مقدمة

S45C و 42CRMO4 هما صفان من الصلب الكربوني والسبائك المستخدمة على نطاق واسع في مختلف تطبيقات الهندسة والتصنيع. توفر هذه المقالة مقارنة شاملة مع هاتين المادتين ، مع التركيز على تركيباتها الكيميائية ، والخصائص الميكانيكية ، واستجابات المعالجة الحرارية ، والتطبيقات ، ومزاياها وعيوبها.

درجة حرارة التقسية

يعد التركيب الكيميائي لكل من S45C و 42CRMO4 أمرًا حيويًا في تحديد خصائصهما الميكانيكية والأداء الكلي.

| عنصر | تكوين S45C (٪) | تكوين 42CRMO4 (٪) |

|---|---|---|

| الكربون (ج) | 0.42% – 0.48% | 0.38 ٪ - 0.45 ٪ |

| المنغنيز (من) | 0.60% – 0.90% | 0.60% – 0.90% |

| الكروم (الكروم) | - | 0.90 ٪ - 1.20 ٪ |

| الموليبدينوم (مو) | - | 0.15 ٪ - 0.30 ٪ |

| الفوسفور (ف) | 0.03% كحد أقصى | 0.03% كحد أقصى |

| الكبريت (S) | 0.03% كحد أقصى | 0.03% كحد أقصى |

شرح التكوين الكيميائي

- الكربون (ج): وصف شريط الصلب C45 يحتوي على محتوى كربون أعلى قليلاً من 42 كرمو 4، المساهمة في خصائصها. محتوى الكربون الأعلى عادة ما يعزز الصلابة والقوة.

- الكروم (CR) و molybdenum (MO): 42Crmo4 يحتوي على الكروم والموليبدينوم ، مما يحسن الصلابة ، ومقاومة التآكل ، والصلابة ، مما يجعلها مناسبة للتطبيقات الديناميكية وعالية الإجهاد.

- المنغنيز (من): كلا الدرجتين لهما محتوى منغنيز مماثل ، مما يساعد في إزالة الأكسدة ويحسن قابلية الصلابة.

الخصائص الميكانيكية

تلعب الخصائص الميكانيكية دورًا مهمًا في تحديد الأداء تحت الحمل والإجهاد.

| ملكية | وصف شريط الصلب C45 | 42 كرمو 4 |

|---|---|---|

| قوة الخضوع (ميجا باسكال) | حوالي 355 ميجا باسكال | ما يقرب من 600 - 800 ميجا باسكال |

| قوة الشد (MPa) | 570 - 700 ميجا باسكال | 700 - 900 ميجا باسكال |

| استطالة (٪) | 14% (الحد الأدنى) | 12% (الحد الأدنى) |

| صلابة (HB) | 170 - 210 غ | 250 - 300 HB |

شرح مفصل للخواص الميكانيكية

- قوة الغلة: 42CRMO4 لديه قوة عائد أعلى بكثير من S45C ، مما يجعلها أكثر ملاءمة للتطبيقات عالية الإجهاد.

- إلى 500 درجة مئوية وتخفيف التوتر: وبالمثل ، فإن قوة الشد من 42CrMO4 تتجاوز قوة S45C ، مما يشير إلى قدرة أفضل على الحمل.

- استطالة: S45C لديها خصائص استطالة أفضل ، مما يسمح لها بالخضوع لمزيد من تشوه البلاستيك مقارنة بـ 42CRMO4.

- سمك 12-300 مم × عرض 200-2300 مم: 42Crmo4 عمومًا أصعب من S45C ، مما يساهم في مقاومة التآكل والمتانة.

ردود المعالجة الحرارية

يمكن أن تؤثر عملية معالجة الحرارة على الخواص الميكانيكية لكلا الدرجتين.

| نوع المعالجة الحرارية | وصف شريط الصلب C45 | 42 كرمو 4 |

|---|---|---|

| التبريد | مناسبة للتصلب | مناسبة للتصلب |

| تلطيف | يقلل من الهشاشة مع الحفاظ على القوة | يحسن الصلابة مع تعزيز الصلابة |

شرح المعالجة الحرارية

- التبريد: يمكن إخماد كلا المادتين لزيادة صلابة ، ولكن 42CRMO4 تميل إلى تحقيق صلابة أكبر بسبب عناصرها التي تنص على سبائك.

- تلطيف: التخفيف ضروري بعد التبريد لتخفيف الضغوط. تستفيد كلتا المادتين من التخفيف ، مع تعزيز 42CRMO4 من الصلابة مع الحفاظ على الصلابة.

التطبيقات

يتم استخدام S45C و 42CRMO4 في مجموعة متنوعة من التطبيقات حسب خصائصها.

| تطبيق | وصف شريط الصلب C45 | 42 كرمو 4 |

|---|---|---|

| التروس | شائعة الاستخدام | تستخدم في التروس عالية الضغط |

| مهاوي | مناسب للاستخدام العام | مهاوي عالية الأداء |

| أجزاء الآلة | الأجزاء الهندسية العامة | المكونات الحرجة التي تتطلب قوة عالية |

| أدوات | لا تستخدم عادة | ينطبق على أدوات القطع ويموت |

| مكونات السيارات | كثيرا ما تستخدم | شائع الاستخدام في المحاور والعمود المرفقية |

شرح التطبيقات

- وصف شريط الصلب C45: إن قابليتها الجيدة والخصائص المتوازنة تجعلها مناسبة للتطبيقات الهندسية العامة.

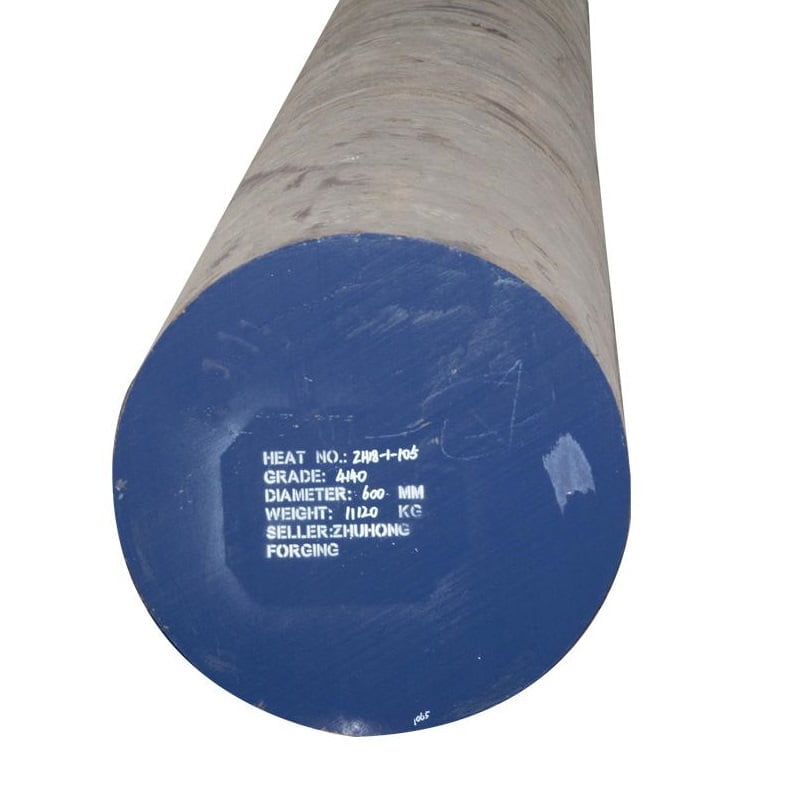

- 42 كرمو 4: إن عناصر صناعة السبائك والقوة العالية تجعلها مناسبة للتطبيقات الديناميكية ، بما في ذلك أجزاء السيارات حيث تكون المتانة ضرورية.

المميزات والعيوب

يتمتع كل من S45C و 42CRMO4 بمزاياها وعيوبها المحددة.

| وجه | وصف شريط الصلب C45 | 42 كرمو 4 |

|---|---|---|

| مزايا | – قابلية تشغيل جيدة | - قوة وصلابة أعلى |

| - فعالة من حيث التكلفة للتطبيقات العامة | - صلابة ممتازة ومقاومة التعب | |

| - خصائص متوازنة | - مناسبة للبيئات عالية الضغط | |

| سلبيات | - أقل قوة مقارنة بـ 42Crmo4 | – تكلفة أعلى مقارنة بـ S45C |

| - صلابة محدودة | - أكثر تحديا للآلة |

شرح مفصل للمزايا والعيوب

- مزايا S45C: إن قابليتها الجيدة وفعالية التكلفة تجعلها مناسبة لمختلف التطبيقات الهندسية.

- عيوب S45C: انخفاض القوة والصلابة قد يحد من فعاليته في التطبيقات عالية الضغط.

- 42CRMO4 مزايا: القوة المعززة والصلابة والمقاومة للإرهاق تجعلها مثالية للتطبيقات الصعبة.

- 42CRMO4 العيوب: زيادة صلابة يمكن أن تعقد عمليات الآلات ، وتكلفةها أعلى مقارنة بـ S45C.

خاتمة

يعتمد الاختيار بين S45C و 42CRMO4 على المتطلبات المحددة للتطبيق. يعد S45C مناسبًا للاستخدام الهندسي العام ، حيث يوفر توازنًا في القوة وقابلية القابلية للآلات ، في حين أن 42CRMO4 مفضل لقوته العالية والصلابة والملاءمة في التطبيقات الديناميكية. إن فهم اختلافاتهم في التركيب الكيميائي ، والخصائص الميكانيكية ، واستجابات المعالجة الحرارية ، والتطبيقات ستساعد المهندسين والمصنعين في إنشاء اختيارات مستنيرة لتلبية احتياجاتهم من مشروعهم.