ナイモニック 75 の紹介

NIMONIC 合金はニッケルとクロムで構成されています。これらの合金は、高温での低クリープ性と高性能が特徴です。チタンやアルミニウムなどの添加剤は、合金の強度を高めるために使用されます。 NIMONIC 合金は、1940 年代にイギリスで初めて開発されました。

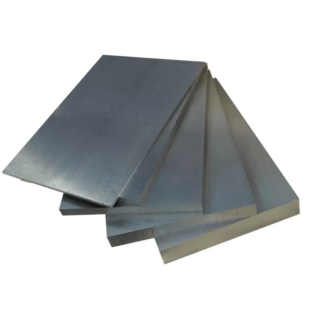

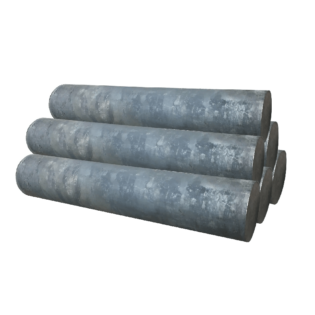

市販されているNIMONIC合金は、NIMONIC 75、NIMONIC 90、NIMONIC 100、 ナイモニック80A、 81、 NIMONIC 合金 75 は、添加剤としてチタンと炭素を含む 80/20 ニッケルクロム合金です。この合金は、1940 年代にタービンブレードとして使用するために初めて導入されました。容易に製造および溶接できます。この合金は、優れた耐食性、機械的特性、耐熱性を示します。この合金を利用できる標準形状には、押出成形品、六角平坦品、パイプ、プレート、ストリップ、ワイヤなどがあります。

このデータシートでは、NIMONIC 合金 75 の化学組成、特性、および用途について説明します。

Nimonic 75 ニッケル基超合金

Nimonic 75/NIMONIC® アロイ 75 (UNS N06075/W.Nr. 2.4951 & 2.4630) は、チタンとカーボンの添加量が制御された 80/20 ニッケルクロム合金です。プロトタイプのホイットル ジェット エンジンのタービン ブレードとして 1940 年代に初めて導入されましたが、現在では主に、高い動作温度での中程度の強度と耐酸化性および耐スケール性が求められるシート用途に使用されています。これは今でもガスタービンエンジニアリングのほか、工業用熱処理、炉部品、熱処理装置にも使用されています。容易に製造および溶接できます。

Nimonic 75/NIMONIC® アロイ 75 (UNS N06075/W.Nr. 2.4951 & 2.4630) は、 80チタンとカーボンの添加量を制御した /20 ニッケルクロム合金。プロトタイプのホイットル ジェット エンジンのタービン ブレードとして 1940 年代に初めて導入されましたが、現在では主に、高い動作温度での中程度の強度と耐酸化性および耐スケール性が求められるシート用途に使用されています。これは今でもガスタービンエンジニアリングのほか、工業用熱処理、炉部品、熱処理装置にも使用されています。容易に製造および溶接できます。

ニモニック 75 の化学組成:

| % | で | Cr | 鉄 | ん | C | そして | 博士 | の | 銅 |

|---|---|---|---|---|---|---|---|---|---|

| 分 | バランス | 18 | 0 | 0 | 0.08 | 0 | 0 | 0.2 | 0 |

| マックス | バランス | 21 | 5 | 1 | 0.15 | 1 | 0.03 | 0.6 | 0.50 |

ナイモニック 75 アプリケーション:

- 航空宇宙用板金製造

- ガスタービンエンジン部品

- 工業炉部品

- 熱処理装置および治具

- 原子力工学