42CrMo4 and 4140 are essentially the same grade according to different international standards. Here’s the breakdown:

- 42CrMo4: This is the European (EN) designation for the same steel alloy as AISI 4140 steel. In Europe, the alloy is typically known by its EN designation “42CrMo4” or its British BS 708M40 designation.

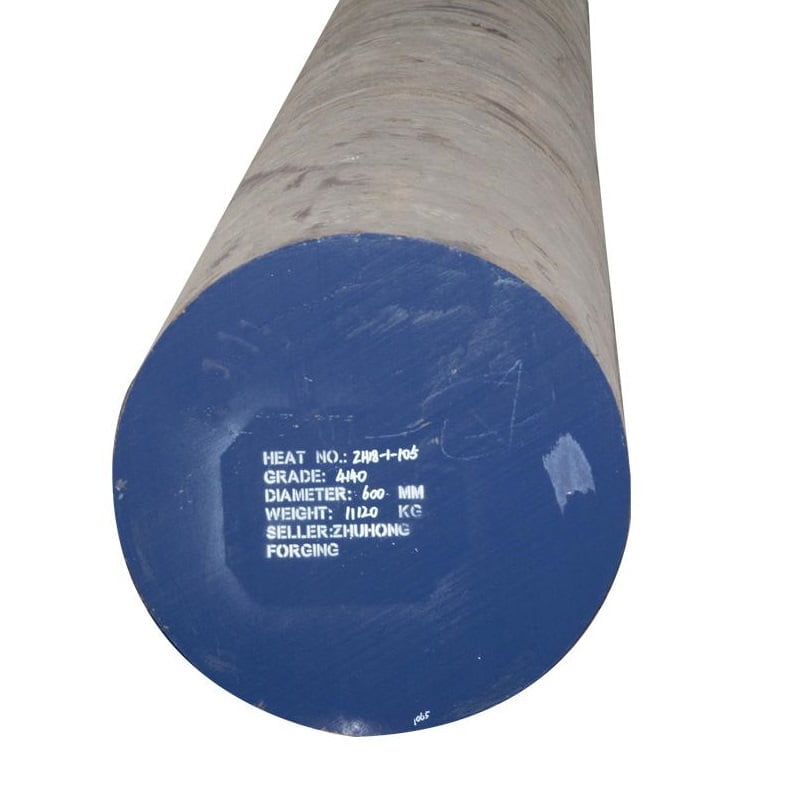

- 4140: This is the AISI (American Iron and Steel Institute) designation for a chromium-molybdenum steel (AISI 41xx series steel). Specifically, AISI 4140 is a low alloy steel containing chromium and molybdenum as strengthening agents.

Key Points:

- 화학적 구성 요소: 42CRMO4와 4140 강철은 모두 유사한 화학 조성물을 가지고 있으며, 정확한 사양 및 표준 (예 : EN 또는 AISI)에 따라 약간의 변화가 있습니다.

- 애플리케이션: 자동차, 석유 및 가스 및 기계 공학 산업과 같이 높은 강도 및 우수성이 필요한 다양한 응용 분야에 일반적으로 사용됩니다.

- 동등한 표준: 그들은 본질적으로 동일한 자료이지만 다른 조직 (EN 및 AISI)에 의해 표준화되기 때문에 다르게 지정됩니다. 제조업체와 사용자는 종종 자신의 위치와 그 표준에 따라 하나의 지정을 선택합니다.

In summary, 42CrMo4 and 4140 refer to the same steel alloy, with 42CrMo4 being the designation in the European standard and 4140 being the designation in the AISI/SAE standard. Both are widely used and interchangeable in many applications.

International Standards and Availability

While 42CrMo4 is more commonly recognized in Europe and 4140 in North America, both alloys are internationally recognized and available globally. Manufacturers and engineers can choose between these designations based on regional standards or specific project requirements, with the assurance of comparable performance and properties.

결론

In summary, 42CrMo4 and 4140 are two designations for the same alloy steel, differing only in their naming conventions based on regional standards. They share similar chemical compositions and mechanical properties, making them interchangeable in many applications across various industries. Their high strength, toughness, and versatility in heat treatment make them indispensable in manufacturing components that require durability and reliability under demanding conditions. Whether in automotive, aerospace, or construction sectors, these alloys continue to play a vital role in modern engineering, ensuring the integrity and performance of critical components worldwide.