Wprowadzenie produktu:

C90810 High Tin Bronze to stop na bazie miedzi znany z wyjątkowej wytrzymałości, odporności na zużycie i odporności na korozję. Ten stop jest szczególnie ceniony w aplikacjach wymagających wysokiej pojemności obciążenia i operacji o niskiej prędkości. Wysoka zawartość cyny przyczynia się do doskonałych właściwości mechanicznych, co czyni ją idealnym wyborem do różnych zastosowań przemysłowych.

Skład chemiczny C90810

| Element | Procent (%) | Funkcjonować |

|---|

| Cu | Reszta | Metal nieszlachetny zapewnia ciągliwość i przewodność |

| Sn | 11.00-13.00 | Poprawia siłę, twardość i odporność na zużycie |

| Pb | 00,25 maks | Zwiększa maszyna |

| Zn | 00,30 maks | Poprawia płynność w odlewie |

| Fe | 00,15 maks | Rozdrabniacz ziarna, zwiększa wytrzymałość |

| P | 0.15-0.80 | Odtleniacz, poprawia płynność |

| W | 00,50 maks | Zwiększa wytrzymałość i odporność na korozję |

| Glin | 00,005 maks | Odtleniacz |

| S | 00,05 maks | Poprawia obrabialność |

| Sb | 00,20 maks | Zwiększa twardość |

| I | 00,005 maks | Odtleniacz |

Uwagi:

- W decydującym cu min. CUCK z obliczeniem i Cu + ni.

- W przypadku odlewań ciągłych P powinien wynosić 1,5% maks.

- Wartość Ni obejmuje Co.

- Cu + suma nazwanych elementów, 99,4% min. Pojedyncze wartości reprezentują maksimum.

Właściwości mechaniczne C90810

| Nieruchomość | Wartość | Jednostka |

|---|

| Twardość Brinell (obciążenie 500 kg) | 95 Typowe | Bnn |

| Ocena obrabialności | 20 | – |

| Gęstość | 0.323 | LB/in³ w 68 ° F (20 ° C) |

| Wytrzymałość na rozciąganie | 40 000 | psi |

| Siła plonowania | 20 000 | psi |

| Wydłużenie | 20 | % |

| Moduł sprężystości | 15 | x 10^6 psi |

Wydajność w różnych temperaturach

| Zakres temperatur | Charakterystyka wydajności | Zalecane użycie |

|---|

| Niska temperatura (-50°C do 0°C) | Utrzymuje plastyczność i wytrzymałość | Odpowiedni |

| Temperatura pokojowa (od 20 ° C do 25 ° C) | Optymalna wytrzymałość i odporność na zużycie | Ideał |

| Podwyższona temperatura (100 ° C do 200 ° C) | Zachowuje siłę, ale może odczuwać lekkie zmiękczenie | Do przyjęcia |

| Wysoka temperatura (> 200 ° C) | Nie zalecane do przedłużającego się użytkowania | Niepolecane |

Zastosowania branżowe

| Przemysł | Aplikacje | Kluczowe korzyści |

|---|

| Maszyny Przemysłowe | Łożyska, koła zębate, wały, koła zębate | Wysoka odporność na zużycie |

| Morski | PMIPS WIRSELLERS, COALDY | Odporność na korozję |

| Budowa | Komponenty ruchome, gramofonie do mostów | Siła i trwałość |

| Automobilowy | Pierścienie tłokowe | Niski współczynnik tarcia |

| Energia | Złączki parowe | Odporność na ciepło |

| Górnictwo | Ciężkie tuleje | Odporność na uderzenie |

| Przemysł lotniczy | Tuleje do lądowania | Wysoka pojemność obciążenia |

| Ropa i Gaz | Elementy zaworu | Odporność na korozję w trudnych środowiskach |

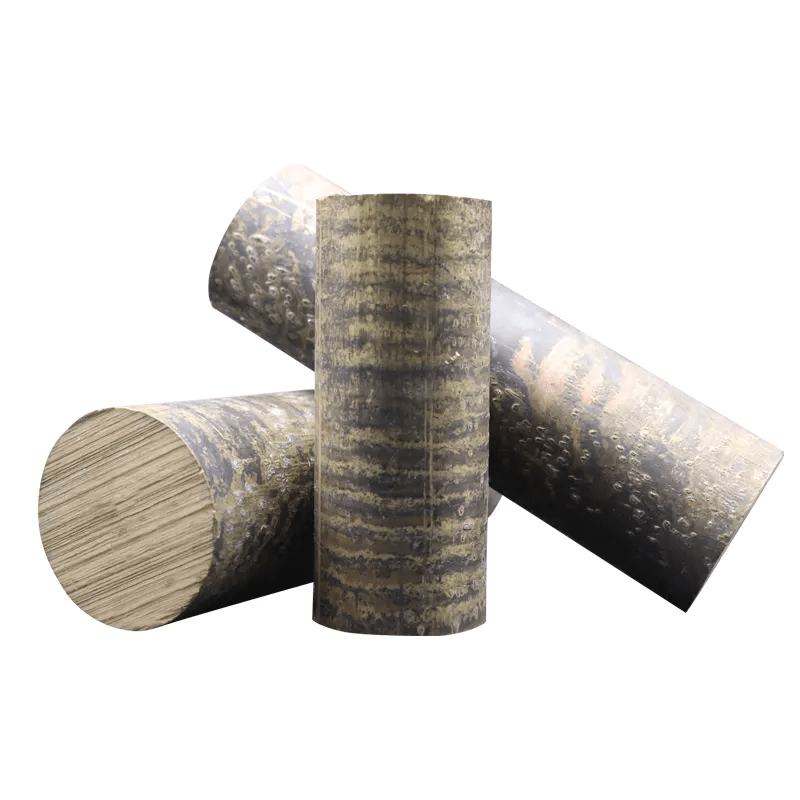

Dostępność kształtu i rozmiaru

| Kształt | Zakres rozmiarów | Długość standardowa |

|---|

| Solidki | 1 ″ do 6 ″ O.D. | 144″ |

| Rury | 1 ″ do 6 ″ O.D. | 144″ |

| Prostokąty | Do 10 ″ | 144″ |

| Talerze | Do 24 ″ grubości | 96 ″ x 240 ″ |

| Pręty | 0O średnicy .25 ″ do 12 ″ | 144″ |

| Niestandardowe kształty | Zgodnie z wymogiem | Różni się |

Dostępne formularze

| Formularz | Typowe zastosowanie | Dostępność |

|---|

| Częściowo zakończone | Dalsze przetwarzanie | Wspólny |

| Młyn | Bezpośrednie użycie | Szeroko dostępne |

| Kształty bliskie | Minimalne obróbki | Na żądanie |

| Zapas baru | Obróbka | Standard |

| Płyta | Duże płaskie komponenty | Wspólny |

| Profil lub kształt strukturalny | Określone aplikacje | Na żądanie |

| Odkuwki | Komponenty o wysokiej wytrzymałości | Ograniczony |

| Odlewy | Złożone kształty | Wspólny |

Standardy produkcyjne i zgodność

| Standard/zgodność | Region | Znaczenie |

|---|

| Federalna ustawa o bezpiecznej wodzie pitnej - SDWA | USA | Bezpieczeństwo wody |

| S. 3874 Federalna redukcja ołowiu w ustawie o wodzie pitnej | USA | Zawartość ołowiu |

| Kalifornia AB1953 | Kalifornia, USA | Zawartość ołowiu |

| Vermont Act 193 | Vermont, USA | Zawartość ołowiu |

| ASTM B505 | Międzynarodowy | Ciągłe odlewanie stopów miedzianych |

| ASTM B271 | Międzynarodowy | Odlewy odśrodkowe ze stopu miedzi |

| ISO 1338 | Międzynarodowy | Rzuć stopy miedzi |

| On H5111 | Japonia | Brązowe odlewy |

Standardy i odpowiednie oceny w różnych krajach

| Kraj | Standard | Odpowiednia klasa |

|---|

| USA | NAS | C90810 |

| Niemcy | OD | CUSN12 |

| Japonia | JIS | CAC704 |

| Zjednoczone Królestwo | BS | HTB1 |

| Francja | NF | CUSN12 |

| Włochy | UNI | CUSN12 |

| Rosja | GOST | Bro12 |

| Chiny | GB | ZCUSN12 |

| Międzynarodowy | ISO | CUSN12 |

Charakterystyka spawania

| Metoda spawania | Stosowność | Uwagi | Rozgrzej temp |

|---|

| Spawanie gazowe | Dobrze | Użyj fosforu brązowego pręta wypełniacza | 150-200 ° C. |

| Spawanie TIG | Doskonały | Użyj czystego argonowego gazu | W razie potrzeby |

| Ja spawanie | Dobrze | Użyj brązowego przewodu wypełniacza | W razie potrzeby |

| Spawanie | Sprawiedliwy | Użyj brązowych elektrod | W razie potrzeby |

| Spawanie oporowe | Słaby | Niepolecane | nie dotyczy |

| Spawanie wiązki elektronów | Dobrze | Dla precyzyjnych aplikacji | W razie potrzeby |

| Spawanie laserowe | Sprawiedliwy | Wymaga starannej kontroli | W razie potrzeby |

Charakterystyka przetwarzania

| Proces | Stosowność | Uwagi | Kluczowe rozważenie |

|---|

| Obróbka | Dobrze | Ocena maszynowości wynosząca 20 | Wybór narzędzia |

| Formowanie | Sprawiedliwy | Ograniczona formalność z powodu wysokiej zawartości cyny | Unikaj nadmiernego deformacji |

| Kucie | Słaby | Niepolecane | nie dotyczy |

| Odlew | Doskonały | Idealny do odlewania piasku i odśrodkowego | Właściwa szybkość chłodzenia |

| Wyrzucenie | Słaby | Zwykle nie wytłaczane | nie dotyczy |

| Głęboki rysunek | Słaby | Ograniczona plastyczność | Niepolecane |

| Spinning | Sprawiedliwy | Możliwe z odpowiednimi technikami | Unikaj stwardnienia pracy |

| Broaching | Dobrze | Nadaje się do precyzyjnego rozmiaru | Zużycie narzędzia |

Charakterystyka polerowania

| Metoda polerowania | Wynik | Zalecane ścierne |

|---|

| Polerowanie mechaniczne | Dobre wykończenie powierzchniowe osiągalne | Związki tlenku glinu lub diamentów |

| Polerowanie chemiczne | Umiarkowane wyniki | Zastrzeżone rozwiązania |

| Elektropolerowanie | Doskonałe do wykończenia o wysokim połysku | Elektrolity na bazie kwasu fosforowego |

| Polerowanie | Możliwe wysokie połysk | Miękkie kółki z drobnym ściernym |

| Uciekanie | Precyzyjne wykończenie | Diamentowe lub krzemowe związki węglika |

| Honing | Dobry do cylindrycznych powierzchni | Związane kamienie ścierne |

Obróbka cieplna

| Obróbka cieplna | Zakres temperatur | Zamiar | Metoda chłodzenia |

|---|

| Wyżarzanie | 550-650 ° C. | Ulga stresu i zmiękczenie | Powolne chłodzenie |

| Leczenie roztworem | Nie dotyczy | C90810 nie jest podlewa | nie dotyczy |

| Utwardzanie wiekowe | Nie dotyczy | C90810 nie jest stwardnienia wieku | nie dotyczy |

| Odprężanie | 260-370 ° C. | Zmniejsz naprężenia wewnętrzne | Chłodzenie powietrzem |

| Normalizacja | Zwykle nie wykonywane | nie dotyczy | nie dotyczy |

| hartowanie | Niepolecane | Może powodować zniekształcenie | nie dotyczy |

Charakterystyka przetwarzania zimnego

| Proces | Stosowność | Uwagi | Alternatywna sugestia |

|---|

| Praca na zimno | Ograniczony | Wysoka zawartość cyny zmniejsza plastyczność | W razie potrzeby rozważ gorącą pracę |

| Rysunek na zimno | Słaby | Niepolecane | Zamiast tego użyj obróbki |

| Walcowanie na zimno | Słaby | Niepolecane | Rozważ odlewane lub obrabiane formy |

| Zimny nagłówek | Nie nadaje się | Zbyt kruchy | Użyj obróbki lub castingu |

| Kucie na zimno | Nie nadaje się | Brak niezbędnej plastyczności | Rozważ gorące kucie lub casting |

| Śrutowanie | Sprawiedliwy | Może poprawić właściwości powierzchniowe | Używaj ostrożnie |

Zalety i wady C90810

| Zalety | Niedogodności | Rozważania |

|---|

| Wysoka wytrzymałość | Ograniczona odkształcalność | Projektowanie minimalnego formowania |

| Doskonała odporność na zużycie | Wyższy koszt w porównaniu z niektórymi brązami | Rozważ za aplikacje krytyczne |

| Dobra odporność na korozję | Nie nadaje się do zastosowań wymagających dużych prędkości | Używać w ustawieniach o niskiej do umiarkowanej prędkości |

| Niski współczynnik tarcia | Ograniczona zdolność do pracy | Projektowanie formularzy lub obrabianych form |

| Nadaje się do dużych obciążeń | Nie podlewa ciepło | Wybierz aplikacje, które nie wymagają obróbki cieplnej |

| Dobra obrabialność | Stosunkowo wysoka gęstość | Rozważ wagę w projektowaniu |

| Doskonałe właściwości łożyska | Podatne na szkodniki cynowe w bardzo niskich temperaturach | Unikaj przedłużonej ekspozycji poniżej 13 ° C |

| Dobra stabilność wymiarowa | Może być trudne do spawania | Użyj odpowiednich technik spawania |

| Odporna na korozję wody morskiej | Nie tak silny jak stal | Użyj w odpowiednich warunkach obciążenia |

| Niska przepuszczalność magnetyczna | Wyższy koszt niż mosiądz | Uzasadnić koszty wymaganiami dotyczącymi wydajności |

Podobne produkty

| Stop | Numer UNS | Główny skład | Kluczowe różnice |

|---|

| C90700 | C90700 | Cu-Sn-Zn | Niższa cyna, wyższa zawartość cynku |

| C91100 | C91100 | Z Sn | Wyższa zawartość cyny, bez ołowiu |

| C93200 | C93200 | Z SN-PB | Wyższa zawartość ołowiu w celu poprawy maszyny |

| C95400 | C95400 | Z A-up | Aluminiowy brąz z innym profilem właściwości |

| C95500 | C95500 | Cu-al-ni-fe | Brąz niklu-aluminiowy o wyższej wytrzymałości |

| C86300 | C86300 | Cu-mn-ni-fe | Brąz manganu o wyższej sile |

| C92200 | C92200 | Cu-Sn-Pb-Zn | Navy M metal z inną kompozycją |

Porównanie C90810 z podobnymi produktami

| Nieruchomość | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| Wytrzymałość na rozciąganie (psi) | 40 000 | 36 000 | 45 000 | 35 000 | 90 000 |

| Granica plastyczności (psi) | 20 000 | 18 000 | 25 000 | 18 000 | 45 000 |

| Wydłużenie (%) | 20 | 25 | 15 | 20 | 15 |

| Twardość Brinella | 95 | 70 | 100 | 65 | 190 |

| Odporność na korozję | Doskonały | Dobrze | Doskonały | Dobrze | Doskonały |

| Obrabialność | Dobrze | Bardzo dobry | Sprawiedliwy | Doskonały | Sprawiedliwy |

| Spawalność | Sprawiedliwy | Dobrze | Sprawiedliwy | Słaby | Dobrze |

| Odporność na zużycie | Doskonały | Dobrze | Doskonały | Dobrze | Doskonały |

| Koszt | Wysoki | Umiarkowany | Bardzo wysoki | Umiarkowany | Wysoki |

| Typowe zastosowania | Łożyska wytrzymałe | Ogólny kanał | Łożyska o wysokim obciążeniu | Tuleje, łożyska | Komponenty morskie |

Wniosek:

C90810 High Tin Bronze to wyspecjalizowany stop, który oferuje unikalną kombinację nieruchomości, co czyni go nieocenionym w różnych zastosowaniach przemysłowych. Jego wysoka zawartość cyny przyczynia się do doskonałej wytrzymałości, odporności na zużycie i odporności na korozję, szczególnie w warunkach o dużym obciążeniu, niskiej prędkości. Chociaż ma ograniczenia w zakresie tworzenia i zastosowań o wysokiej temperaturze, C90810 wyróżnia się w branżach takich jak inżynieria morska, maszyny przemysłowe i budownictwo.

Wszechstronność stopu jest widoczna w szerokim zakresie dostępnych form i rozmiarów, przestrzegania międzynarodowych standardów i dobrej możliwości. Jednak projektanci i inżynierowie muszą rozważyć swoje specyficzne cechy, takie jak ograniczone możliwości pracy na zimno i opcje uzdatniania ciepła, przy włączeniu C90810 do swoich projektów.

W porównaniu z podobnymi stopami C90810 wyróżnia się równowagą siły, odporności na zużycie i odporności na korozję. Jego unikalny profil nieruchomości sprawia, że jest to idealny wybór do zastosowań, w których te cechy są kluczowe, uzasadniając jego wyższe koszty w krytycznych elementach.

Podsumowując, wysoka brąz C90810 nadal jest cennym materiałem we współczesnej inżynierii, oferując niezawodną wydajność w wymagających środowiskach, w których inne stopy mogą nie być.