klasyfikacja | Wyroby walcowane na gorąco ze stali konstrukcyjnych |

Our products undergo various destructive and non-destructive tests for attributes like hardness, material chemical composition, and many more. We provide a comprehensive range of plates that is inspected under high-quality checks to ensure error-free operations.

JFE HITEN 780LE plates have many good qualities like high tensile strength, excellent weldability, good uniformity, and clean surface and good notch toughness. We have ready stock available in different size ranges that can cater to our clients in case of emergency.

Why choose the Lion metal purchase JFE-HITEN-780LE

At Lion Metal, each JFE HITEN 780LE plates, are adequately packed by using standard packaging methods to avoid damage during the transit. Customize packaging is also done as per the customer’s standards to provide the damage free delivery of products.

Our quality team takes ownership to maintain the quality from end to end stages of products from manufacturing until it reaches customers. All the essential documents and reports are provided to our valuable patrons at the time of product delivery.

We make use of the convenient mode of transportation to ensure the fastest delivery on time.

We make sure that JFE HITEN 780LE are safely delivered to our clients in different parts of the world on time.

780LE JFE Hiten Steel Plates Equivalent Grades

| JFE Standard | ASTM | JIS | WES |

|---|---|---|---|

| JFE-HITEN 780LE | A514 A709 Gr.100 | G3128 SHY685 SHY685N SHY685NS | HW 685 |

EN 10025 JFE HITEN 780LE Plates Specifications

Grubość: 6mm to 100mm

Szerokość : 1500 mm do 2500 mm

Długość : 3000mm -18000mm

Produkcja : Walcowane na gorąco (HR) / Walcowane na zimno (CR)

Heat Treatment : N, Q+T

Surface Paint : EP, PE, HDP, SMP, PVDF

JFE HITEN Plate Grades PDF

| Wytrzymałość (N/mm2) | Przeznaczenie | Grubość (mm) | Yield Strength Min. (N/mm2) | Wytrzymałość na rozciąganie (N/mm2) | Features and Typical Applications |

|---|---|---|---|---|---|

| 590 | JFE-HITEN590 JFE-HITEN610 JFE-HITEN570U2 JFE-HITEN590U2 JFE-HITEN610U2 JFE-HITEN570E JFE-HITEN590E JFE-HITEN610E | 6 – 150 6 – 150 6 – 100 6 – 75 6 – 75 6 – 100 6 – 75 6 – 75 | 450 490 450 450 490 450 450 490 | 590 – 710 610 – 730 570 – 700 590 – 710 610 – 730 570 – 700 590 – 710 610 – 730 | For Bridges, Penstocks, Tanks, Offshore structures U2 : High Tensile Strength Steel Plates with High Weldability E : High Tensile Strength Steel Plates with High Weldability for High Heat Input Welding |

| JFE-HITEN590S JFE-HITEN590SL | 6 – 40 6 – 50 | 450 450 | 590 – 710 590 – 710 | S : Without Heat treatment for Civil Engineering and Industrial Machinery SL : Same as above with excellent toughness at low temperature (-40°C) | |

| 690 | JFE-HITEN690 JFE-HITEN710 | 6 – 100 6 – 100 | 590 620 | 690 – 820 710 – 840 | Ni-free type for Tanks, Offshore Structures etc. |

| JFE-HITEN690M JFE-HITEN710M | 6 – 100 6 – 100 | 590 620 | 690 – 820 710 – 840 | Ni type and Low carbon-equivalent for Bridges, Penstocks, Tanks, etc. | |

| JFE-HITEN690S | 6 – 25 | 550 | 690 – 830 | With reducing alloying elements and without Heat Treatment, for Civil Engineering and Industrial Machinery | |

| 780 | JFE-HITEN780M | 6 – 150 | 685 | 780 – 930 | Ni type and Low Carbon-equivalent for Bridges, Penstocks, Offshore structures etc. |

| JFE-HITEN780EX | 6 – 60 | 685 | 780 – 930 | High Performance with Relaxing Pre-heating for Bridges | |

| JFE-HITEN780S | 5 – 160 | 685 | 780 – 930 | Reducing alloying elements for Civil Engineering and Industrial Machinery | |

| JFE-HITEN780LE | 5 – 160 160.1 – 203.2 | 685 610 | 780 – 930 700 – 850 | High Weldability and excellent toughness at low temperature (-40°C), for Civil Engineering and Industrial Machinery | |

| 980 | JFE-HITEN980 | 6 – 120 | 885 | 950 – 1130 | High Strength, High Weldability and Good Toughness for Penstocks |

| JFE-HITEN980S | 5 – 50.8 | 885 | 950 – 1130 | For Civil Engineering and Industrial Machinery | |

| JFE-HITEN980LE | 5 – 50.8 | 900 | 980 – 1150 | High tensile strength steel plate with excellent low temperature toughness (-40°C) for Civil Machinery and Industrial Machinery. | |

| JFE–HYD960LE | 5 – 50.8 50.9 – 63.5 | 960 930 | 980 – 1150 950 – 1120 | Higher yield strength than conventional 980 grade steel, high weldability and excellent toughness at low temperature (-40°C), for Civil Engineering and Industrial Machinery. | |

| 1180 | JFE–HYD1100LE | 12 – 32 | 1100 | 1180 – 1500 | High tensile strength steel plate for Civil Machinery and Industrial Machinery. Has high yield stress, and excellent weldability and low temperature toughness (-40°C). |

Chemical Composition of JFE HITEN 780LE High Strength Steel Plates

| C | ≤0,20 |

|---|---|

| B | .≤0.005 |

| Mn | 1,60 maks |

| Ceq* | ≤0.40 1)** |

| Inni | Nb,V,Ti and others are added if necessary |

Mechanical Properties Of JFE HITEN 780LE Plates & Sheets

| Grubość (mm) | Yield Strength Min. (N/mm 2) | Tensile Strength (N/mm 2) | Cechy |

|---|---|---|---|

| 6 ~ 32 | 685 | 780 ~ 930 | High Weldability and excellent toughness at low temperature (-40 C), for Civil Engineering and Industrial Machiner |

JFE HITEN 780LE Plates Application Industries

Our JFE HITEN 780LE Steel Plates are used in a wide range of applications and various industries. Below are a few of them:

- Conveyor Buckets

- Drag line Bucket Wear Liners

- Dump Truck Liners

- Cutting Edges

- Crusher Liner Plates

- Screen Plates – Chute Liners

- Ripper Tyne

- Loading Buckets

- Bulldozers

- Hoppers