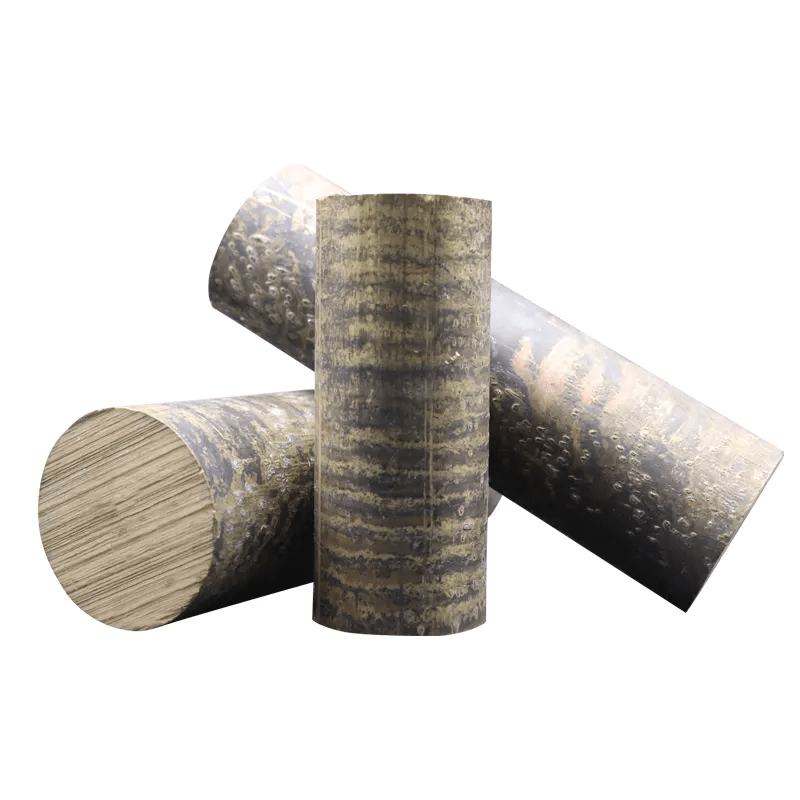

مقدمة المنتج:

C90810 High Tin Bronze عبارة عن سبيكة نحاسية معروفة بقوتها الاستثنائية ومقاومتها للتآكل ومقاومة التآكل. تحظى هذه السبيكة بتقدير خاص في التطبيقات التي تتطلب قدرة تحمل عالية وعمليات منخفضة السرعة. يساهم المحتوى العالي من القصدير في خواصه الميكانيكية الفائقة، مما يجعله خيارًا مثاليًا لمختلف التطبيقات الصناعية.

التركيب الكيميائي لـ C90810

| عنصر | نسبة مئوية (٪) | دور |

|---|

| مع | بقية | المعدن الأساسي ، يوفر ليونة وموصلية |

| Sn | 11.00-13.00 | يحسن القوة والصلابة ومقاومة التآكل |

| الرصاص | 0.25 كحد أقصى | يعزز القدرة على الماكينات |

| Zn | 0.30 كحد أقصى | يحسن السيولة في الصب |

| Fe | 0.15 كحد أقصى | مصفاة الحبوب ، يزيد من القوة |

| ص | 0.15-0.80 | Deoxidizer ، يحسن السيولة |

| ني | 0.50 كحد أقصى | يزيد من القوة ومقاومة التآكل |

| ال | 0.005 كحد أقصى | Deoxidizer |

| س | 0.05 ماكس | يحسن القابلية للآلات |

| سب | 0.20 كحد أقصى | يزيد من الصلابة |

| و | 0.005 كحد أقصى | Deoxidizer |

ملاحظات:

- في تحديد النحاس دقيقة، Cuck مع حساب و Cu + Ni.

- بالنسبة للمسبوكات المستمرة، يجب أن يكون P 1.5% كحد أقصى.

- تشمل NI Value Co.

- Cu + sum of named elements, 99.4% min. تمثل القيم الفردية الحد الأقصى.

الخواص الميكانيكية لـ C90810

| ملكية | قيمة | وحدة |

|---|

| صلابة برينل (حمولة 500 كجم) | 95 نموذجي | بي إتش إن |

| تقييم الماكينة | 20 | - |

| سمك 12-300 مم × عرض 200-2300 مم | 0.323 | رطل/بوصة مكعبة عند 68 درجة فهرنهايت (20 درجة مئوية) |

| إلى 500 درجة مئوية وتخفيف التوتر | 40.000 | رطل |

| قوة الغلة | 20.000 | رطل |

| استطالة | 20 | ٪ |

| معامل المرونة | 15 | × 10^6 رطل لكل بوصة مربعة |

الأداء في درجات حرارة مختلفة

| نطاق درجة الحرارة | خصائص الأداء | الاستخدام الموصى به |

|---|

| درجة حرارة منخفضة (-50 درجة مئوية إلى 0 درجة مئوية) | يحافظ على الليونة والمتانة | مناسب |

| درجة حرارة الغرفة (20 درجة مئوية إلى 25 درجة مئوية) | القوة المثلى ومقاومة التآكل | مثالي |

| درجة حرارة مرتفعة (100 درجة مئوية إلى 200 درجة مئوية) | يحتفظ بالقوة ولكن قد يتعرض لتليين طفيف | مقبول |

| درجة حرارة عالية (> 200 درجة مئوية) | لا ينصح باستخدامه لفترات طويلة | لا ينصح |

تطبيقات الصناعة

| صناعة | التطبيقات | الفوائد الرئيسية |

|---|

| الآلات الصناعية | المحامل، التروس، مهاوي، التروس الدودية | مقاومة عالية التآكل |

| البحرية | دفاعات المضخة، أجسام الصمامات | المقاومة للتآكل |

| بناء | مكونات الجسر المنقولة والأقراص الدوارة للجسور | القوة والمتانة |

| السيارات | حلقات المكبس | معامل الاحتكاك المنخفض |

| طاقة | تجهيزات البخار | مقاومة الحرارة |

| التعدين | البطانات الثقيلة | مقاومة التأثير |

| الفضاء | البطانات لمعدات الهبوط | قدرة تحميل عالية |

| النفط والغاز | مكونات الصمام | مقاومة التآكل في البيئات القاسية |

توافر الشكل والحجم

| شكل | نطاق الحجم | الطول القياسي |

|---|

| المواد الصلبة | 1 "إلى 6" OD | 144 ″ |

| الأنابيب | 1 "إلى 6" OD | 144 ″ |

| مستطيلات | ما يصل إلى 10 " | 144 ″ |

| لوحات | سمك يصل إلى 24 بوصة | 96 بوصة × 240 بوصة |

| قضبان | 0قطر .25 إلى 12 بوصة | 144 ″ |

| الأشكال المخصصة | حسب المتطلبات | يختلف |

النماذج المتاحة

| استمارة | الاستخدام النموذجي | التوفر |

|---|

| نصف تشطيب | مزيد من المعالجة | شائع |

| مخزون المطحنة | الاستخدام المباشر | متاحة على نطاق واسع |

| الأشكال القريبة من الشبكة | الحد الأدنى من الآلات | عند الطلب |

| مخزون البار | إلى 500 درجة مئوية وتخفيف التوتر | اساسي |

| لوحة | مكونات مسطحة كبيرة | شائع |

| الملف الشخصي أو الشكل الهيكلي | تطبيقات محددة | عند الطلب |

| من | مكونات عالية القوة | محدود |

| المسبوكات | الأشكال المعقدة | شائع |

معايير الإنتاج والامتثال

| المعيار/الامتثال | منطقة | الصلة |

|---|

| القانون الفيدرالي لمياه الشرب الآمنة – SDWA | الولايات المتحدة الأمريكية | سلامة المياه |

| S. 3874 التخفيض الفيدرالي في قانون مياه الشرب | الولايات المتحدة الأمريكية | محتوى الرصاص |

| كاليفورنيا AB1953 | كاليفورنيا، الولايات المتحدة الأمريكية | محتوى الرصاص |

| قانون فيرمونت 193 | فيرمونت، الولايات المتحدة الأمريكية | محتوى الرصاص |

| ASTM B505 | دولي | الصب المستمر لسبائك النحاس |

| ASTM B271 | دولي | مصبوبات الطرد المركزي لسبائك النحاس ذات القاعدة |

| ايزو 1338 | دولي | سبائك النحاس المصبوب |

| سعادة H5111 | D3 الصلب للأعمال الباردة لديه مقاومة تآكل عالية جدًا ضد التآكل الكاشطة والمواد اللاصقة بسبب الحجم الكبير للكربيدات الصلبة في مصفوفة الصلب | المسبوكات البرونزية |

المعايير والدرجات المقابلة في مختلف البلدان

| دولة | اساسي | الدرجة المقابلة |

|---|

| الولايات المتحدة الأمريكية | أدوات معالجة البلاستيك وقوالب الصب بالضغط | C90810 |

| D3 الصلب للأعمال الباردة لديه مقاومة تآكل عالية جدًا ضد التآكل الكاشطة والمواد اللاصقة بسبب الحجم الكبير للكربيدات الصلبة في مصفوفة الصلب | من | CuSn12 |

| D3 الصلب للأعمال الباردة لديه مقاومة تآكل عالية جدًا ضد التآكل الكاشطة والمواد اللاصقة بسبب الحجم الكبير للكربيدات الصلبة في مصفوفة الصلب | JIS | CAC704 |

| المملكة المتحدة | D3 الصلب للأعمال الباردة لديه مقاومة تآكل عالية جدًا ضد التآكل الكاشطة والمواد اللاصقة بسبب الحجم الكبير للكربيدات الصلبة في مصفوفة الصلب | HTB1 |

| فرنسا | نف | CuSn12 |

| إيطاليا | UNI | CuSn12 |

| روسيا | GOST | برو12 |

| D3 الصلب للأعمال الباردة لديه مقاومة تآكل عالية جدًا ضد التآكل الكاشطة والمواد اللاصقة بسبب الحجم الكبير للكربيدات الصلبة في مصفوفة الصلب | غيغابايت | ZCuSn12 |

| دولي | ISO | CuSn12 |

خصائص اللحام

| طريقة اللحام | ملاءمة | ملاحظات | سخن درجة الحرارة |

|---|

| لحام الغاز | جيد | استخدم قضيب حشو البرونز الفوسفوري | 150-200 درجة مئوية |

| لحام تيج | ممتاز | استخدام غاز التدريع الأرجون النقي | حسب الحاجة |

| أنا لحام | جيد | استخدم سلك الحشو البرونزي | حسب الحاجة |

| لحام العصا | عدل | استخدام الأقطاب البرونزية | حسب الحاجة |

| لحام المقاومة | مسكين | لا ينصح | غير متاح |

| لحام شعاع الإلكترون | جيد | للتطبيقات الدقيقة | حسب الحاجة |

| اللحام بالليزر | عدل | يتطلب مراقبة دقيقة | حسب الحاجة |

خصائص المعالجة

| معالجة | ملاءمة | ملاحظات | الاعتبار الرئيسي |

|---|

| إلى 500 درجة مئوية وتخفيف التوتر | جيد | تصنيف القدرة على الماكينات 20 | اختيار الأداة |

| تشكيل | عدل | قابلية تشكيل محدودة بسبب المحتوى العالي من القصدير | تجنب التشوه المفرط |

| الخصائص الفيزيائية والميكانيكية العامة في درجة الحرارة المحيطة | مسكين | لا ينصح | غير متاح |

| صب | ممتاز | مثالية لصب الرمل والطرد المركزي | معدل التبريد المناسب |

| البثق | مسكين | لا مقذوف عادة | غير متاح |

| رسم عميق | مسكين | ليونة محدودة | لا ينصح |

| الغزل | عدل | ممكن مع التقنيات المناسبة | تجنب تصلب العمل |

| التطرق | جيد | مناسبة للتحجيم الدقيق | ارتداء الأداة |

خصائص التلميع

| طريقة التلميع | نتيجة | المواد الكاشطة الموصى بها |

|---|

| التلميع الميكانيكي | تشطيب جيد للسطح يمكن تحقيقه | مركبات الألومينا أو الماس |

| التلميع الكيميائي | نتائج معتدلة | حلول خاصة |

| توحيات كهربائية | ممتاز للانتهاء من اللمعان العالي | الشوارد القائمة على حمض الفوسفوريك |

| التلاعب | لمعان عالي ممكن | عجلات من القماش الناعم مع مادة كاشطة دقيقة |

| اللف | الانتهاء من الدقة | مركبات كربيد الماس أو السيليكون |

| شحذ | جيد للأسطح الأسطوانية | الحجارة الكاشطة المستعبدين |

الخصائص الميكانيكية

| الخصائص الميكانيكية | نطاق درجة الحرارة | غاية | طريقة التبريد |

|---|

| التلدين | 550-650 درجة مئوية | تخفيف التوتر وتنعيمه | التبريد البطيء |

| علاج الحل | لا ينطبق | C90810 غير قابل للمعالجة الحرارية | غير متاح |

| تصلب السن | لا ينطبق | C90810 ليس قابلاً للتصلب مع تقدم العمر | غير متاح |

| تخفيف التوتر | 260-370 درجة مئوية | تقليل الضغوط الداخلية | تبريد الهواء |

| التطبيع | لا يتم تنفيذها عادةً | غير متاح | غير متاح |

| التبريد | لا ينصح | قد يسبب تشويه | غير متاح |

خصائص المعالجة الباردة

| معالجة | ملاءمة | ملاحظات | اقتراح بديل |

|---|

| العمل الباردة | محدود | محتوى القصدير العالي يقلل من الليونة | النظر في العمل الساخن إذا لزم الأمر |

| الرسم البارد | مسكين | لا ينصح | استخدام الآلات بدلا من ذلك |

| المتداول البارد | مسكين | لا ينصح | النظر في النماذج المصبوبة أو الآلية |

| العنوان البارد | غير مناسب | هشة للغاية | استخدام الآلات أو الصب |

| تزوير الباردة | غير مناسب | يفتقر إلى الليونة اللازمة | النظر في تزوير الساخنة أو الصب |

| تسديدة | عدل | يمكن تحسين خصائص السطح | استخدم بحذر |

مزايا وعيوب C90810

| مزايا | سلبيات | اعتبارات |

|---|

| قوة عالية | قابلية تشكيل محدودة | تصميم للحد الأدنى من التشكيل |

| مقاومة تآكل ممتازة | تكلفة أعلى مقارنة ببعض البرونزيات | النظر في التطبيقات الهامة |

| مقاومة جيدة للتآكل | غير مناسب للتطبيقات عالية السرعة | يُستخدم في إعدادات السرعة المنخفضة إلى المتوسطة |

| معامل الاحتكاك المنخفض | قدرة محدودة على العمل البارد | تصميم لأشكال مصبوبة أو آلية |

| مناسب للأحمال الثقيلة | غير قابلة للعلاج بالحرارة | اختر للتطبيقات التي لا تتطلب المعالجة الحرارية |

| آلية جيدة | كثافة عالية نسبيا | النظر في الوزن في التصميم |

| خصائص تحمل ممتازة | عرضة لآفة القصدير في درجات حرارة منخفضة للغاية | تجنب التعرض لفترة طويلة أقل من 13 درجة مئوية |

| الاستقرار الأبعاد الجيدة | يمكن أن يكون من الصعب اللحام | استخدام تقنيات اللحام المناسبة |

| مقاومة للتآكل بمياه البحر | ليست قوية مثل الفولاذ | استخدم في ظروف التحميل المناسبة |

| نفاذية مغناطيسية منخفضة | تكلفة أعلى من النحاس | تبرير التكلفة مع متطلبات الأداء |

منتجات مماثلة

| سبيكة | رقم UNS | التركيبة الرئيسية | الاختلافات الرئيسية |

|---|

| C90700 | C90700 | CU-SN-ZN | القصدير السفلي، ومحتوى الزنك العالي |

| C91100 | C91100 | مع-Sn | محتوى أعلى من القصدير، لا يوجد رصاص |

| C93200 | C93200 | النحاس والقصدير والرصاص | محتوى أعلى من الرصاص لتحسين إمكانية التشغيل الآلي |

| C95400 | C95400 | مع متابعة | برونز الألومنيوم مع خصائص مختلفة |

| C95500 | C95500 | cu-al-ni-fees | برونز النيكل والألومنيوم بقوة أعلى |

| C86300 | C86300 | النحاس-MN-NI-FE | برونز المنغنيز ذو قوة أعلى |

| C92200 | C92200 | CU-SN-PB-ZN | مسدس Navy M معدني بتركيبة مختلفة |

مقارنة C90810 مع المنتجات المماثلة

| ملكية | C90810 | C90700 | C91100 | C93200 | C95400 |

|---|

| قوة الشد (رطل لكل بوصة مربعة) | 40.000 | 36000 | 45000 | 35000 | 90.000 |

| قوة الخضوع (رطل لكل بوصة مربعة) | 20.000 | 18000 | 25000 | 18000 | 45000 |

| استطالة (٪) | 20 | 25 | 15 | 20 | 15 |

| صلابة برينل | 95 | 70 | 100 | 65 | 190 |

| المقاومة للتآكل | ممتاز | جيد | ممتاز | جيد | ممتاز |

| آلية | جيد | جيد جدًا | عدل | ممتاز | عدل |

| قابلية اللحام | عدل | جيد | عدل | مسكين | جيد |

| ارتداء المقاومة | ممتاز | جيد | ممتاز | جيد | ممتاز |

| يكلف | عالي | معتدل | عالية جدًا | معتدل | عالي |

| التطبيقات النموذجية | المحامل الشاقة | للأغراض العامة | محامل عالية التحميل | البطانات والمحامل | المكونات البحرية |

خاتمة:

C90810 High Tin Bronze هي سبيكة متخصصة توفر مزيجًا فريدًا من الخصائص، مما يجعلها لا تقدر بثمن في التطبيقات الصناعية المختلفة. يساهم محتواه العالي من القصدير في القوة الممتازة، ومقاومة التآكل، ومقاومة التآكل، خاصة في إعدادات التحميل الثقيل والسرعة المنخفضة. في حين أن لديه قيود في قابلية التشكيل والتطبيقات في درجات الحرارة العالية، فإن C90810 يتفوق في صناعات مثل الهندسة البحرية والآلات الصناعية والبناء.

ويتجلى تنوع السبائك في مجموعتها الواسعة من الأشكال والأحجام المتاحة، والالتزام بالمعايير الدولية، وقابلية التصنيع الجيدة. ومع ذلك، يجب على المصممين والمهندسين مراعاة خصائصه المحددة، مثل القدرة المحدودة على العمل البارد وخيارات المعالجة الحرارية، عند دمج C90810 في مشاريعهم.

بالمقارنة مع السبائك المماثلة، تتميز C90810 بتوازن القوة، مقاومة التآكل، ومقاومة التآكل. إن خصائصه الفريدة تجعله خيارًا مثاليًا للتطبيقات التي تكون فيها هذه الخصائص حاسمة، مما يبرر تكلفته المرتفعة في المكونات الحيوية.

باختصار، لا يزال البرونز عالي القصدير C90810 مادة قيمة في الهندسة الحديثة، حيث يقدم أداءً موثوقًا في البيئات الصعبة حيث قد تفشل السبائك الأخرى.