1.2601 Steel Description

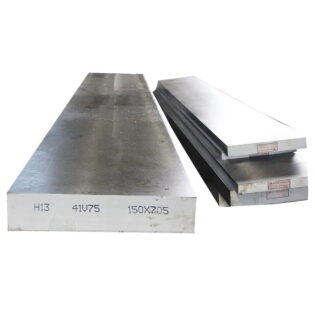

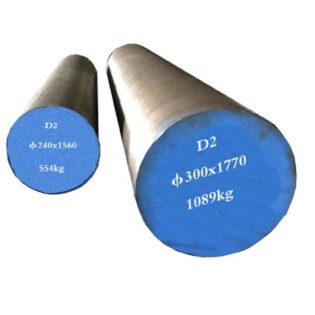

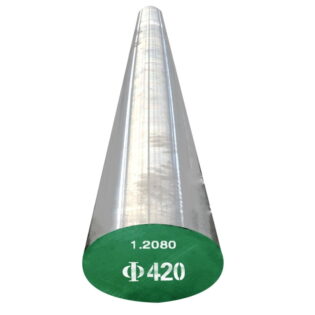

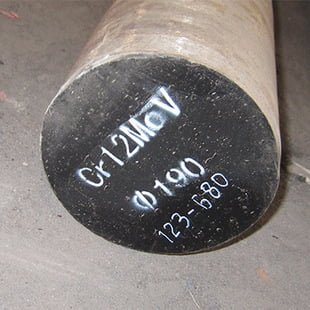

We supply in Round bar, gauge plate steel, pipe/Tube,rod, square, hexagonal, blanks, plate, sheet, precision ground flat bar, precision ground bar stock and hollow bar. provide black surface and black surface alloy steel material.

1.2601 is a German Cold work tool alloy steel material grade.it is shock resisting steel. it belong to DIN 17350 standard.

Digital Grade material number 1.2601. Metal Steel Grade W-Nr X165CrMoV12 It is a die steel, use in extrusion moulds, Hot Cast moulds. like aluminium production, Aluminium cutting mold. Our Tool Steel material 100% ultrasonic tested with good price.

Small size steel products make by hot rolled, large size steel products make by forging. 1.2601 with X165CrMoV12 is equivalent Belong to W-Nr and DIN.

Mechanical properties of Alloy Steel X165CrMoV12 | 1.2601

Hardness: Annealing 225 HB max, Q+T: 58-63 HRc, different hardness according different Tempering temperature.

- Yield strength:

Heat treatment of X165CrMoV12 | 1.2601 Cold work tool steel

- Annealing: Annealing temperature/°C: 800~830; After the annealing, degree of hardness ≤HBS: 255

- Quenching: Hardening temperature/°C: 980~1010, Quenching in oil or air

- Tempering: Commonly used drawing temperature/°C: 180~250; After tempering hardness HRC | 100°C: 63; After tempering hardness HRC | 200°C: 61; After tempering hardness HRC | 300°C: 60 ; After tempering hardness HRC | 400°C: 58

- Normalizing: at Normalizing temperature, then cool in furnace

1.2601 Cold Work Tool Steel Details

DIN 1.2601 is a Cold work tool alloy steel material grade.it is shock resisting steel. Digital Grade material number 1.2601 use in extrusion moulds, Hot Cast moulds. like aluminium production, Aluminium cutting mold. Our Tool Steel material 100 % ultrasonic tested with good price. Small size steel products make by hot rolled, large size steel products make by forging. 1.2601 with is equivalent Belong to DIN.

同等

| 国 | 中国 | 日本 | ドイツ | アメリカ合衆国 | イギリス |

| 標準 | GB/T 1299 | HE G4404 | DIN EN ISO4957 | ASTM A681 | BS4659 |

| 学年 | Cr12MoV | SKD11 | 1.2601 | D5 |

化学組成

| 学年 | C | ん | P | S | そして | W | V | Cr | ||||||

| DIN 1.2601 | 1.55 | 1.75 | 0.20 | 0.40 | 0.03 | 0.03 | 0.25 | 0.40 | 0.40 | 0.6. | 0.1 | 0.50 | 11.0 | 12.0 |

機械的性質

| 学年 | 抗張力 | 降伏強さ | 伸長 | Reduction | Impact Value | 硬度 |

| DIN 1.2601 | 488 (≥)MPa | 12% | 31% | 31J | Annealing 225 HB max, Q+T: 58-63 HRc |

Overviews

| サイズ | ラウンド | 直径6-1200mm |

| プレート/フラット/ブロック | 厚さ 6mm~500mm | |

| 幅 20mm~1000mm | ||

| プロセス | EAF+LF+VD+鍛造+熱処理(オプション) | |

| 熱処理 | 正規化された;焼きなまし;焼き入れ済み。強化された | |

| 表面状態 | 黒;皮をむいた;研磨済み。機械加工。研削済み。向きを変えた。フライス加工 | |

| 納品状態 | 鍛造する;熱間圧延;冷間引抜 | |

| テスト | 引張強さ、降伏強さ、伸び、減少面積、衝撃値、硬度、粒度、超音波試験、米国検査、磁粉試験など | |

| 支払い条件 | T/T;L/C;/マネーグラム/ペイパル | |

| 取引条件 | FOB; CIF; C&F; etc.. | |

| パッキング | 標準パッケージ、または顧客の要求に応じて | |

| 納期 | 30~45日 | |

| 応用 | DIN 1.2601 is suitable for applications High alloyed CrMoV steel for cutting tool and cold work tool steel. | |

熱処理

アニーリング:

Temperature/°C: 800~830; After the annealing, degree of hardness ≤HBS: 255

Quenching:

Hardening temperature/°C: 980~1010, Quenching in oil or air

テンパリング:

Commonly used drawing temperature/°C: 180~250;

(1) After tempering hardness HRC | 100°C : 63;

(2) After tempering hardness HRC | 200°C : 61; After tempering hardness HRC | 300°C : 60 ;

(3) After tempering hardness HRC | 400°C : 58

正規化

At Normalizing temperature, then cool in furnace

納品状態

(1) 熱間鍛造または熱間圧延棒の場合、通常、熱間鍛造または圧延、焼鈍、荒旋削が出荷状態となります。

(2) 熱間鍛造板の場合、通常、熱間鍛造、焼鈍、表面フライス仕上げの状態で納品されます。

(3) 熱間圧延板の場合、通常、熱間圧延、焼鈍、黒色の表面が納品状態となります。