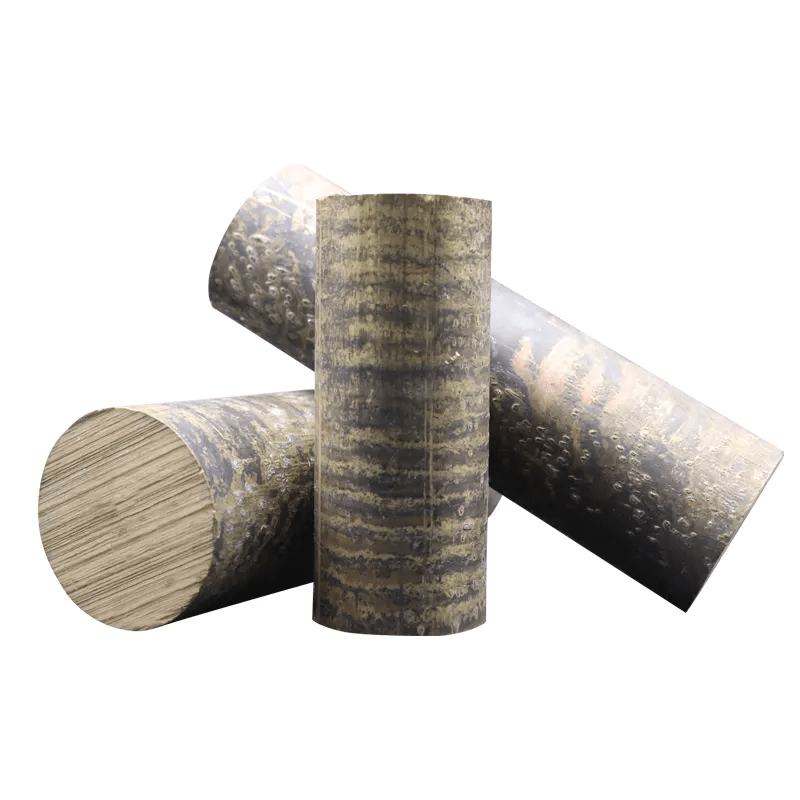

製品紹介:

C90810 High Tin Bronzeは、その例外的な強度、耐摩耗性、耐食性で知られる銅ベースの合金です。この合金は、高負荷を含む容量と低速操作を必要とするアプリケーションで特に評価されています。高いスズ含有量は、その優れた機械的特性に貢献しており、さまざまな産業用アプリケーションに理想的な選択肢となっています。

C90810の化学組成

| 要素 | パーセンテージ (%) | 関数 |

|---|

| 銅 | 残り | ベースメタルは、延性と導電率を提供します |

| SN | 11.00-13.00 | 強度、硬さ、耐摩耗性を改善します |

| 鉛 | 0最大.25 | 加工性を向上させます |

| 亜鉛 | 0最大.30 | 鋳造の流動性を改善します |

| 鉄 | 0最大.15 | 穀物の精製器は、強度を高めます |

| P | 0.15-0.80 | デオキシジ剤は、流動性を改善します |

| で | 0最大.50 | 強度と耐食性を増加させます |

| アル | 0最大.005 | デオキシジ剤 |

| S | 0最大.05 | 加工性が向上します |

| SB | 0最大.20 | 硬度を高めます |

| そして | 0最大.005 | デオキシジ剤 |

ノート:

- 決定するcu min。では、計算とcu + niでカックします。

- 連続鋳物の場合、pは最大1.5%でなければなりません。

- Ni値にはCoが含まれます。

- 指名された要素のCu +合計、99.4%min。単一の値は最大値を表します。

C90810の機械的特性

| 財産 | 価値 | ユニット |

|---|

| ブリネルの硬度(500 kg荷重) | 95典型 | BNN |

| 被削性評価 | 20 | – |

| 密度 | 0.323 | 68°F(20°C)のlb/in³ |

| 抗張力 | 40,000 | psi |

| 降伏強さ | 20,000 | psi |

| 伸長 | 20 | % |

| 弾性率 | 15 | x 10^6 psi |

さまざまな温度でのパフォーマンス

| 温度範囲 | 性能特性 | 推奨使用 |

|---|

| 低温(-50°C〜0°C) | 延性と靭性を維持します | 適切な |

| 室温(20℃~25℃) | 最適な強度と耐摩耗性 | 理想的 |

| 上昇した温度(100°Cから200°C) | 強度を保持しますが、わずかな軟化が発生する場合があります | 許容できる |

| 高温(> 200°C) | 長時間使用することはお勧めしません | 推奨されません |

産業用途

| 業界 | アプリケーション | 主な利点 |

|---|

| 産業機械 | ベアリング、ギア、シャフト、ワームギア | 高い耐摩耗性 |

| マリン | ポンプインピーラー、バルブボディ | 耐食性 |

| 工事 | 可動橋コンポーネント、橋用のターンテーブル | 強さと耐久性 |

| 自動車 | ピストンリング | 低摩擦係数 |

| エネルギー | 蒸気継手 | 耐熱性 |

| マイニング | 頑丈なブッシング | 耐衝撃性 |

| 航空宇宙 | 着陸装置用のブッシング | 高負荷容量 |

| オイルとガス | バルブコンポーネント | 過酷な環境での耐食性 |

形状とサイズの入手可能性

| 形 | サイズ範囲 | 標準長さ |

|---|

| 固体 | 1インチから6インチO.D. | 144インチ |

| チューブ | 1インチから6インチO.D. | 144インチ |

| 長方形 | 最大10インチ | 144インチ |

| プレート | 最大24インチの厚さ | 96インチx 240インチ |

| ロッド | 0.25インチから直径12インチ | 144インチ |

| カスタムシェイプ | 要件に従って | 変化します |

利用可能なフォーム

| 形状 | 典型的な使用 | 可用性 |

|---|

| 半フィニッシュ | さらなる処理 | 一般 |

| ミルストック | 直接使用 | 広く利用可能です |

| ネットの形状 | 最小限の機械加工 | リクエストに応じて |

| バーストック | 機械加工 | 標準 |

| 皿 | 大きなフラットコンポーネント | 一般 |

| プロファイルまたは構造形状 | 特定のアプリケーション | リクエストに応じて |

| 鍛造品 | 高強度部品 | 限定 |

| キャスティング | 複雑な形 | 一般 |

生産基準とコンプライアンス

| 標準/コンプライアンス | 地域 | 関連性 |

|---|

| 連邦安全な飲料水法 - SDWA | アメリカ合衆国 | 水安全 |

| S. 3874 飲料水における鉛の連邦削減法 | アメリカ合衆国 | リードコンテンツ |

| カリフォルニア AB1953 | 米国カリフォルニア | リードコンテンツ |

| バーモント州法 193 | 米国バーモント | リードコンテンツ |

| ASTM B505 | 国際的 | 銅合金の連続鋳造 |

| ASTM B271 | 国際的 | 銅塩基合金遠心鋳造 |

| ISO 1338 | 国際的 | 銅合金を鋳造します |

| HE H5111 | 日本 | ブロンズキャスティング |

各国の規格と対応グレード

| 国 | 標準 | 対応グレード |

|---|

| アメリカ合衆国 | 私たち | C90810 |

| ドイツ | から | CUSN12 |

| 日本 | 彼 | CAC704 |

| イギリス | BS | HTB1 |

| フランス | nf | CUSN12 |

| イタリア | ユニ | CUSN12 |

| ロシア | ゴスト | Bro12 |

| 中国 | GB | ZCUSN12 |

| 国際的 | ISO | CUSN12 |

溶接特性

| 溶接方法 | 適合性 | 注意事項 | 予熱温度 |

|---|

| ガス溶接 | 良い | 蛍光ブロンズフィラーロッドを使用してください | 150-200°C |

| ティグ溶接 | 素晴らしい | 純粋なアルゴンシールドガスを使用します | 必要に応じて |

| 私の溶接 | 良い | ブロンズフィラーワイヤーを使用します | 必要に応じて |

| スティック溶接 | 公平 | ブロンズ電極を使用します | 必要に応じて |

| 抵抗溶接 | 貧しい | 推奨されません | 該当なし |

| 電子ビーム溶接 | 良い | 精密アプリケーション用 | 必要に応じて |

| レーザー溶接 | 公平 | 慎重な制御が必要です | 必要に応じて |

処理特性

| プロセス | 適合性 | 注意事項 | 重要な考慮事項 |

|---|

| 機械加工 | 良い | マシン性評価20 | ツール選択 |

| 形にする | 公平 | 錫含有量が高いため、形成性が限られています | 過度の変形を避けてください |

| 鍛造 | 貧しい | 推奨されません | 該当なし |

| 鋳造 | 素晴らしい | 砂や遠心鋳造に最適です | 適切な冷却速度 |

| 押し出し | 貧しい | 通常は押し出されていません | 該当なし |

| 深い絵 | 貧しい | 限られた延性 | 推奨されません |

| 紡糸 | 公平 | 適切なテクニックで可能です | 作業硬化を避けてください |

| ブローチ | 良い | 精密サイジングに適しています | ツールウェア |

研磨特性

| 研磨方法 | 結果 | 推奨される研磨剤 |

|---|

| 機械研磨 | 良い表面仕上げが達成可能です | アルミナまたはダイヤモンド化合物 |

| 化学研磨 | 中程度の結果 | 独自のソリューション |

| 電解研磨 | 高い光沢仕上げに最適です | リン酸ベースの電解質 |

| バフ掛け | 高い輝きが可能です | 細かい研磨剤を備えた柔らかい布のホイール |

| ラッピング | 精密仕上げ | ダイヤモンドまたはシリコン炭化物化合物 |

| ホーニング | 円筒形の表面に適しています | 結合した研磨石 |

熱処理

| 熱処理 | 温度範囲 | 目的 | 冷却方法 |

|---|

| アニーリング | 550-650°C | ストレス緩和と柔らかい | ゆっくりと冷却 |

| 溶体化処理 | 適用できない | C90810は熱処理できません | 該当なし |

| 年齢硬化 | 適用できない | C90810は年齢硬化できません | 該当なし |

| 応力緩和 | 260-370°C | 内部応力を軽減する | 空冷 |

| 正規化 | 通常は実行されません | 該当なし | 該当なし |

| 焼入れ | 推奨されません | 歪みを引き起こす可能性があります | 該当なし |

コールド処理特性

| プロセス | 適合性 | 注意事項 | 代替の提案 |

|---|

| 冷間加工 | 限定 | スズ含有量が多いと延性が低下します | 必要に応じて、ホットワークを検討してください |

| 冷間引抜 | 貧しい | 推奨されません | 代わりに機械加工を使用してください |

| 冷間圧延 | 貧しい | 推奨されません | キャストまたは機械加工されたフォームを検討してください |

| コールドヘッド | 不適切 | 脆すぎます | 機械加工または鋳造を使用します |

| 冷間鍛造 | 不適切 | 必要な延性が欠けています | 熱い鍛造またはキャストを検討してください |

| ピーニングを撃った | 公平 | 表面特性を改善できます | 注意して使用してください |

C90810の利点と短所

| 利点 | 短所 | 考慮事項 |

|---|

| 高強度 | 限られた形成性 | 最小限の形成のための設計 |

| 優れた耐摩耗性 | 一部のブロンズと比較してより高いコスト | 重要なアプリケーションを検討してください |

| 良好な腐食抵抗 | 高速アプリケーションには適していません | 低速度から中程度の速度設定で使用します |

| 低摩擦係数 | 限られた冷たい作業能力 | As-Castまたは機械加工フォームの設計 |

| 重い負荷に適しています | 熱処理できない | 熱処理を必要としないアプリケーションを選択します |

| 良好な機械加工性 | 比較的高い密度 | デザインの重量を考慮してください |

| 優れたベアリング特性 | 非常に低い温度でティン害虫の影響を受けやすい | 13°C未満の長期暴露を避けてください |

| 良好な寸法安定性 | 溶接が難しい場合があります | 適切な溶接技術を使用します |

| 海水腐食に耐性があります | スチールほど強くありません | 適切な負荷条件で使用します |

| 低磁性透過性 | 真鍮よりも高いコスト | パフォーマンス要件でコストを正当化します |

類似製品

| 合金 | UNS番号 | メイン構成 | 主な違い |

|---|

| C90700 | C90700 | Cu-Sn-Zn | より低いスズ、より高い亜鉛含有量 |

| C91100 | C91100 | SNで | より高いブリキの含有量、リードなし |

| C93200 | C93200 | SN-PBで | 改善された機械加工のためのより高いリードコンテンツ |

| C95400 | C95400 | 銅-アルミニウム-鉄 | 異なるプロパティプロファイルのアルミニウムブロンズ |

| C95500 | C95500 | Cu-Al-Ni-Fe | 強度が高いニッケルアルミニウムブロンズ |

| C86300 | C86300 | cu-mn-ni-fe | 強度が高いマンガン青銅 |

| C92200 | C92200 | Cu-Sn-PB-Zn | 異なる組成のネイビーMガンメタル |

C90810と同様の製品との比較

| 財産 | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| 引張強度(psi) | 40,000 | 36,000 | 45,000 | 35,000 | 90,000 |

| 降伏強度(psi) | 20,000 | 18,000 | 25,000 | 18,000 | 45,000 |

| 伸長 (%) | 20 | 25 | 15 | 20 | 15 |

| ブリネル硬度 | 95 | 70 | 100 | 65 | 190 |

| 耐食性 | 素晴らしい | 良い | 素晴らしい | 良い | 素晴らしい |

| 被削性 | 良い | とても良い | 公平 | 素晴らしい | 公平 |

| 溶接性 | 公平 | 良い | 公平 | 貧しい | 良い |

| 耐摩耗性 | 素晴らしい | 良い | 素晴らしい | 良い | 素晴らしい |

| 料金 | 高い | 適度 | 非常に高い | 適度 | 高い |

| 代表的なアプリケーション | 頑丈なベアリング | 汎用 | ハイロードベアリング | ブッシュ、ベアリング | 海洋成分 |

結論:

C90810 High Tin Bronzeは、特性のユニークな組み合わせを提供する特殊な合金であり、さまざまな産業用途で非常に貴重なものにします。その高いスズ含有量は、特に重荷の低速設定で、優れた強度、耐摩耗性、耐食性に寄与します。フォーミン性と高温用途には制限がありますが、C90810は海洋工学、産業機械、建設などの産業に優れています。

合金の汎用性は、利用可能な幅広い形態とサイズ、国際基準の順守、および優れた機械性で明らかです。ただし、設計者とエンジニアは、C90810をプロジェクトに組み込む際に、限られたコールド作業能力や熱処理オプションなどの特定の特性を考慮する必要があります。

同様の合金と比較して、C90810は強度、耐摩耗性、耐食性のバランスで際立っています。そのユニークなプロパティプロファイルは、これらの特性が重要であるアプリケーションに理想的な選択となり、重要なコンポーネントのコストが高いことを正当化します。

要約すると、C90810 High Tin Bronzeは引き続き現代のエンジニアリングの貴重な素材であり、他の合金が不足する可能性のある環境で信頼できるパフォーマンスを提供します。