モネル K-500 説明

MONEL K-500 合金は、400 と同等の耐食性を持ちながら、より高い機械的強度と硬度を備えています。優れた耐食性と長期的な構造安定性を備えています。

主に航空エンジンの作動温度が750℃以下のタービンブレードやガスタービンブレードの製造に使用されます。船舶のファスナーやスプリングの製造に使用されます。化学装置用ポンプ・バルブ部品。製紙装置のパルプブレードなど

製品仕様範囲:

鍛造品、棒品、ゼロカット、ストリップ、リング、ワイヤー、フランジなどの製品もお客様のご要望に応じて製作可能です。

特徴 | モネル K-500 (UNS N05500)MONEL K-500 合金は同等の耐食性を持っています。 400、しかしより高い機械的強度と硬度を持っています。優れた耐食性と長期的な構造安定性を備えています。主に航空エンジンの作動温度が750℃以下のタービンブレードやガスタービンブレードの製造に使用されます。船舶のファスナーやスプリングの製造に使用されます。化学装置用ポンプ・バルブ部品。製紙装置のパルプブレードなど | ||||||||

まとめ | MONEL 合金 400 の耐食性と、より優れた強度および硬度を組み合わせた、析出硬化可能なニッケル銅合金です。また、透磁率が低く、-150°F (-101°C) の低温まで非磁性です。ポンプシャフト、油井の工具や器具、ドクターブレードやスクレーパー、スプリング、バルブトリム、ファスナー、船舶用プロペラシャフトなどに使用されます。 | ||||||||

標準 | パイプ、チューブ、シート、ストリップ、板、丸棒、平棒、鍛造素材、六角、線材。 | ||||||||

製品形態 | |||||||||

ASTM に基づく化学組成 (重量%) | 分。 | 最大。 | 分。 | 最大。 | 分。 | 最大。 | |||

| で | 63 | 銅 | 27 | 33 | C | 0.18 | |||

| Cr | コ | そして | 0.5 | ||||||

| 鉄 | 2 | アル | 2.3 | 3.15 | P | ||||

| モー | の | 0.35 | 0.85 | S | 0.01 | ||||

| W | ん | 1.5 | N | ||||||

物理的な | 密度、g/cm3 | 8.44 | |||||||

定数 | 融解範囲、℃ | 1315-1350 | |||||||

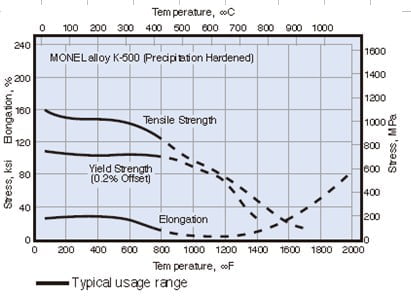

典型的な | (析出硬化) | ||||||||

機械式 | 引張強さ、ksi | 160 | |||||||

プロパティ | メガパスカル | 1100 | |||||||

| 降伏強さ (0.2% オフセット)、ksi | 115 | ||||||||

| メガパスカル | 790 | ||||||||

| 伸長、 % | 20 | ||||||||

| |||||||||

微細構造 | モネルニッケル銅の基本組成にアルミニウムとチタンを加えて製造されたモネルK-500も面心立方構造を持っています。時効硬化状態では、極微視的なガンマプライム Ni3Al 相が形成されます。 | ||||||||

キャラクター | モネル K-500 は、広範囲の自然および化学環境において優れた耐食性、塩化物イオン応力腐食割れに対する優れた耐性、および非常に高い強度と硬度を備えています。時効硬化後のモネル K-500 は、ニッケル銅合金 (モネル 400) よりも約 2 ~ 3 倍高い機械的特性、約 650 ℃ までの高い引張特性、優れた耐腐食疲労性、および -135 ℃ までの非磁性での透磁率を備えています。 | ||||||||

耐食性 | 一般に、モネル K500 の耐食性はモネル 400 と同等です。純水から鉱酸、塩、アルカリに至るまで、幅広い媒体に対して優れた耐食性を示します。 | ||||||||

| Monel K-500 は、塩化物イオンによる応力腐食割れの影響をほとんど受けません。時効状態では、合金は降伏強度に近い応力で湿った空気を含んだフッ化水素酸蒸気中で応力腐食割れを起こしやすい可能性があります。 | |||||||||

| 高速の海水や海洋大気中では良好な耐食性を示しますが、動きの遅い海水や停滞した海水では孔食が発生する場合があります。 Nicorros Al は、酸性ガス環境でも優れた耐性を示します。 | |||||||||

アプリケーション | |||||||||

| Monel K-500 は、海洋、化学、石油化学、造船業界で幅広く使用されています。 | |||||||||

| 典型的なアプリケーションには次のようなものがあります。 | |||||||||

| 1. 船舶用バルブシール、ポンプスリーブ、ウェアリング | |||||||||

| 環境 – 高い強度と海水に対する耐性; | |||||||||

| 2. ファスナー、例:海洋大気および潮汐水で使用されるボルト - 塩化物を含む環境に対する耐性。 | |||||||||

| 3. ドクターブレードとスクレーパー。 | |||||||||

| 4. 牽引ケーブルの外装 - 高強度、非磁性、耐海水性。 | |||||||||

| 5. 非磁性ドリルカラー、バルブ、計装スリーブなどの油井掘削装置 – 塩化物含有媒体および酸性ガス環境に対する耐性。 | |||||||||

| 6.スプリング – さまざまな腐食性媒体に対する耐性。 | |||||||||

| 7.航空計器部品 - 非磁性。 | |||||||||