インコネル 686 の紹介

超合金または高性能合金は、非常に高い温度や厳しい機械的ストレス下、さらには高い表面安定性が必要な場合でも機能する能力を備えています。優れた耐クリープ性と耐酸化性を備え、さまざまな形状で製造できます。

超合金の強化は固溶硬化、加工硬化、析出硬化によって行われます。超合金には、望ましい結果を達成するために、さまざまな組み合わせで多数の元素が含まれています。

Inconel 686™ は単相 Ni-Cr-Mo-W 合金で、主に腐食性の高い用途、例えば、腐食性の高い用途に使用されます。混合酸が使用される排ガス脱硫システムおよび処理プラント。この合金は局所的な孔食が困難な分野でも使用されます。

次のデータシートには、Inconel 686™ の詳細が記載されています。

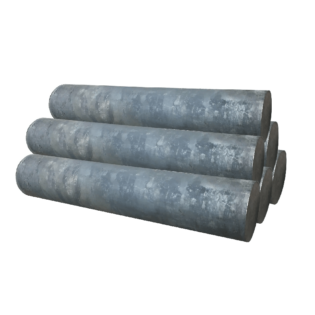

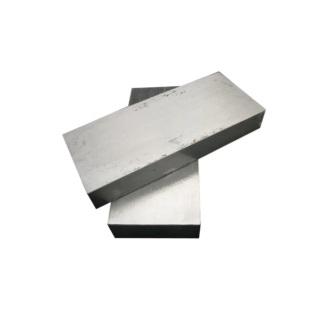

インコネル 686 合金鋼棒

INCONEL® 合金 686 (UNS N06686/W.Nr. 2.4606) は、単相のオーステナイト系 Ni-Cr-Mo-W 合金であり、さまざまな過酷な環境において優れた耐食性を発揮します。ニッケル (Ni) とモリブデン (Mo) が豊富に含まれているため、還元条件下で優れた耐性が得られ、クロム (Cr) が豊富に含まれているため、酸化媒体に対する耐性が得られます。モリブデン (Mo) とタングステン (W) は、孔食などの局所的な腐食に対する耐性を高めます。鉄(Fe)は特性を高めるために厳密に管理されています。低炭素 (C) は粒界析出を最小限に抑え、溶接継手の熱影響部の耐食性を維持します。一般腐食、孔食、隙間腐食に対する耐性は合金 (Cr+Mo+W) 含有量とともに増加し、INCONEL 合金 686 は競合材料よりも高いスコアを示します。 INCONEL 合金 686 は、米国特許 5,019,184 によって保護されています。

INCO-WELD® 溶加材および溶接電極 686 CPT® として指定される、その組成が一致した溶接製品は、硫酸または塩酸、その 2 つの混合物、および高温濃酸塩化物中での隙間腐食または孔食に対して、溶接後の優れた耐性も備えています。ソリューション。これらの溶接製品は、異なる溶接用途や競合する溶接用途にも使用されます。

Inconel® 686 は、さまざまな腐食性媒体中での一般腐食、応力腐食割れ、孔食や隙間腐食に対して優れた耐性を示します。ニッケルとモリブデンの含有量が多いため、還元条件下で優れた耐性が得られ、クロムの含有量が多いため、酸化媒体に対する耐性が得られます。タングステンの添加により、局部耐食性がさらに向上します。溶接領域の熱影響部の耐食性を維持するために、粒界析出を最小限に抑えるために炭素含有量が制限されています。

Inconel® 686 は、高濃度のハロゲン化物を含む混合酸溶液の取り扱いにも適していることが証明されており、pH レベル 1 以下および塩化物レベル 100,000 ppm を超える混合酸媒体に対して良好な耐性を示しています。

インコネル合金 686 は、化学処理、汚染管理、紙パルプ製造、および廃棄物管理用途における攻撃的な媒体に対する耐性のために使用されます。

インコネル 686 ケミカルコンプ位置:

次の表は、 インコネル 686™ の化学組成。

| 要素 | コンテンツ (%) |

|---|---|

| ニッケル、Ni | 59 |

| クロム、Cr | 19-23 |

| モリブデン、モリブデン | 15-17 |

| 鉄、鉄 | ≤ 5 |

| タングステン、西 | 3.0~4.40 |

| マンガン、ミネソタ州 | ≤ 0.75 |

| リン、P | ≤ 0.040 |

| 硫黄、S | ≤ 0.020 |

| チタン、チタン | 0.020-0.25 |

| 炭素、C | ≤ 0.010 |

インコネル 686 の物理的特性:

Inconel 686™ の物理的特性を次の表に示します。

| プロパティ | メトリック | インペリアル |

|---|---|---|

| 密度 | 8.72 g/cm3 | 00.315ポンド/インチ3 |

| 融点 | 1338~1380℃ | 2440~2520°F |

インコネル 686 の機械的特性:

Inconel 686™ の機械的特性を以下に示します。

| プロパティ | メトリック | インペリアル |

|---|---|---|

| 抗張力 | 721.9MPa | 104700 psi |

| 降伏強さ (@ひずみ 0.200%) | 364MPa | 52800 psi |

| 弾性率 | 207GPa | 30000 ksi |

| せん断弾性率 | 77GPa | 11200ksi |

| ポアソン比 | 0.34 | 0.34 |

| 破断伸び | 71% | 71% |

インコネル 686 の熱特性:

インコネル 686™ の熱特性を以下に示します。

| プロパティ | メトリック | インペリアル |

|---|---|---|

| 熱膨張係数 (@21-100°C/69.8-212°F) | 11.97μm/m℃ | 6.650 μインチ/インチ°F |