D3 冷間工具鋼の説明

D3 鋼、アメリカン グレード、高炭素、高クロム レステナイト鋼。耐摩耗性、焼入れ性、焼き入れ性、強度と靱性、熱安定性、圧縮強度、微小変形と優れた総合性能を有し、優れた機械加工性と熱酸化耐性を有し、幅広い適応性を備えています。

冷間加工工具鋼、以下を含む D2、D3、D4、D5、D7 鋼は、高炭素、高クロム鋼です。

D3 を除くすべてのグループ D 鋼には 1% の Mo が含まれており、空気硬化されます。

D3形鋼は油焼き入れ鋼です。 ただし、一部はオーステナイト化後に真空気を使用して焼き入れできます。 その結果、D3 鋼で作られた工具は、硬化プロセス中に脆くなる傾向があります。

D2 形鋼は、グループ D で最も一般的に使用される鋼です。 D3 鋼の炭素含有量は 1.5 ~ 2.35%、クロム含有量は 12% です。

AISI D3 鋼の紹介

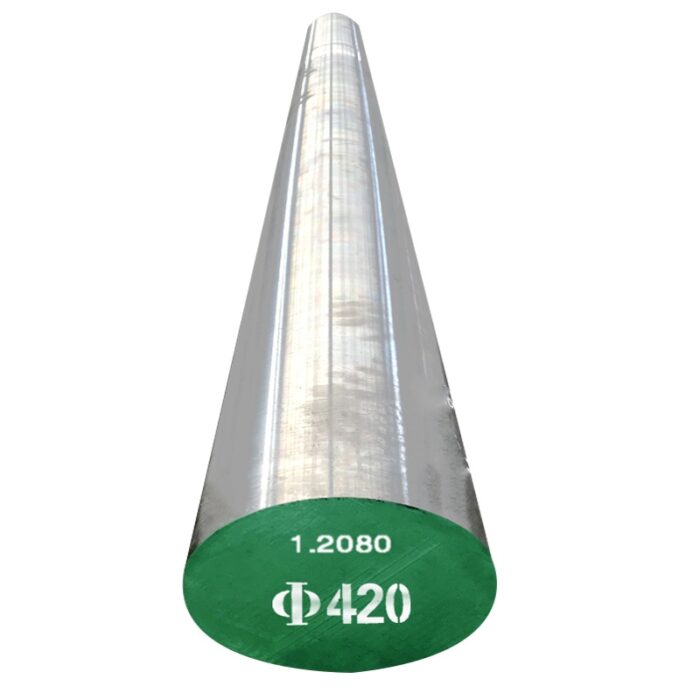

D3 冷間加工鋼は、鋼マトリックスに多量の硬質炭化物が含まれているため、摩耗摩耗や凝着摩耗に対して非常に高い耐摩耗性を備えています。靭性は中程度で、寸法安定性があり、圧縮強度が高く、二次硬化が不可能です。ISI D3 冷間加工鋼、DIN とも呼ばれます。 1.2080 (Werkstoff) および JIS SKD1 は、12% クロム合金鋼です。

D3 冷間加工鋼は、鋼マトリックスに多量の硬質炭化物が含まれているため、摩耗摩耗や凝着摩耗に対して非常に高い耐摩耗性を備えています。靭性は中程度で、寸法安定性があり、圧縮強度が高く、二次硬化が不可能です。ISI D3 冷間加工鋼、DIN とも呼ばれます。 1.2080 (Werkstoff) および JIS SKD1 は、12% クロム合金鋼です。

AISI D3 タイプの冷間工具鋼は油焼き入れされています。ただし、小さな部分はオーステナイト化後に真空を使用してガス焼き入れすることができます。その結果、タイプ D3 冷間工具鋼で作られた工具は、硬化中に脆くなる傾向があります。

AISI D3鋼相当品

| 国 | 中国 | 日本 | ドイツ | アメリカ合衆国 | イギリス |

| 標準 | GB/T 1299 | HE G4404 | DIN EN ISO4957 | ASTM A681 | BS4659 |

| 学年 | Cr12 | SKD1 | 1.2080/X210Cr12 | D3 |

AISI D3 鋼化学薬品 構成

| 学年 | C | ん | P | S | そして | Cr | V | T | モー | |||||||

| D3 | 2.00 | 2.35 | 0.10 | 0.60 | 0.03 | 0.03 | 0.10 | 0.60 | 11.00 | 13.50 | 。 。 。 | 1.10 | 。 。 。 | 1.00 | 。 。 。 | 。 。 。 |

| 1.2080/X210Cr12 | 1.90 | 2.20 | 0.20 | 0.60 | 0.10 | 0.60 | 11.00 | 13.00 | – | – | – | – | – | – | ||

| SKD1 | 1.90 | 2.20 | 0.20 | 0.60 | 0.03 | 0.03 | 0.10 | 0.60 | 11.00 | 13.00 | – | – | – | – | – | – |

AISI D3 鋼の機械的特性

機械的特性には主に、引張強さ、降伏強さ、伸び、面積または減少、硬度、衝撃値、非金属介在物などが含まれます。熱処理が異なると、機械的特性は、焼きならし、焼き戻し、QTなど異なります。物件をお知りになりたい場合は、営業マンまでお問い合わせください。

AISI D3 鋼の概要

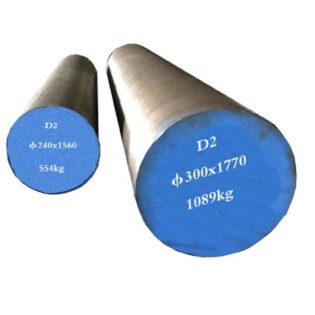

| サイズ | ラウンド | 直径6-1200mm |

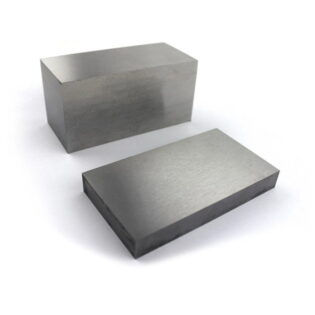

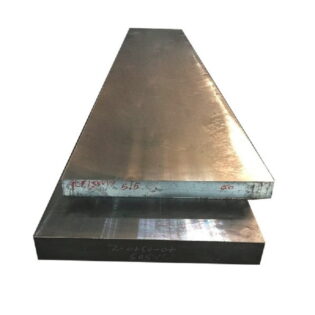

| プレート/フラット/ブロック | 厚さ 6mm~500mm | |

| 幅 20mm~1000mm | ||

| プロセス | EAF+LF+VD+鍛造+熱処理(オプション) | |

| 熱処理 | 正規化された;焼きなまし;焼き入れ済み。強化された | |

| 表面状態 | 黒;皮をむいた;研磨済み。機械加工。研削済み。向きを変えた。フライス加工 | |

| 納品状態 | 鍛造する;熱間圧延;冷間引抜 | |

| テスト | 引張強さ、降伏強さ、伸び、減少面積、衝撃値、硬度、粒度、超音波試験、米国検査、磁粉試験など | |

| 支払い条件 | T/T;L/C;/マネーグラム/ペイパル | |

| 取引条件 | FOB; CIF; C&F; etc.. | |

| パッキング | 標準パッケージ、または顧客の要求に応じて | |

| 納期 | 15~45日 | |

| 応用 | D3 は、長時間にわたる複雑なブランキングや成形ツール、硬質で研磨性の高い材料などの用途に適しています。 | |

納品状態

(1) 熱間鍛造または熱間圧延棒の場合、通常、熱間鍛造または圧延、焼鈍、荒旋削が出荷状態となります。

(2) 熱間鍛造板の場合、通常、熱間鍛造、焼鈍、表面フライス仕上げの状態で納品されます。

(3) 熱間圧延板の場合、通常、熱間圧延、焼鈍、黒色の表面が納品状態となります。

熱処理

等温アニーリング:

- 加熱して 800°その温度で 30 分から 1 時間保持できます。

- 炉を 670°C まで冷却し、その温度で少なくとも 10 時間保持します。

- 10°C/h で 630°C まで冷却します。

- 空気中で冷却します。

最大硬度:≤240 HB

ストレス解消:

- 機械加工後、最終熱処理前に実施します。

- 加熱して 600-650℃、4~6時間保持。

- 炉内で300〜350℃まで冷却。

- 空気中で冷却します。

硬化:

- 初期予熱は 350 ~ 450°C です。

- 2回目の予熱を650℃にします。750℃;

- 硬化温度 860 ~ 890°C まで加熱し、その温度で保持します。

- 高温の油(40~60℃)中で冷却。油焼き入れ硬度: 54-59HRC。

テンパリング:

焼き戻しは、必要な硬度、部品の寸法、および運転条件に応じて、550 ~ 630°C の範囲で 4 ~ 6 時間、硬化(温かい部品)から 1 時間以内に実行する必要があります。

代表的な応用例

- 主にケイ素鋼板の打ち抜き金型として使用され、耐摩耗性が高く、動荷重が小さい条件での引き伸ばしや打ち抜き金型の形状がシンプルです。

- 曲げ金型の製造に使用される高い耐摩耗性、複雑な形状のパンチ、金型、インサート、パンチ、金型の推奨事項、硬度 60 ~ 64HCR。

- 絞り耐摩耗金型の製造に使用され、推奨硬度62~64HCR。

- アルミ部品の冷間押出金型のパンチに使用する場合、推奨硬度は60~62HCRです。

- 炭素含有量0.65%~0の弾性鋼板の曲げ加工に使用します。80%、硬度60~62HRC。

- ブランキングダイ、パンチ、ローラー、ハサミ、コールドピアダイ、クレーダイに使用できます。

- 熱硬化性プラスチック成形金型に使用可能です。