基本性能要件

どのような金型鋼板を選択する場合でも、その基礎の硬さ、強度、靭性は要件を満たしている必要があります。結局のところ、加工したい金型が異なるため、材料の要件を事前に決定する必要があります。特に、長期間の使用でも摩耗しにくく、精度に影響を与えない良好な耐摩耗性を確保します。

薄工具鋼板 注:

同時に、金型の疲労性能にも注意する必要があります。金型は加工過程で機械的衝撃や熱衝撃を受けるため、疲労性能が規定に適合していることを確認する必要があります。まず鋼の性能をテストし、サンプルを取得してその疲労を判定し、次に適切な鋼を選択します。

製品の紹介

In high speed steel, die steel, tool steel sheet is the main product, used in the manufacture of circular saw blades, paper cutter, flat cutter, cold shear cutter and other cutting tools, widely used in metal/paper/plastic/food processing industry and machinery manufacturing industry.

In the production process of LION METAL sheet, Cross rolling process is adopted to give full play to the advantage of large deformation rate. Then vacuum annealing is carried out in a protective atmosphere to avoid decarbonization and restore the superplasticity of the steel. Finally, cold rolling was carried out to obtain uniformly distributed and fine carbide, and the thickness tolerance, plate shape and surface quality of the plate were controlled in the best way.

|

High Speed Steel(Tool steel sheet)

| Brand Name | GB Type | Mat.-No. | AISI/BS type | JIS type | Typical Analysis % | Annealed/hardness | Hardness in HRC after quenching °C | ||||||||

| Data Sheet | (Ident.No.) | C | そして | ん | Cr | モー | V | W | コ | で | HB max. | HRC | |||

| M2 | 0.86-0.91 | 0.30-0.40 | 0.20-0.40 | 3.80-4.20 | 4.80-5.20 | 1.80-2.10 | 5.80-6.20 | / | / | ≤250 | 63-65 | ||||

| W6 | 0.86-0.91 | 0.3-0.4 | 0.2-0.4 | 3.8-4.0 | 4.5*4.7 | 1.70-1.90 | 5.50-6.00 | / | / | ≤250 | 63-65 | ||||

| W5 | 0.92-0.96 | 0.81-1.20 | 0.20-0.40 | 3.80-4.00 | 1.40-1.70 | 0.90-1.20 | 4.60-4.90 | / | / | ≤250 | 63-65 | ||||

| M42 | 0.91-0.95 | 0.30-0.40 | 0.20-0.40 | 3.80-4.20 | 4.80-5.20 | 1.80-2.10 | 5.80-6.20 | 1.80-2.20 | / | ≤250 | 64-66 | ||||

| DF9 | 0.92-0.96 | 0.80-1.20 | 0.20-0.40 | 3.80-4.00 | 2.70-3.20 | 1.20~1.60 | 4.60-4.90 | 1.80-2.0 | / | ≤250 | 63-64 | ||||

| W18 | 0.78-0.85 | 0.30-0.40 | 0.30-0.40 | 3.80-4.20 | / | 1.00-1.40 | 17.50 18.20 | / | / | ≤250 | 63-64 | ||||

| M35 | 0.90-0.98 | 0.30-0.40 | 0.30-0.40 | 3.80-4.20 | 4.80-5.20 | 1.80-2.10 | 5.80-6.20 | 4.50-5.20 | / | ≤250 | 64-66 | ||||

| W16 | 0.78-0.85 | 0.30-0.40 | 0.30-0.40 | 3.60-4.20 | / | 0.65-1.00 | 14.5-15.2 | / | / | ≤250 | 63-64 | ||||

| M5 | 0.80-0.85 | 0.50-0.70 | 0.30-0.40 | 3.90-4.10 | 2.30-2.70 | 1.20-1.50 | 5.40-6.00 | / | / | ≤250 | 63-64 | ||||

| W4 | 0.88-0.98 | 0.50-1.00 | 0.20-0.40 | 3.50-4.20 | 2.50-3.50 | 1.00-1.20 | 3.50-4.30 | / | / | ≤250 | 63-64 | ||||

Cold Work Steel

| Brand Name | GB Type | Mat.-No. | AISI/BS type | JIS type | Typical Analysis % | Annealed/hardness | Hardness in HRC after quenching °C | ||||||||

| Data Sheet | (Ident.No.) | C | そして | ん | Cr | モー | V | W | コ | で | HB max. | HRC | |||

| Cr12MoV | 1.45-1.70 | ≤0.40 | ≤0.40 | 11.0-12.5 | 0.40-0.60 | 0.15-0.30 | / | / | / | ≤230 | 58-60 | ||||

| D2 | 1.40-1.60 | 0.30-0.60 | 0.30-0.60 | 11.50-12.50 | 0.80-1.00 | 0.55-0.70 | / | / | / | ≤230 | 58-60 | ||||

| 1.2379 | 1.50-1.60 | 0.10-0.40 | 0.15-0.45 | 11.0-12.0 | 0.80-0.85 | 0.80-0.85 | / | / | / | ≤230 | 58-60 | ||||

| DC53 | 0.95-1.05 | 0.90-1.10 | 0.35-0.45 | 8.0-8.75 | 2.0-2.50 | 0.40-0.60 | / | / | / | ≤230 | 58-60 | ||||

| Cr8V2 | 1.10-1.20 | 0.80-1.20 | 0.30-0.50 | 8.0-9.0 | 1.40-1.60 | 1.90-2.10 | 1.40-1.60 | / | / | ≤230 | 58-60 | ||||

| 1.2360 | 0.48-0.55 | 0.80-1.05 | 0.30-0.50 | 7.60-8.40 | 1.25-1.60 | 0.35-0.50 | / | / | / | ≤230 | 58-60 | ||||

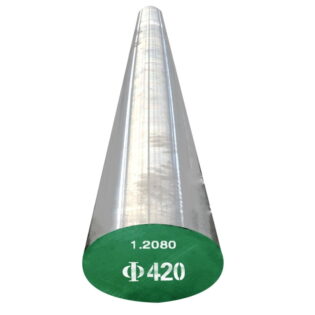

| 1.2080 | 1.90-2.20 | 0.10-0.40 | 1.15-0.45 | 11.0-12.0 | / | / | / | / | / | ≤230 | 58-60 | ||||

| L5 | 0.98-1.05 | 0.25-0.38 | 0.50-0.70 | 5.20-5.50 | 1.05-1.15 | 0.20-0.30 | ≤0.30 | / | / | ≤230 | 58-60 | ||||

| D3 | 2.00-2.20 | 0.10-0.60 | 0.20-0.60 | 11.5-13.00 | / | / | / | / | / | ≤230 | 58-60 | ||||

| D4 | 2.05-2.40 | 0.10-0.60 | 0.10-0.60 | 11.0-13.0 | 0.70-1.20 | 0.15-1.00 | / | / | / | ≤230 | 58-60 | ||||

| D2D | 1.40-1.60 | 0.30-0.60 | 0.30-0.60 | 11.50-12.50 | 0.90-1.20 | 0.80-1.00 | / | / | / | ≤230 | 58-60 | ||||

| 211 | 0.98-1.05 | 0.80-1.00 | 0.20-0.40 | 4.30-4.50 | 0.50-0.70 | 0.30-0.40 | 1.30-1.50 | / | / | ≤230 | 58-60 | ||||

|

Tool steel sheets(cross rolled, descaled, annealed in protective atmosphere, flattened, sheared or saw cut)

Tool steel sheet of other sizes or rolled to other precision may be supplied by agreement between supply and demand.

| Nomin.Thickness | 厚さの許容差 | Min. mach. allow per side | Typical dimensions | Random size | Specified size | |||

| んん | んん | んん | んん | んん | んん | んん | んん | んん |

| 幅 | 長さ | 幅 | 長さ | 幅 | 長さ | |||

| ≥ 0.60 < 1.50 | – 0 / + 0.10 | 0,15 | ≥ 500 < 800 | 1500-3000 | Execute according to supply and demand party agreement | Execute according to supply and demand party agreement | -0/+5 | -0/+10 |

| ≥ 1.50 < 2.40 | – 0 / + 0.20 | 0,15 | ≥ 600 < 1000 | 1500-3000 | ||||

| ≥ 2.50 < 4.00 | – 0 / + 0.30 | 0,15 | ≥ 600 < 1000 | 1500-3000 | ||||

| ≥ 4.00 < 7.00 | – 0 / + 0.40 | 0,15 | ≥ 600 < 1000 | 1000-2000 | ||||

| ≥ 7.00 < 10.00 | – 0 / + 0.50 | 0,15 | ≥ 500 < 800 | 1000-2000 | ||||

| ≥ 10.00-12.00 | – 0 / + 0.60 | 0,20 | ≥ 500 < 800 | 1000-2000 | ||||

Discs (laser cut, with centre hole and pin holes on request)

| 直径 | 201- < 302mm | 302- < 352mm | 352- < 452mm | ||||||

| 厚さ んん | 1.5 < 2.8 | 2.8 – < 3.3 | 3.3- <= 4.3 | 1.9 < 2.8 | 2.8- < 3.3 | 3.3- <=4.3 | 2.3- < 2.8 | 2.8 – < 3.3 | 3.3 – <=5.5 |

| 公差 | |||||||||

| Thickness tolerance/OD んん | +0.15/ -0 | +0.20/-0 | +0.20/-0 | +0.15/ -0 | +0.20/-0 | +0.20/-0 | +0.15/ -0 | +0.20/-0 | +0.20/-0 |

| Centre hole んん | +0/-0,20 | +0/-0,20 | +0/-0,20 | +0/-0,20 | +0/-0,20 | +0/-0,20 | +0/-0,20 | +0/-0,20 | +0.20/-0 |

| Pin hole んん | + / – 0,1 | + / – 0,1 | + / – 0,1 | + / – 0,1 | + / – 0,1 | + / – 0,1+ / – 0,1 | + / – 0,1 | + / – 0,1 | + / – 0,1 |

| Laser Cut Shape |

| Lasercut shapes as per drawing or DXF-file/ tolerances to be agreed(Tool steel sheet) |

| Decarburisation | ||

| Sheet thickness | High Speed Steel | Cold Work Steel |

| 0.15-3.50 | max. 3 % Thickness | max. 3 % Thickness |

| 4.00-6.00 mm | max. 3 % Thickness | max. 3 % Thickness |

| 6.00-7.00mm | max. 3 % Thickness | max. 3 % Thickness |

| 7.00-12.00mm | ≤0.30mm | ≤0.30mm |