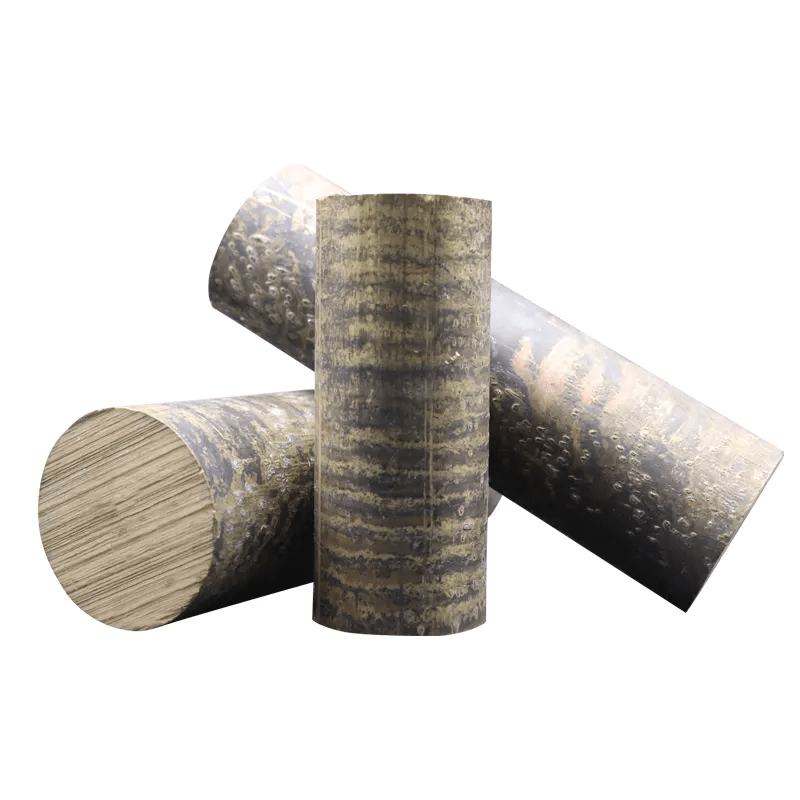

Introduzione al prodotto:

C90810 High Tin Bronze è una lega a base di rame nota per la sua eccezionale robustezza, resistenza all'usura e resistenza alla corrosione. Questa lega è particolarmente apprezzata in applicazioni che richiedono elevata capacità di carico e operazioni a bassa velocità. L'alto contenuto di stagno contribuisce alle sue proprietà meccaniche superiori, rendendolo la scelta ideale per varie applicazioni industriali.

Composizione chimica di C90810

| Elemento | Percentuale (%) | Funzione |

|---|

| Insieme a | Resto | Base Metal, fornisce duttilità e conducibilità |

| Sn | 11.00-13.00 | Migliora la robustezza, la durezza e la resistenza all'usura |

| Pb | 00,25 massimo | Migliora la lavorabilità |

| Zn | 0.30 massimo | Migliora la fluidità nel lancio |

| Fe | 0.15 massimo | Refiner di grano, aumenta la forza |

| P | 0.15-0.80 | Deossidizzatore, migliora la fluidità |

| Ni | 0.50 massimo | Aumenta la robustezza e la resistenza alla corrosione |

| Al | 00,005 massimo | Desossidizzatore |

| S | 00,05 max | Migliora la lavorabilità |

| Sb | 0.20 massimo | Aumenta la durezza |

| e | 00,005 massimo | Desossidizzatore |

Appunti:

- Nel determinare Cu min., Cuck con un calcolo e Cu + Ni.

- Per le colate continue, P sarà pari all'1,5% max.

- Il valore NI include Co.

- Cu + somma degli elementi nominati, 99,4% min. I singoli valori rappresentano i massimi.

Proprietà meccaniche di C90810

| Proprietà | Valore | Unità |

|---|

| Durezza Brinell (carico 500 Kg) | 95 tipico | BHN |

| Valutazione di lavorabilità | 20 | – |

| Densità | 0.323 | lb/in³ a 20 °C (68 °F) |

| Resistenza alla trazione | 40.000 | psi |

| Resa | 20.000 | psi |

| Allungamento | 20 | % |

| Modulo di elasticità | 15 | x 10^6 PSI |

Prestazioni a diverse temperature

| Intervallo di temperatura | Caratteristiche di performance | Uso consigliato |

|---|

| Bassa temperatura (-50 ° C a 0 ° C) | Mantiene duttilità e tenacità | Adatto |

| Temperatura ambiente (da 20°C a 25°C) | Robustezza e resistenza all'usura ottimali | Ideale |

| Temperatura elevata (da 100°C a 200°C) | Mantiene la forza ma potrebbe subire un leggero ammorbidimento | Accettabile |

| Alta temperatura (>200°C) | Non raccomandato per un uso prolungato | Non consigliato |

Applicazioni industriali

| Industria | Applicazioni | Vantaggi principali |

|---|

| Macchinari industriali | Cuscinetti, ingranaggi, alberi, ingranaggi a vite senza fine | Elevata resistenza all'usura |

| Marino | Giranti della pompa, corpi delle valvole | ma ci sono alcune limitazioni |

| Costruzione | Componenti del ponte mobili, giradischi per ponti | Forza e durata |

| Rendimento della resistenza alla trazione | Fasce elastiche | Coefficiente di attrito basso |

| Energia | Raccordi vapore | Resistenza al calore |

| Estrazione mineraria | Boccole per carichi pesanti | Resistenza all'ambiente |

| Aerospaziale | Boccole per carrello di atterraggio | Elevata capacità di carico |

| Olio e gas | Componenti della valvola | Resistenza alla corrosione in ambienti difficili |

Disponibilità di forme e dimensioni

| Forma | Gamma di dimensioni | Lunghezza standard |

|---|

| Solidi | Da 1" a 6" D.E. | 144″ |

| Tubi | Da 1" a 6" D.E. | 144″ |

| Rettangoli | Fino a 10″ | 144″ |

| Piatti | Fino a 24″ di spessore | 96″x240″ |

| Canne | 0Diametro da .25″ a 12″ | 144″ |

| Forme personalizzate | Come da requisito | Varia |

Moduli disponibili

| Modulo | Uso tipico | Disponibilità |

|---|

| Semilavorato | Ulteriore elaborazione | Comune |

| Magazzino del mulino | Uso diretto | Ampiamente disponibile |

| Forme vicine alla rete | Lavorazione minima | Su richiesta |

| Magazzino da barra | lavorazione | Standard |

| Piatto | Componenti piatti di grandi dimensioni | Comune |

| Profilo o forma strutturale | Applicazioni specifiche | Su richiesta |

| forgiati | Componenti ad alta resistenza | Limitato |

| Getti | Forme complesse | Comune |

Standard di produzione e conformità

| Standard/Conformità | Regione | Rilevanza |

|---|

| Legge federale sull’acqua potabile sicura – SDWA | Stati Uniti d'America | Sicurezza dell'acqua |

| S. 3874 Legge federale sulla riduzione del piombo nell'acqua potabile | Stati Uniti d'America | Contenuto principale |

| CaliforniaAB1953 | California, Stati Uniti | Contenuto principale |

| Legge 193 del Vermont | Vermont, Stati Uniti | Contenuto principale |

| ASTM B505 | Internazionale | Colata continua di leghe di rame |

| ASTM B271 | Internazionale | Colate centrifughe in leghe a base di rame |

| ISO 1338 | Internazionale | Leghe di rame fuse |

| HE H5111 | Giappone | Fusioni in bronzo |

Standard e gradi corrispondenti in diversi paesi

| Nazione | Standard | Grado corrispondente |

|---|

| Stati Uniti d'America | noi | C90810 |

| Germania | A PARTIRE DAL | Cusn12 |

| Giappone | JIS | Cac704 |

| Regno Unito | BS | HTB1 |

| Francia | NF | Cusn12 |

| Italia | UNI | Cusn12 |

| Russia | GOST | BrO12 |

| Cina | GB | Zcusn12 |

| Internazionale | ISO | Cusn12 |

Caratteristiche di saldatura

| Metodo di saldatura | adeguatezza | è un acciaio strutturale ad alta resistenza a bassa lega standard cinese GB | Temp. di preriscaldamento |

|---|

| Saldatura a gas | Bene | Utilizzare una bacchetta di apporto in bronzo fosforoso | 150-200°C |

| Saldatura TIG | Eccellente | Utilizzare gas di protezione argon puro | Secondo necessità |

| Me di saldatura | Bene | Utilizzare filo d'apporto in bronzo | Secondo necessità |

| Saldatura a bastone | Equo | Utilizzare elettrodi di bronzo | Secondo necessità |

| Saldatura a resistenza | Povero | Non consigliato | N / A |

| Saldatura a fascio di elettroni | Bene | Per applicazioni di precisione | Secondo necessità |

| Saldatura laser | Equo | Richiede un attento controllo | Secondo necessità |

Caratteristiche di elaborazione

| Processi | adeguatezza | è un acciaio strutturale ad alta resistenza a bassa lega standard cinese GB | Considerazione chiave |

|---|

| lavorazione | Bene | Indice di lavorabilità pari a 20 | Selezione dello strumento |

| formando | Equo | Formabilità limitata dovuta all'alto contenuto di stagno | Evitare deformazioni eccessive |

| forgiatura | Povero | Non consigliato | N / A |

| Colata | Eccellente | Ideale per colata in sabbia e centrifuga | Velocità di raffreddamento adeguata |

| Estrusione | Povero | Tipicamente non estruso | N / A |

| Disegno profondo | Povero | Duttilità limitata | Non consigliato |

| Filatura | Equo | Possibile con tecniche adeguate | Evitare l'incrudimento del lavoro |

| Brocciatura | Bene | Adatto per dimensionamenti di precisione | Usura degli utensili |

Caratteristiche di lucidatura

| Metodo di lucidatura | Risultato | Abrasivi consigliati |

|---|

| Lucidatura meccanica | È possibile ottenere una buona finitura superficiale | Composti di allumina o diamante |

| Lucidatura chimica | Risultati moderati | Soluzioni proprietarie |

| Elettrolucidatura | Eccellente per finiture ad alta lucentezza | Elettroliti a base di acido fosforico |

| Lucidatura | Elevata brillantezza possibile | Ruote in tela morbida con abrasivo fine |

| Lappatura | Finitura di precisione | Composti di diamante o carburo di silicio |

| Affilatura | Buono per superfici cilindriche | Pietre abrasive legate |

Trattamento termico

| Trattamento termico | Intervallo di temperatura | Scopo | Metodo di raffreddamento |

|---|

| Ricottura | 550-650°C | Sollievo dallo stress e addolcimento | Raffreddamento lento |

| Trattamento della soluzione | Non applicabile | C90810 non è trattabile termicamente | N / A |

| Indurimento dell'età | Non applicabile | C90810 non è induribile con l'età | N / A |

| Alleviare lo stress | 260-370°C | Ridurre le tensioni interne | Aria condizionata |

| Normalizzare | Tipicamente non eseguito | N / A | N / A |

| tempra | Non consigliato | Può causare distorsioni | N / A |

Caratteristiche della lavorazione a freddo

| Processi | adeguatezza | è un acciaio strutturale ad alta resistenza a bassa lega standard cinese GB | Suggerimento alternativo |

|---|

| Lavoro a freddo | Limitato | L'alto contenuto di stagno riduce la duttilità | Considerare il funzionamento a caldo, se necessario |

| Trafilatura a freddo | Povero | Non consigliato | Utilizzare invece la lavorazione |

| Laminazione a freddo | Povero | Non consigliato | Considera forme fuse o lavorate |

| Testa fredda | Non adatto | Troppo fragile | Utilizzare la lavorazione o la fusione |

| Forgiatura a freddo | Non adatto | Manca della duttilità necessaria | Prendi in considerazione la forgiatura a caldo o la fusione |

| Scatto | Equo | Può migliorare le proprietà della superficie | Usare con cautela |

Vantaggi e svantaggi di C90810

| Vantaggi | Svantaggi | Considerazioni |

|---|

| Molta forza | Formabilità limitata | Design per una formatura minima |

| Eccellente resistenza all'usura | Costo più elevato rispetto ad alcuni bronzi | Considerare le applicazioni critiche |

| Buona resistenza alla corrosione | Non è adatto per applicazioni ad alta velocità | Utilizzare con impostazioni di velocità da basse a moderate |

| Coefficiente di attrito basso | Capacità limitata di lavorare a freddo | Design per forme grezze o lavorate |

| Adatto per carichi pesanti | Non trattabile termicamente | Selezionare per applicazioni che non richiedono trattamento termico |

| Buona lavorabilità | Densità relativamente alta | Considera il peso nel design |

| Eccellenti proprietà portanti | Sensibile ai parassiti dello stagno a temperature molto basse | Evitare l'esposizione prolungata al di sotto di 13°C |

| Buona stabilità dimensionale | Può essere difficile da saldare | Utilizzare tecniche di saldatura adeguate |

| Resistente alla corrosione dell'acqua di mare | Non forte come l'acciaio | Utilizzare in condizioni di carico adeguate |

| Bassa permeabilità magnetica | Costo maggiore rispetto all'ottone | Giustificare i costi con i requisiti prestazionali |

Prodotti simili

| Lega | Numero UNS | Composizione principale | Differenze chiave |

|---|

| C90700 | C90700 | Cu-Sn-Zn | Meno stagno, più alto contenuto di zinco |

| C91100 | C91100 | Con-Sn | Maggiore contenuto di stagno, senza piombo |

| C93200 | C93200 | Cu-Sn-Pb | Contenuto di piombo più elevato per una migliore lavorabilità |

| C95400 | C95400 | Cu-Al-Fe | Bronzo di alluminio con profilo di proprietà diverso |

| C95500 | C95500 | Cu-Al-Ni-Fe | Bronzo al nichel-alluminio con maggiore resistenza |

| C86300 | C86300 | Cu-MN-NI-FE | Bronzo al manganese con maggiore resistenza |

| C92200 | C92200 | Cu-Sn-Pb-Zn | Navy M canna di fucile con diversa composizione |

Confronto di C90810 con prodotti simili

| Proprietà | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| Resistenza alla trazione (psi) | 40.000 | 36.000 | 45.000 | 35.000 | 90.000 |

| Resistenza allo snervamento (psi) | 20.000 | 18.000 | 25.000 | 18.000 | 45.000 |

| Allungamento (%) | 20 | 25 | 15 | 20 | 15 |

| Durezza Brinell | 95 | 70 | 100 | 65 | 190 |

| Resistenza alla corrosione | Eccellente | Bene | Eccellente | Bene | Eccellente |

| lavorabilità | Bene | Molto bene | Equo | Eccellente | Equo |

| Forgiatura a caldo | Equo | Bene | Equo | Povero | Bene |

| Resistenza all'usura | Eccellente | Bene | Eccellente | Bene | Eccellente |

| Costo | Alto | Moderare | Molto alto | Moderare | Alto |

| Applicazioni tipiche | Cuscinetti pesanti | Uso generale | Cuscinetti ad alto carico | Boccole, cuscinetti | Componenti marini |

Conclusione:

C90810 High Tin Bronze è una lega specializzata che offre una combinazione unica di proprietà, che la rendono preziosa in varie applicazioni industriali. Il suo elevato contenuto di stagno contribuisce a garantire un'eccellente robustezza, resistenza all'usura e alla corrosione, in particolare in ambienti con carichi pesanti e a bassa velocità. Sebbene presenti limitazioni nella formabilità e nelle applicazioni ad alta temperatura, C90810 eccelle in settori quali l'ingegneria navale, i macchinari industriali e l'edilizia.

La versatilità della lega è evidente nella sua ampia gamma di forme e dimensioni disponibili, nel rispetto degli standard internazionali e nella buona lavorabilità. Tuttavia, progettisti e ingegneri devono considerare le sue caratteristiche specifiche, come la limitata capacità di lavorazione a freddo e le opzioni di trattamento termico, quando incorporano C90810 nei loro progetti.

Rispetto a leghe simili, C90810 si distingue per il suo equilibrio tra resistenza, resistenza all'usura e resistenza alla corrosione. Il suo profilo di proprietà unico lo rende la scelta ideale per applicazioni in cui queste caratteristiche sono cruciali, giustificando il suo costo più elevato in componenti critici.

In sintesi, il bronzo ad alto contenuto di stagno C90810 continua a essere un materiale prezioso nell'ingegneria moderna, offrendo prestazioni affidabili in ambienti difficili dove altre leghe potrebbero non essere all'altezza.