SKD61 and SKD6 are both types of hot work tool steels, but they differ in their compositions and properties, which make them suitable for different applications.

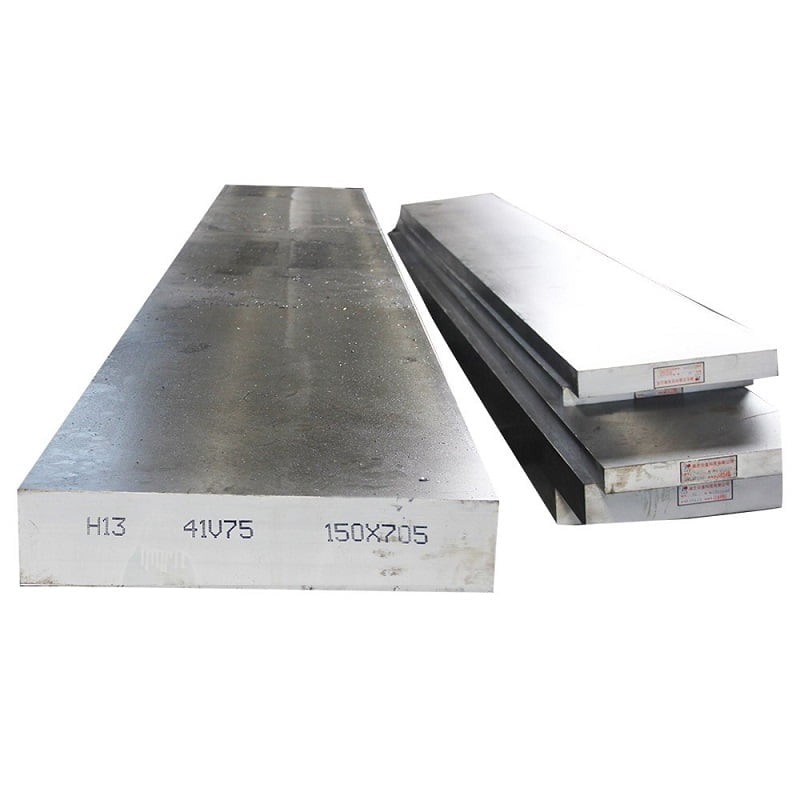

- Composition: SKD61 is a Japanese JIS standard hot work tool steel, which is equivalent to H13 tool steel in ASTM and AISI standards. Its composition typically includes:

- Carbon (C): 0.32-0.45%

- Chromium (Cr): 4.75-5.50%

- Molybdenum (Mo): 1.10-1.75%

- Vanadium (V): 0.80-1.20%

- Silicon (Si): 0.80-1.20%

- Propriétés: SKD61/H13 is known for its excellent combination of high toughness and heat resistance. It has good machinability, wear resistance, and can be hardened to around 50-52 HRC. It is widely used for making aluminum and zinc die casting dies, as well as for forging and extrusion dies.

SKD6 (H11):

- Composition: SKD6 is another hot work tool steel specified by JIS standards, equivalent to H11 tool steel in ASTM and AISI standards. Its composition typically includes:

- Carbon (C): 0.32-0.42%

- Chromium (Cr): 4.50-5.50%

- Molybdenum (Mo): 1.00-1.50%

- Vanadium (V): 0.30-0.60%

- Silicon (Si): 0.80-1.20%

- Propriétés: SKD6/H11 is characterized by its excellent resistance to thermal fatigue cracking, which makes it suitable for applications involving high temperatures and cyclic heating and cooling. It offers good toughness, high hardness after heat treatment (around 45-50 HRC), and is often used for hot punches, die casting dies, and forging dies.

Key Differences:

- Composition: SKD61 (H13) has a higher chromium content compared to SKD6 (H11), which contributes to its superior heat resistance and toughness.

- Applications: SKD61 (H13) is preferred for applications requiring higher heat resistance and toughness, such as die casting dies and extrusion molds. SKD6 (H11) is chosen for its excellent thermal fatigue resistance, making it suitable for hot forging and similar applications.

- Hardness: SKD61 (H13) typically achieves higher hardness after heat treatment compared to SKD6 (H11).

In summary, while both SKD61 (H13) and SKD6 (H11) are hot work tool steels, their differences in composition and resulting properties make them suitable for different types of hot work applications where specific properties such as heat resistance, toughness, and thermal fatigue resistance are required.