Introduction aux manchons à bride en alliage de cuivre

Les manchons à bride en alliage de cuivre sont des composants spécialisés largement utilisés dans diverses industries en raison de leurs propriétés exceptionnelles, notamment la solidité, la résistance à la corrosion et l'excellente conductivité thermique et électrique. Ces manchons constituent des éléments essentiels dans les applications mécaniques et structurelles, en particulier dans les contextes où l'intégrité et la performance fiables des joints sont primordiales.

Comprendre les alliages de cuivre

Les alliages de cuivre, principalement fabriqués à partir de cuivre combiné à d'autres métaux tels que l'étain, l'aluminium, le nickel ou le zinc, présentent des propriétés améliorées par rapport au cuivre pur. Ces améliorations peuvent inclure une résistance mécanique améliorée, une meilleure résistance à l’usure et une résistance accrue à la corrosion, ce qui les rend idéales pour les environnements exigeants. Les alliages de cuivre les plus couramment utilisés pour les manchons à bride sont le laiton (alliage cuivre-zinc), le bronze (alliage cuivre-étain) et le bronze d'aluminium (alliage cuivre-aluminium).

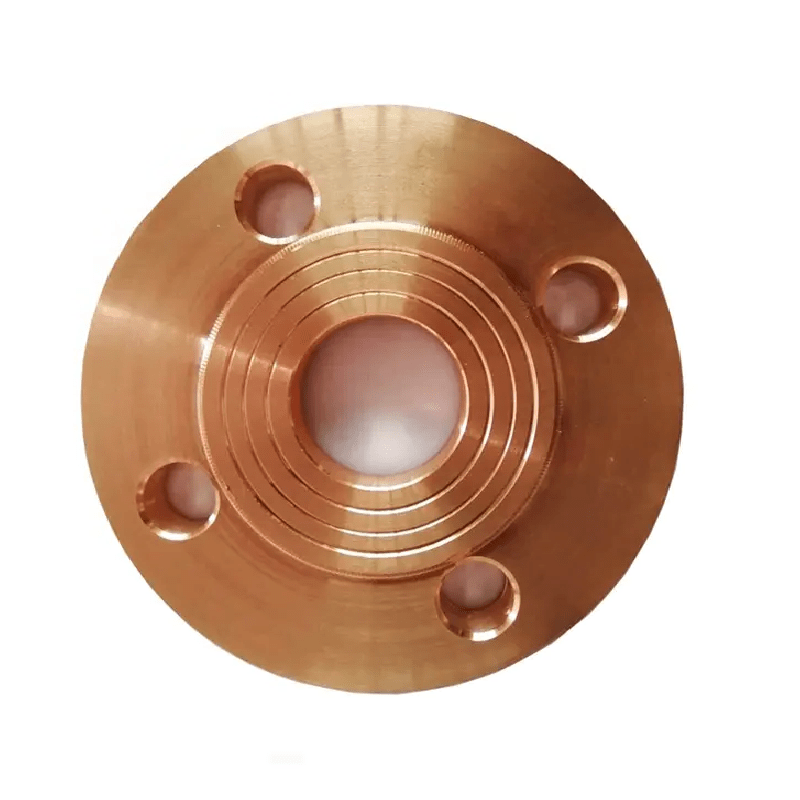

Le rôle des manchons à bride

Les manchons à bride sont des composants cylindriques conçus pour s'adapter sur un tuyau ou un arbre et sont souvent utilisés conjointement avec des raccords à bride. Ils fournissent un joint sûr et stable, supportant la dilatation thermique, les vibrations et autres contraintes mécaniques. En utilisant des matériaux en alliage de cuivre, ces manchons bénéficient d'avantages supplémentaires qui améliorent les performances de l'ensemble global.

- Résistance à la corrosion: Alliages de cuivre, notamment aluminium bronze, sont réputés pour leur résistance à la corrosion en milieu marin et industriel. Cette caractéristique prolonge considérablement la durée de vie du manchon et des composants connectés.

- Résistance mécanique: Les manchons à bride en alliage de cuivre conservent des propriétés mécaniques robustes sous différentes températures et charges. Cette solidité est essentielle pour les applications dans les systèmes à haute pression, tels que les oléoducs et les gazoducs, où la fiabilité est essentielle.

- Conductivité thermique et électrique: Les alliages de cuivre offrent une excellente conductivité thermique et électrique, ce qui les rend adaptés aux applications dans les systèmes électriques et les échangeurs de chaleur.

- Facilité d'usinage: De nombreux alliages de cuivre sont plus faciles à usiner que d’autres matériaux, ce qui permet une fabrication et une personnalisation précises pour répondre à des exigences de conception spécifiques.

Applications des manchons à bride en alliage de cuivre

Les manchons à bride en alliage de cuivre sont utilisés dans un large éventail d'industries, notamment :

- Pétrole et Gaz: Dans le secteur pétrolier et gazier, les manchons à bride sont essentiels pour maintenir l'intégrité des systèmes de tuyauterie, en particulier dans les applications offshore où la résistance à la corrosion par l'eau de mer est vitale.

- Génie maritime: Ces manchons sont couramment utilisés dans la construction navale et les applications marines, où leur résistance à la corrosion et leur solidité sont indispensables pour les composants exposés à des environnements d'eau de mer difficiles.

- La production d'énergie: Dans les centrales électriques, en particulier celles utilisant des échangeurs de chaleur et des systèmes de refroidissement, les manchons à bride en alliage de cuivre contribuent à une gestion thermique efficace et à la durabilité.

- Systèmes CVC: Dans les systèmes de chauffage, de ventilation et de climatisation, les manchons à bride contribuent à garantir des connexions fiables entre les conduits et la tuyauterie, maintenant ainsi l'efficacité et l'intégrité du système.

Considérations de fabrication

Le processus de fabrication des manchons à bride en alliage de cuivre implique généralement le moulage, le forgeage ou l'usinage. Le choix de la méthode dépend des propriétés, des dimensions et du volume de production souhaités :

- Fonderie: Souvent utilisée pour des formes complexes, la coulée permet une production de masse efficace de manchons aux designs complexes.

- Forgeage: Cette méthode améliore les propriétés mécaniques de l'alliage par déformation, le rendant ainsi adapté aux applications à haute résistance.

- Usinage: L'usinage de précision permet la production de manchons personnalisés selon des spécifications exactes, souvent requises dans des applications spécialisées.

Entretien et durée de vie

Les manchons à bride en alliage de cuivre nécessitent généralement un entretien minimal en raison de leurs propriétés résistantes à la corrosion. Des inspections régulières doivent être effectuées pour vérifier l'usure et tout signe de corrosion, en particulier dans les environnements où les manchons sont exposés à des produits chimiques ou à des températures extrêmes. Avec des soins appropriés, ces manchons peuvent fournir un service fiable pendant de nombreuses années, garantissant ainsi les performances à long terme des systèmes connectés.

Conclusion

Les manchons à bride en alliage de cuivre sont des composants indispensables dans une myriade d'applications industrielles. Leurs propriétés mécaniques et de résistance à la corrosion supérieures, combinées à une excellente conductivité thermique et électrique, en font un choix privilégié dans les environnements où les performances et la fiabilité sont essentielles. À mesure que les industries continuent d'évoluer, la demande de composants en alliage de cuivre de haute qualité, y compris les manchons à bride, restera forte, stimulant l'innovation et le développement des pratiques en matière de science des matériaux et d'ingénierie. Grâce aux progrès continus, le rôle des manchons à bride en alliage de cuivre va s'étendre, renforçant ainsi leur importance dans les solutions modernes de fabrication et d'ingénierie.