WNM360 Description

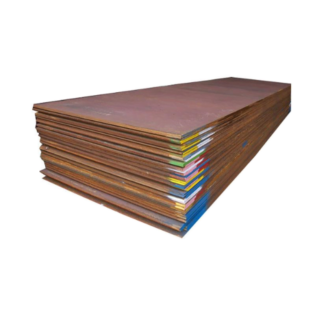

This standard applies to the quenched and tempered wear-resistant steel plate series with the steel plate thickness not greater than 100mm, and is mainly used for structural steel plates used in the processing and manufacturing of wear-resistant and vulnerable parts for mines and various construction machinery.

China Grade: WNM360

Enterprise Standard: WYJ030-2010

Application: Thickness ≤100mm quenching and tempering wear-resistant steel plate

Composition: manufacturer, purpose, hardness and quality grade

WNM360(NM360) grade is a high-grade quenched and tempered wear-resistant steel plate produced by WuSteel; its grade is low than WNM400 و نم400.

This standard applies to the quenched and tempered wear-resistant steel plate series with the steel plate thickness not greater than 100mm, and is mainly used for structural steel plates used in the processing and manufacturing of wear-resistant and vulnerable parts for mines and various construction machinery.

China Grade: WNM360

Enterprise Standard: WYJ030-2010

Application: Thickness ≤100mm quenching and tempering wear-resistant steel plate

Composition: manufacturer, purpose, hardness and quality grade

WNM360A, WNM360B, WNM360L, etc.

سمك 12-300 مم × عرض 200-2300 مم | ج | و | Mn | ص | س | مو | سجل تجاري | ني | ب |

أ | ≤0.22 | .60.60 | .61.60 | .00.025 | .0.015 | .50.50 | ≤1.00 | / | .00.004 |

ب | ≤0.22 | .60.60 | .61.60 | .00.025 | .0.015 | .50.50 | ≤1.00 | .60.60 | .00.004 |

سمك 12-300 مم × عرض 200-2300 مم | صلابة (هبو) | 20 درجة CAKV طولية J |

أ | 320~400 | supply |

ب | 320~400 | ≥21 |

رقم سري | عناصر الاختبار | عدد العينات | طريقة أخذ العينات | Experiment method |

1 | تمتد | 1 | GB/T2975-82 | GB228/T-2002 |

2 | صدمة | 3 | GB/T2975-82 | GB/T229-1994 |

3 | اختبار الانحناء | 1 | GB/T2975-82 | جيجابايت/T232 |

4 | درجة حرارة التقسية | 1 | GB/T2975-82 | GB231-84 |