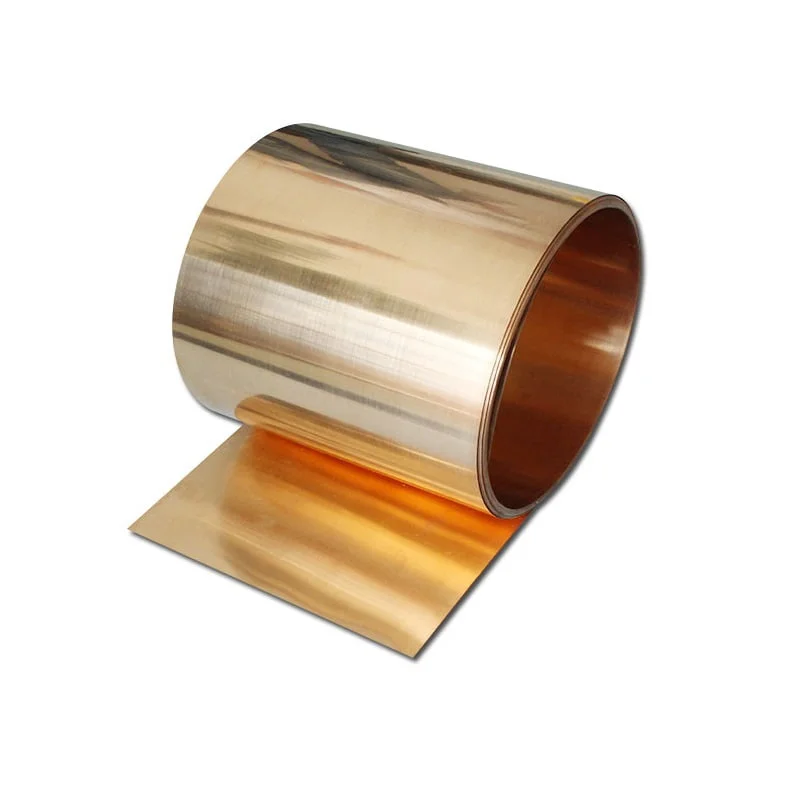

Beryllium Copper C17200: A Comprehensive Overview

Beryllium Copper C17200 is a versatile alloy known for its unique combination of properties, making it suitable for various demanding applications across industries. This article provides an in-depth look into its composition, mechanical and physical properties, applications, and considerations for use.

Composition

Beryllium Copper C17200 consists primarily of copper (Cu) alloyed with a small percentage of beryllium (Be). The typical composition is as follows:

| Copper (Cu) | 98.1% |

| Beryllium (Be) | 1.9% |

Key Properties

- Mechanical Properties: Property Value Tensile Strength 1250 MPa (181 ksi) Yield Strength (0.2% offset) 1100 MPa (160 ksi) Elongation 8% Hardness (Rockwell C) 34-45 HRc

- Physical Properties:

- Density: 8.36 g/cm³

- Melting Point: Approximately 985°C (1805°F)

- Electrical Conductivity: Approximately 22% IACS (International Annealed Copper Standard)

- Corrosion Resistance: Good corrosion resistance in various environments.

- Fatigue Resistance: Excellent fatigue resistance, suitable for cyclic loading applications.

- Machinability: Requires tools designed for machining hard materials due to its hardness.

- Weldability: Fair weldability; may require preheating and post-weld heat treatment.

Heat Treatment

Beryllium Copper C17200 is typically solution heat treated and aged to achieve the desired mechanical properties. The heat treatment process enhances its strength and hardness, crucial for applications requiring high performance under stress.

Applications

Beryllium Copper C17200 finds application in a wide range of industries, including:

- Electronics: Electrical connectors, switches, and springs due to its high electrical conductivity and spring properties.

- Manufacturing: Injection mold components, bearings, and bushings for their wear resistance and strength.

- Aerospace: Components requiring high strength-to-weight ratio, fatigue resistance, and reliability under extreme conditions.

- Oil and Gas: Non-sparking tools and equipment used in hazardous environments.

Considerations

- Safety: Beryllium is a hazardous material if handled improperly. Proper safety precautions must be followed during machining, handling, and disposal.

- Environmental Impact: Recycling and disposal should be conducted in compliance with regulations due to the presence of beryllium.

Standards

- Conforms to ASTM B196/B196M – Standard Specification for Copper-Beryllium Alloy Rod and Bar.

- Designated as UNS C17200.

Conclusion

Beryllium Copper C17200 is a high-performance alloy valued for its unique combination of strength, conductivity, and corrosion resistance. Its versatility makes it indispensable in critical applications across industries, from electronics to aerospace. Understanding its properties and applications is essential for maximizing its benefits while ensuring safety and compliance with industry standards.

For detailed specifications and further information, refer to the manufacturer’s technical datasheet and consult with industry experts.

This article aims to provide a comprehensive understanding of Beryllium Copper C17200, highlighting its attributes through organized tables for clarity and ease of reference. If you have any specific questions or need further details, feel free to ask!