Wstęp

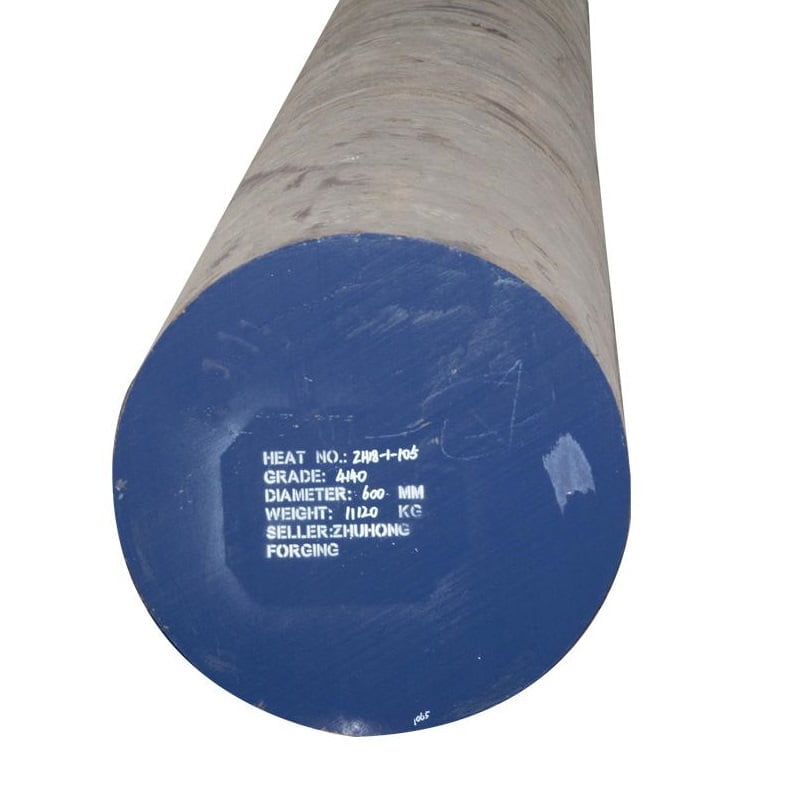

S45C i 42CrMo4 to dwa gatunki stali węglowej i stopowej szeroko stosowane w różnych zastosowaniach inżynieryjnych i produkcyjnych. Artykuł ten zawiera dokładne porównanie tych dwóch materiałów, koncentrując się na ich składzie chemicznym, właściwościach mechanicznych, reakcjach na obróbkę cieplną, zastosowaniach oraz ich odpowiednich zaletach i wadach.

Skład chemiczny

Skład chemiczny zarówno S45C, jak i 42CrMo4 ma kluczowe znaczenie przy określaniu ich właściwości mechanicznych i ogólnej wydajności.

| Element | Skład S45C (%) | Skład 42CrMo4 (%) |

|---|---|---|

| Węgiel (C) | 00,42% – 0,48% | 00,38% – 0,45% |

| Mangan (Mn) | 00,60% – 0,90% | 00,60% – 0,90% |

| Chrom (Cr) | – | 00,90% – 1,20% |

| Molibden (Mo) | – | 00,15% – 0,30% |

| Fosfor (P) | 00,03% maks | 00,03% maks |

| Siarka (S) | 00,03% maks | 00,03% maks |

Wyjaśnienie składu chemicznego

- Węgiel (C): S45C ma nieco wyższą zawartość węgla niż 42CrMo4, przyczyniając się do jego właściwości. Wyższa zawartość węgla zazwyczaj zwiększa twardość i wytrzymałość.

- Chrom (Cr) i molibden (Mo): 42CrMo4 zawiera chrom i molibden, które poprawiają twardość, odporność na korozję i wytrzymałość, dzięki czemu nadaje się do zastosowań dynamicznych i poddawanych dużym naprężeniom.

- Mangan (Mn): Obydwa gatunki mają podobną zawartość manganu, który pomaga w odtlenianiu i poprawia hartowność.

Właściwości mechaniczne

Właściwości mechaniczne odgrywają kluczową rolę w określaniu wydajności pod obciążeniem i stresem.

| Nieruchomość | S45C | 42CrMo4 |

|---|---|---|

| Granica plastyczności (MPa) | Około 355 MPa | Około 600 – 800 MPa |

| Wytrzymałość na rozciąganie (MPa) | 570 – 700 MPa | 700 – 900 MPa |

| Wydłużenie (%) | 14% (minimum) | 12% (minimum) |

| Twardość (HB) | 170 – 210 HB | 250 – 300 HB |

Szczegółowe wyjaśnienie właściwości mechanicznych

- Siła plonowania: 42CrMo4 ma znacznie wyższą granicę plastyczności niż S45C, co czyni go bardziej odpowiednim do zastosowań wymagających dużych naprężeń.

- Wytrzymałość na rozciąganie: Podobnie wytrzymałość na rozciąganie 42CrMo4 przewyższa wytrzymałość S45C, co wskazuje na lepszą nośność.

- Wydłużenie: S45C ma lepsze właściwości wydłużające, dzięki czemu może ulegać większym odkształceniom plastycznym w porównaniu do 42CrMo4.

- Twardość: 42CrMo4 jest na ogół twardszy niż S45C, co wpływa na jego odporność na zużycie i trwałość.

Reakcje na obróbkę cieplną

Proces obróbki cieplnej może wpływać na właściwości mechaniczne obu gatunków.

| Rodzaj obróbki cieplnej | S45C | 42CrMo4 |

|---|---|---|

| hartowanie | Nadaje się do hartowania | Nadaje się do hartowania |

| Ruszenie | Zmniejsza łamliwość, zachowując jednocześnie wytrzymałość | Poprawia wytrzymałość, jednocześnie zwiększając twardość |

Wyjaśnienie obróbki cieplnej

- hartowanie: Obydwa materiały można hartować w celu zwiększenia twardości, ale 42CrMo4 ma tendencję do osiągania większej twardości ze względu na zawarte w nim pierwiastki stopowe.

- Ruszenie: Odpuszczanie jest niezbędne po hartowaniu w celu złagodzenia naprężeń. Obydwa materiały korzystają z odpuszczania, przy czym 42CrMo4 zwiększa wytrzymałość przy jednoczesnym zachowaniu twardości.

Aplikacje

S45C i 42CrMo4 są wykorzystywane w różnych zastosowaniach w zależności od ich właściwości.

| Podanie | S45C | 42CrMo4 |

|---|---|---|

| Przekładnie | Powszechnie używane | Stosowany w przekładniach pracujących pod dużym obciążeniem |

| Wały | Nadaje się do ogólnego użytku | Wały o wysokiej wydajności |

| Części maszyn | Ogólne części inżynieryjne | Krytyczne komponenty wymagające dużej wytrzymałości |

| Narzędzia | Nie jest powszechnie używany | Stosowane do narzędzi skrawających i matryc |

| Komponenty samochodowe | Często używany | Powszechnie stosowany w osiach i wałach korbowych |

Wyjaśnienie zastosowań

- S45C: Dobra skrawalność i zrównoważone właściwości sprawiają, że nadaje się do ogólnych zastosowań inżynieryjnych.

- 42CrMo4: Elementy stopowe i wysoka wytrzymałość sprawiają, że nadaje się do zastosowań dynamicznych, w tym do części samochodowych, gdzie istotna jest trwałość.

Zalety i wady

Zarówno S45C, jak i 42CrMo4 mają swoje specyficzne zalety i wady.

| Aspekt | S45C | 42CrMo4 |

|---|---|---|

| Zalety | – Dobra skrawalność | – Wyższa wytrzymałość i twardość |

| – Ekonomiczne w zastosowaniach ogólnych | – Doskonała wytrzymałość i odporność na zmęczenie | |

| – Zrównoważone właściwości | – Nadaje się do środowisk o dużym stresie | |

| Niedogodności | – Niższa wytrzymałość w porównaniu do 42CrMo4 | – Wyższy koszt w porównaniu do S45C |

| – Ograniczona twardość | – Trudniejsze w obróbce |

Szczegółowe wyjaśnienie zalet i wad

- Zalety S45C: Dobra obrabialność i opłacalność sprawiają, że nadaje się do różnych zastosowań inżynieryjnych.

- Wady S45C: Niższa wytrzymałość i twardość mogą ograniczać jego skuteczność w zastosowaniach wymagających dużych naprężeń.

- Zalety 42CrMo4: Zwiększona wytrzymałość, wytrzymałość i odporność na zmęczenie sprawiają, że idealnie nadaje się do wymagających zastosowań.

- Wady 42CrMo4: Zwiększona twardość może skomplikować procesy obróbki, a jej koszt jest wyższy w porównaniu do S45C.

Wniosek

Wybór pomiędzy S45C i 42CrMo4 zależy od konkretnych wymagań aplikacji. S45C nadaje się do ogólnych zastosowań inżynieryjnych, oferując równowagę wytrzymałości i obrabialności, podczas gdy 42CrMo4 jest preferowany ze względu na wysoką wytrzymałość, wytrzymałość i przydatność w zastosowaniach dynamicznych. Zrozumienie różnic w składzie chemicznym, właściwościach mechanicznych, reakcji na obróbkę cieplną i zastosowaniach pomoże inżynierom i producentom w dokonaniu świadomego wyboru materiałów dostosowanych do potrzeb projektu.