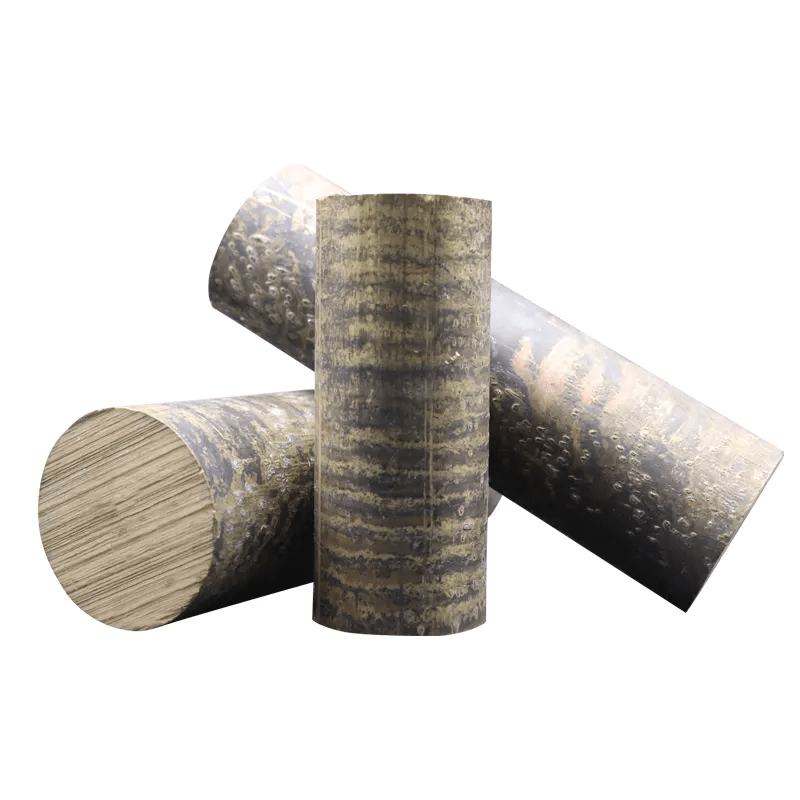

제품 소개:

C90810 고주석 청동은 탁월한 강도, 내마모성 및 내식성으로 유명한 구리 기반 합금입니다. 이 합금은 높은 하중 지지력과 저속 작동이 필요한 응용 분야에서 특히 가치가 있습니다. 높은 주석 함량은 우수한 기계적 특성에 기여하므로 다양한 산업 응용 분야에 이상적인 선택입니다.

C90810의 화학 성분

| 요소 | 백분율(%) | 기능 |

|---|

| 와 함께 | 나머지 | 비금속, 연성 및 전도성 제공 |

| Sn | 11.00-13.00 | 강도, 경도, 내마모성 향상 |

| 납 | 00.25 최대 | 가공성 향상 |

| 아연 | 0.30 최대 | 주조의 유동성 향상 |

| 철 | 0.15 최대 | 곡물 미세화제, 강도 증가 |

| NS | 0.15-0.80 | 탈산제, 유동성 향상 |

| Ni | 0.50 최대 | 강도 및 내식성 증가 |

| 알 | 0.005 최대 | 탈산제 |

| NS | 0최대 .05 | 가공성 향상 |

| SB | 0.20 최대 | 경도 증가 |

| 그리고 | 0.005 최대 | 탈산제 |

메모:

- Cu min.을 결정할 때 Cu는 Cu + Ni로 계산될 수 있습니다.

- 연속 주조의 경우 P는 최대 1.5%이어야 합니다.

- Ni 값에는 Co가 포함됩니다.

- Cu + 명명된 원소의 합, 99.4% min. 단일 값은 최대값을 나타냅니다.

C90810의 기계적 성질

| 재산 | 값 | 구상화 소둔 및 연화 처리 |

|---|

| 브리넬 경도(500Kg 하중) | 95 일반 | BHN |

| 가공성 등급 | 20 | – |

| 밀도 | 0.323 | 20°C(68°F)에서 lb/in³ |

| 인장 강도 | 40,000 | 사이 |

| 항복 강도 | 20,000 | 사이 |

| 연장 | 20 | % |

| 탄성계수 | 15 | x 10^6psi |

다양한 온도에서의 성능

| 온도 범위 | 성능 특성 | 권장 용도 |

|---|

| 저온(-50°C ~ 0°C) | 유연성과 인성을 유지합니다. | 적합한 |

| 실온(20°C~25°C) | 최적의 강도와 내마모성 | 이상적인 |

| 높은 온도(100°C ~ 200°C) | 강도는 유지되지만 약간의 부드러워짐이 발생할 수 있습니다. | 허용됨 |

| 고온(>200°C) | 장기간 사용을 권장하지 않음 | 권장하지 않음 |

산업 응용

| 산업 | 애플리케이션 | 주요 이점 |

|---|

| 산업기계 | 베어링, 기어, 샤프트, 웜기어 | 그리고 좋은 광택성 |

| 선박 | 펌프 임펠러, 밸브 본체 | 내식성 |

| 건설 | 이동식 교량 부품, 교량용 턴테이블 | 강도와 내구성 |

| 자동차 | 피스톤 링 | 낮은 마찰 계수 |

| 에너지 | 스팀 피팅 | 내열성 |

| 채광 | 견고한 부싱 | 충격 저항 |

| 항공우주 | 랜딩기어용 부싱 | 높은 부하 용량 |

| 석유 및 가스 | 밸브 부품 | 열악한 환경에서의 내식성 |

모양 및 크기 가용성

| 모양 | 크기 범위 | 표준 길이 |

|---|

| 고체 | 1″ ~ 6″ O.D. | 144″ |

| 튜브 | 1″ ~ 6″ O.D. | 144″ |

| 직사각형 | 최대 10인치 | 144″ |

| 접시 | 최대 24인치 두께 | 96인치 x 240인치 |

| 막대 | 00.25″ ~ 12″ 직경 | 144″ |

| 사용자 정의 모양 | 요구 사항에 따라 | 다양함 |

사용 가능한 양식

| 형태 | 일반적인 사용 | 유효성 |

|---|

| 반제품 | 추가 처리 | 흔한 |

| 밀 스톡 | 직접 사용 | 널리 사용 가능 |

| 니어넷 형태 | 최소한의 가공 | 요청 시 |

| 스톡 바 | 가공 | 기준 |

| 그릇 | 대형 평면 부품 | 흔한 |

| 프로필 또는 구조적 형태 | 특정 애플리케이션 | 요청 시 |

| 단조품 | 고강도 부품 | 제한된 |

| 주물 | 복잡한 모양 | 흔한 |

생산 표준 및 규정 준수

| 표준/규정 준수 | 지역 | 관련성 |

|---|

| 연방 안전 식수법 – SDWA | 미국 | 물 안전 |

| S. 3874 연방 식수 내 납 감소법 | 미국 | 납 함량 |

| 캘리포니아 AB1953 | 캘리포니아, 미국 | 납 함량 |

| 버몬트법 193 | 미국 버몬트주 | 납 함량 |

| ASTM B505 | 국제적인 | 구리 합금의 연속 주조 |

| ASTM B271 | 국제적인 | 구리 기반 합금 원심 주물 |

| ISO 1338 | 국제적인 | 주조 구리 합금 |

| HE H5111 | 일본 | 청동 주물 |

다양한 국가의 표준 및 해당 등급

| 국가 | 기준 | 해당 등급 |

|---|

| 미국 | 표준 및 화학 성분 | C90810 |

| 독일 | 에서 | CuSn12 |

| 일본 | JIS | CAC704 |

| 영국 | 학사 | HTB1 |

| 프랑스 | NF | CuSn12 |

| 이탈리아 | 유니 | CuSn12 |

| 러시아 | 고스트 | 브로12 |

| 중국 | GB | ZCuSn12 |

| 국제적인 | ISO | CuSn12 |

용접특성

| 용접방법 | 적당 | 노트 | 예열온도 |

|---|

| 가스용접 | 좋은 | 인청동 충전재 사용 | 150-200°C |

| TIG 용접 | 훌륭한 | 순수 아르곤 차폐 가스 사용 | 필요에 따라 |

| 미그 용접 | 좋은 | 청동 필러 와이어 사용 | 필요에 따라 |

| 스틱용접 | 공정한 | 청동 전극을 사용 | 필요에 따라 |

| 저항 용접 | 가난한 | 권장되지 않음 | 해당 없음 |

| 전자빔 용접 | 좋은 | 정밀 애플리케이션용 | 필요에 따라 |

| 레이저 용접 | 공정한 | 세심한 통제가 필요함 | 필요에 따라 |

가공특성

| 프로세스 | 적당 | 노트 | 주요 고려사항 |

|---|

| 가공 | 좋은 | 가공성 등급 20 | 도구 선택 |

| 형성 | 공정한 | 높은 주석 함량으로 인해 성형성이 제한됨 | 과도한 변형을 피하십시오 |

| 단조 | 가난한 | 권장되지 않음 | 해당 없음 |

| 주조 | 훌륭한 | 모래 및 원심 주조에 이상적 | 적절한 냉각 속도 |

| 압출 | 가난한 | 일반적으로 압출되지 않음 | 해당 없음 |

| 딥 드로잉 | 가난한 | 제한된 연성 | 권장되지 않음 |

| 제사 | 공정한 | 적절한 기술로 가능 | 작업 강화를 피하십시오 |

| 브로칭 | 좋은 | 정밀한 크기 조정에 적합 | 공구 마모 |

연마특성

| 연마 방법 | 결과 | 권장 연마재 |

|---|

| 기계적 연마 | 우수한 표면 조도 달성 가능 | 알루미나 또는 다이아몬드 화합물 |

| 화학적 연마 | 보통 결과 | 독점 솔루션 |

| 전해연마 | 고광택 마감에 탁월 | 인산 기반 전해질 |

| 버핑 | 고광택 가능 | 미세한 연마재가 포함된 부드러운 천 휠 |

| 랩핑 | 정밀한 마무리 | 다이아몬드 또는 탄화규소 화합물 |

| 호닝 | 원통형 표면에 적합 | 접착된 연마석 |

열처리

| 열처리 | 온도 범위 | 목적 | 냉각방식 |

|---|

| 가열 냉각 | 550-650°C | 스트레스 완화 및 완화 | 느린 냉각 |

| 용액 처리 | 해당 없음 | C90810은 열처리가 불가능합니다. | 해당 없음 |

| 노화경화 | 해당 없음 | C90810은 노화 방지되지 않습니다. | 해당 없음 |

| 스트레스 풀기 | 260-370°C | 내부 응력 감소 | 공기 냉각 |

| 정규화 | 일반적으로 수행되지 않음 | 해당 없음 | 해당 없음 |

| 담금질 | 권장되지 않음 | 왜곡이 발생할 수 있음 | 해당 없음 |

냉간 가공 특성

| 프로세스 | 적당 | 노트 | 대안 제안 |

|---|

| 냉간 가공 | 제한된 | 주석 함량이 높으면 연성이 감소합니다. | 필요한 경우 열간 가공을 고려하십시오. |

| 냉간 인발 | 가난한 | 권장되지 않음 | 대신 기계 가공을 사용하세요 |

| 냉간 압연 | 가난한 | 권장되지 않음 | 주조 또는 기계 가공 형태 고려 |

| 콜드 헤딩 | 적합하지 않음 | 너무 부서지기 쉬움 | 기계 가공 또는 주조 사용 |

| 냉간 단조 | 적합하지 않음 | 필요한 연성이 부족합니다. | 열간 단조 또는 주조를 고려하십시오. |

| 쇼트 피닝 | 공정한 | 표면 특성을 향상시킬 수 있습니다. | 주의해서 사용하세요 |

C90810의 장점과 단점

| 장점 | 단점 | 고려사항 |

|---|

| 고강도 | 제한된 성형성 | 최소한의 성형을 위한 설계 |

| 우수한 내마모성 | 일부 청동에 비해 높은 비용 | 중요한 애플리케이션에 대해 고려 |

| 좋은 내식성 | 고속 애플리케이션에는 적합하지 않음 | 저속에서 중간 속도 설정에 사용 |

| 낮은 마찰 계수 | 제한된 냉간 가공 능력 | 주조 또는 가공 형태를 위한 설계 |

| 무거운 하중에 적합 | 열처리 불가 | 열처리가 필요하지 않은 용도에 선택 |

| 우수한 가공성 | 상대적으로 높은 밀도 | 디자인에서 무게를 고려하세요 |

| 우수한 베어링 특성 | 매우 낮은 온도에서는 주석 해충에 취약함 | 13°C 이하에서 장기간 노출을 피하세요 |

| 우수한 치수 안정성 | 용접이 어려울 수 있습니다. | 적절한 용접 기술을 사용하십시오 |

| 바닷물 부식에 강함 | 강철만큼 강하지는 않아요 | 적절한 부하 조건에서 사용 |

| 낮은 투자율 | 황동보다 비용이 높음 | 성능 요구 사항에 따른 비용 정당화 |

유사한 제품

| 합금 | UNS 번호 | 주요 구성 | 주요 차이점 |

|---|

| C90700 | C90700 | Cu-Sn-Zn | 주석 함량이 낮고 아연 함량이 높음 |

| C91100 | C91100 | Sn 포함 | 주석 함량이 높고 납이 없음 |

| C93200 | C93200 | Cu-Sn-Pb | 향상된 가공성을 위한 높은 납 함량 |

| C95400 | C95400 | Cu-Al-Fe | 다양한 특성을 지닌 알루미늄 청동 |

| C95500 | C95500 | Cu-Al-Ni-Fe | 강도가 더 높은 니켈-알루미늄 청동 |

| C86300 | C86300 | Cu-Mn-Ni-Fe | 강도가 더 높은 망간청동 |

| C92200 | C92200 | Cu-Sn-Pb-Zn | 다양한 구성의 네이비 M 건메탈 |

C90810과 유사 제품 비교

| 재산 | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| 인장 강도(psi) | 40,000 | 36,000 | 45,000 | 35,000 | 90,000 |

| 항복 강도(psi) | 20,000 | 18,000 | 25,000 | 18,000 | 45,000 |

| 신장률(%) | 20 | 25 | 15 | 20 | 15 |

| 브리넬 경도 | 95 | 70 | 100 | 65 | 190 |

| 내식성 | 훌륭한 | 좋은 | 훌륭한 | 좋은 | 훌륭한 |

| 가공성 | 좋은 | 매우 좋은 | 공정한 | 훌륭한 | 공정한 |

| 용접성 | 공정한 | 좋은 | 공정한 | 가난한 | 좋은 |

| 내마모성 | 훌륭한 | 좋은 | 훌륭한 | 좋은 | 훌륭한 |

| 비용 | 높은 | 보통의 | 매우 높음 | 보통의 | 높은 |

| 일반적인 응용 분야 | 견고한 베어링 | 범용 | 고하중 베어링 | 부싱, 베어링 | 해양 부품 |

결론:

C90810 고주석 청동은 고유한 특성 조합을 제공하는 특수 합금으로 다양한 산업 응용 분야에서 매우 유용합니다. 높은 주석 함량은 특히 고하중, 저속 설정에서 우수한 강도, 내마모성 및 내식성에 기여합니다. C90810은 성형성과 고온 응용 분야에 한계가 있지만 해양 엔지니어링, 산업 기계, 건설 등의 산업에서 탁월한 성능을 발휘합니다.

합금의 다용성은 사용 가능한 다양한 형태와 크기, 국제 표준 준수, 우수한 기계 가공성에서 분명하게 드러납니다. 그러나 설계자와 엔지니어는 C90810을 프로젝트에 통합할 때 제한된 냉간 가공 능력 및 열처리 옵션과 같은 특정 특성을 고려해야 합니다.

유사한 합금과 비교하여 C90810은 강도, 내마모성 및 내식성의 균형이 돋보입니다. 고유한 특성 프로필은 이러한 특성이 중요한 응용 분야에 이상적인 선택이 되어 중요한 구성 요소의 높은 비용을 정당화합니다.

요약하자면, C90810 고주석청동은 다른 합금이 부족할 수 있는 까다로운 환경에서 안정적인 성능을 제공하면서 계속해서 현대 엔지니어링의 귀중한 소재로 자리매김하고 있습니다.