P20 steel and 4140 steel are both popular materials in the field of industrial manufacturing and tooling, but they serve different purposes due to their distinct properties.

P20 Steel:

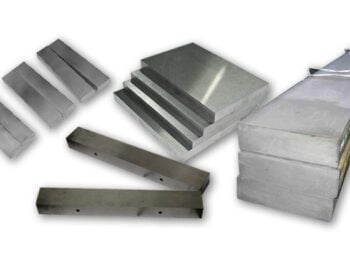

- Usage: P20 steel is primarily used for making plastic injection mold cavities and tooling. It is widely chosen for its excellent machinability and polishability, making it suitable for high-quality surface finishes required in plastic molding applications.

- Composition: P20 steel is a low-alloy tool steel that contains chromium and molybdenum as primary alloying elements. The exact composition can vary, but typically it has around 1% carbon, 1.9% chromium, and 0.2% molybdenum.

- Properties: P20 steel is known for its good toughness, machinability, and weldability. It can be hardened and tempered to achieve a good balance of hardness and toughness, which is beneficial for mold making.

4140 Steel:

- Usage: 4140 steel is commonly used in a variety of mechanical applications where high strength and toughness are required. It is often used for components such as gears, shafts, axles, bolts, and studs, where hardness and wear resistance are critical.

- Composition: 4140 steel is a chromium-molybdenum alloy steel that contains about 0.40% carbon, along with chromium (about 0.8%) and molybdenum (around 0.2%).

- Properties: 4140 steel exhibits excellent toughness, good fatigue resistance, and high torsional strength. It can be heat treated to achieve a wide range of mechanical properties, making it versatile for different applications.

Comparison:

- Application Focus: P20 steel is specialized for plastic injection molding applications due to its polishability and corrosion resistance against acidic plastics. On the other hand, 4140 steel is used in a broader range of mechanical applications requiring strength, toughness, and wear resistance.

- Material Properties: P20 steel offers good machinability, polishability, and corrosion resistance specific to molding applications. 4140 steel provides high strength, toughness, and wear resistance suitable for demanding mechanical applications.

In summary, the choice between P20 steel and 4140 steel depends on the specific requirements of your application. P20 steel is ideal for plastic mold tooling, while 4140 steel is suitable for applications requiring high strength, toughness, and wear resistance in mechanical components.