Stop NIMONIC 81

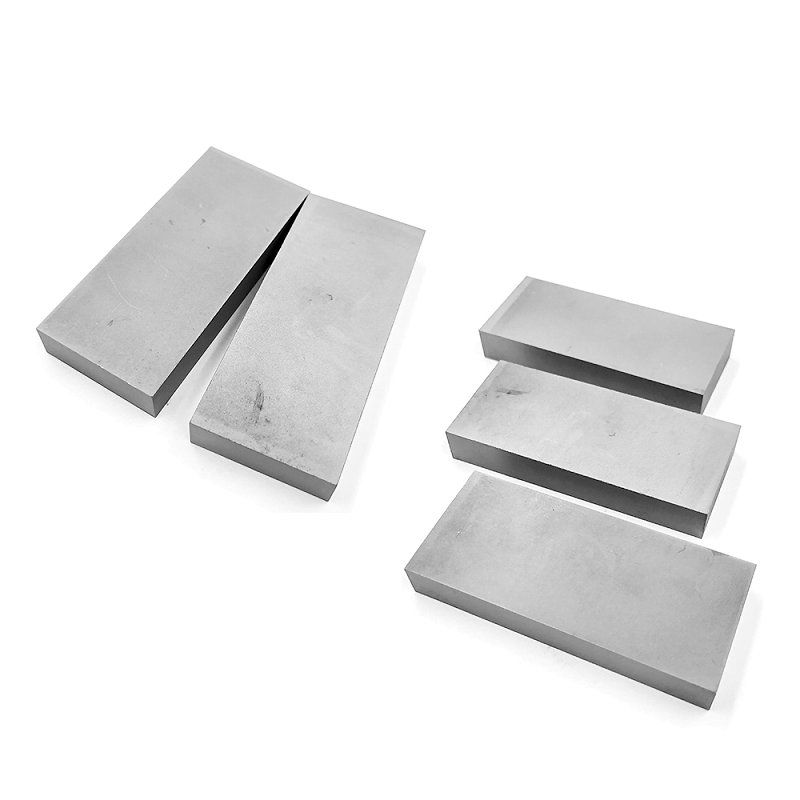

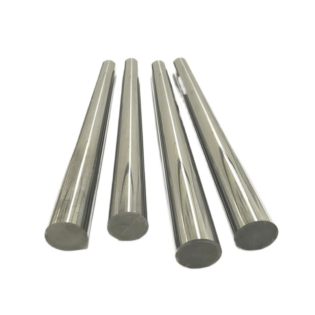

Możemy wyprodukować pręty okrągłe ze stali nierdzewnej ze stopu NIMONIC 81, kucie, blachę, cewkę i taśmę profilowaną ze stopu NIMONIC 81, stal zdeformowaną, stal płaską, formę, drut stalowy, mają wszystkie specyfikacje. Dzięki doświadczeniu produkcyjnemu firmy DuoNian, ścisłej kontroli składu chemicznego stopu NIMONIC 81 i właściwości mechanicznych stopu NIMONIC 81. Od odlewania, kucia, stali po proces walcowania na gorąco i na zimno, obróbkę cieplną itp., mamy kontrolę profesjonalnych inżynierów. Posiadamy zaawansowany sprzęt do precyzyjnej obróbki, zgodnie z wymaganiami użytkowników obróbki. w celu osiągnięcia jak największej satysfakcji z wymagań użytkownika.

Nimonic® 81 Specyfikacja produkcyjna

- Pręt okrągły ze stali: od 1 mm do 3500 mm

- Stal kwadratowa: od 1 mm do 4000 mm

- Płyta stalowa: od 0,1 mm do 4000 mm

- Szerokość: 10 mm do 2500 mm

Długość: Możemy dostarczyć dowolną długość w oparciu o wymagania klienta.

Kucie: Wały z bokami / rurami / rurami / ślimakami / pączkami / kostkami / innymi kształtami

Rury: OD: φ6-1800 mm, z grubością ściany od 1-35 mm.

Stan towarów gotowych: gorący kucie/zwijanie gorącego + wyżarzanie/normalizacja + temperowanie/hartowanie + temperowanie/wszelkie warunki w oparciu o wymagania klienta

Warunki powierzchniowe: skalowane (wykończenie działające na gorąco)/uziemienie/szorstka obróbka/drobna obróbka/na podstawie wymagań klienta

Piece do przetwarzania metalurgicznego: Elektrodę ARC + LF/VD/VOD/ESR/Vacuum Consumowal Electrod.

Kontrola ultradźwiękowa: 100% kontrola ultradźwiękowa pod kątem wszelkich wymagań klienta dla wszystkich branż, z zaletami technologii, sprzętu i ceny.

Służymy wam z naszą uczciwością, uczciwością i profesjonalnością.

Nimonic 81 (Nimonic® 81) Superalloy na bazie niklu

Nimonic® 81 i Nimonic 81 to stwardniały stop z kutego niklu przez kontrolowane dodatki tytanu i glinu, i zaprojektowane w celu zapewnienia zwiększonej odporności na korozję wysokiej temperatury połączoną z dobrą wytrzymałością wysokiej temperatury. Ma doskonałą oporność na gorącą korozję ze względu na wysoką zawartość chromu.

Podwyższona charakterystyka wytrzymałości temperatury jest podobna do charakteru Stop NIMONIC 80A. Praktyki topnienia, gorące, zimne i obróbki są również zasadniczo podobne do tych Stop NIMONIC 80A. Zastosowania obejmują komponenty turbin gazowych, zawory wydechowe silnika tłokowego i roślinę wymiany ciepła podlegające atakom osadów wynikających z spalania nieczystej paliw, szczególnie przez siarczany metalowe i chlorki alkaliczne.

Nimonic 81 (Nimonic® 81) jest zwykle stosowany w stanie traktowanym roztwem i opadami. To obróbka cieplna jest zwykle przeprowadzana w powietrzu. Materiał jest zwykle dostarczany w stanie leczonym rozwiązaniem i jest starzejący się przez klienta w ramach procesu wytwarzania. Zmian nimoniczny 81 może być jednak dostarczany do wszelkich wymaganych warunków obróbki cieplnej. Szczegóły zalecanych obróbki cieplnej dla różnych form podano poniżej, w których podane czasy reprezentują czasy w temperaturze. Ustanawiając, że należy oczywiście, należy oczywiście uzyskać charakterystykę pieca i wagę ładowania.

Nimonic 81 Właściwości mechaniczne:

| Materiał | Ostateczna wytrzymałość na rozciąganie (MPA) | 0.2 % granica plastyczności (MPA) | % Wydłużenie |

|---|---|---|---|

| Nimonic 81 | 874 | 565 | 14 |

Skład chemiczny Nimonic® 81:

| Element | Treść (%) |

|---|---|

| Nikiel, Ni | 63 |

| Chrom, Kr | ≤30 |

| Kobalt, Co | ≤2 |

| Tytan, Ti | 1.8 |

| Żelazo, Fe | ≤1,0 |

| aluminium, al | 0.9 |

| Inni | Reszta |

Nimonic® 81 Właściwości fizyczne:

| Nieruchomości | Metryczny | Cesarski |

|---|---|---|

| Gęstość | 8.06 GM / CM3 | 0.291 LB/in3 |

Nimonic® 81 Oczyszczanie cieplne:

Nimonic® 81 Hot Working

Stop Nimonic 81 może być gorący w zakresie temperatur 950-1160 ° C (1742-2120 ° F).

Kucie Nimonic® 81

Stop Nimonic 81 może być gorący w temperaturach w zakresie 1010-1176 ° C (1850-2150 ° F).

Nimonic® 81 Cold Working

Zimno można wykonać na stopie do stwardnienia.

Nimonic® 81 Eneraling

Stop Nimonic 81 powinien być wyżarzany w 1098 ° C (2010 ° F) przez około 8 godzin.

Zastosowania Nimonic® 81

- Roślina wymiany ciepła.

- Inżynieria turbin gazowych

- Zawory wydechowe silnika tłokowego